Turbimax CUS51D

Endress+Hauser 11

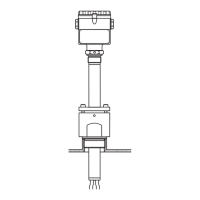

Pipe installation The following figure illustrates various installation positions in pipes and indicates whether they are permitted

or not.

a0013011

Orientation and installation positions (with retractable assembly CUA451)

• The pipeline diameter must be at least 100 mm (4") if reflective materials (e.g. stainless steel) are used. An

onsite calibration is recommended.

• Install the sensor in places with uniform flow conditions.

• The best installation location is in the ascending pipe (it. 1). Installation is also possible in the horizontal pipe

(it. 5).

• Do not install the sensor in places where air may collect or foam bubbles form (it. 3) or where suspended

particles may settle (it. 2).

• Avoid installation in the down pipe (it. 4).

• Turbidity measurement < 200 FNU will result in erroneous measuring results due to backscattering of pipe

wall. Therefore a multipoint calibration is recommended.

• Avoid installations behind pressure reduction steps which can outgas.

Environment

Ambient temperature -20 to 60 °C (-4 to 140 °F)

Storage temperatur -20 to 70 °C (-4 to 158 °F)

Ingress protection IP 68 (test conditions: 1 m (3.3 ft) water column during 60 days, 1 mol/l KCl)

Process

Process temperature -5 to 50 °C (23 to 120 °F)

max. 80 °C (175 °F) short term(1 h)

Process pressure 0.5 to 10 bar (7 to 145 psi) absolute

Minimum flow No minimum flow required.

Make sure that there is a sufficient turbulence for solids with a tendency to sedimentation.

Loading...

Loading...