6. Reinstall the ball valve extension, push plate and hex head bolt. Do not use PTFE

tape.

7. With a suitable wrench, reinstall grey PVC elbow (drench hose assembly).

8. Reinstall eyewash wye by hand tightening.

Note: This is a non-pressure containing part and is sealed with a rubber gasket.

Hand tight is more than adequate to prevent leaks.

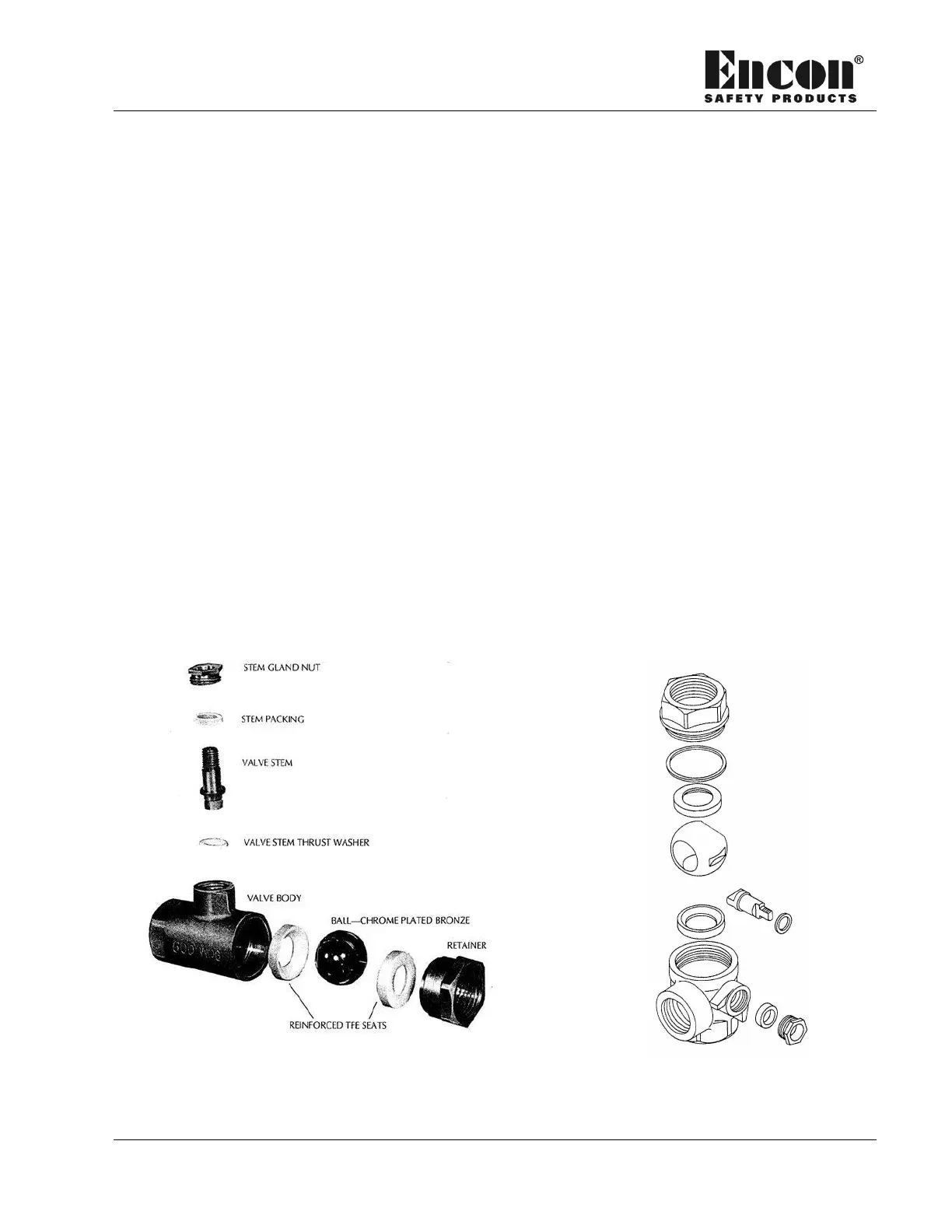

4.5 Ball Valves

Complete the following procedure if a ball valve is leaking.

To maintain the ball valves:

1. If applicable, remove the covers, insulation, and heat trace cable as described in

“4.2. Removing and Replacing ABS Covers to Access Components” on page 4-1.

2. Adjust the packing gland by tightening the packing gland and/or repack the valve

as required.

3. Should the valve leak by the seals, remove it from the pipe and disassemble the

valve as described in “4.5.1 Eyewash Ball Valve” on page 4-6. Inspect the seals

for debris permeation and the ball for scoring. Refer to “6 Spare Parts” on page 6-

1 for Ball Valve Repair Kit.

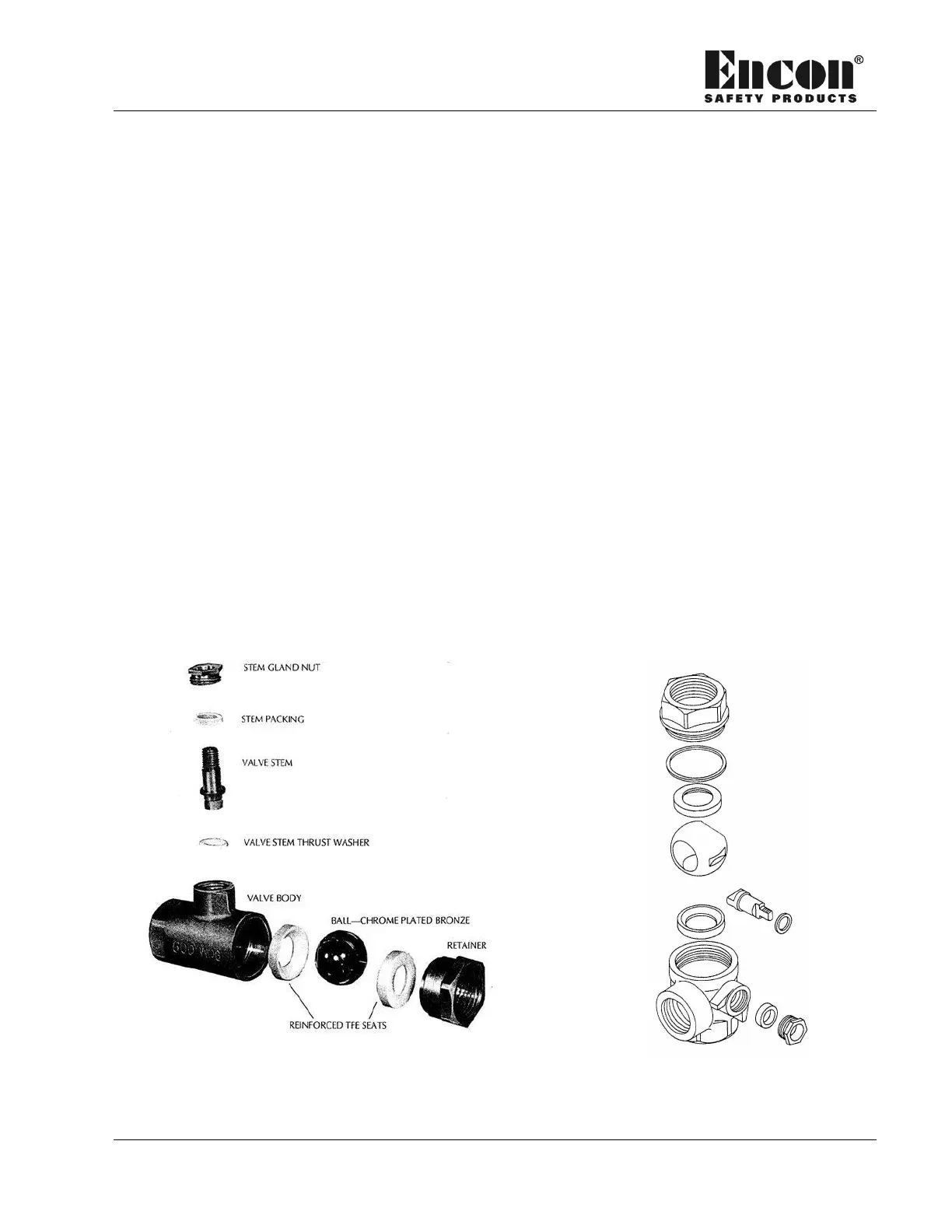

2-Way Assembly

3-Way Assembly

Figure 4-3. Ball Valve Assembly — 2-Way and 3-Way

Loading...

Loading...