Accel CS Boiler - Gas Heat - Eighth Edition – January, 2015 15

VENTING MATERIALS AND OPTIONS

The Accel CS Boiler can generate exiting flue gas temperatures between room temperature and 230

o

F, depending on

the modulated firing rate and the boiler water temperature. The Accel CS boiler can be safely vented using a variety of

venting materials. Approved materials include stainless steel, such as 316, 316L, 316Ti or AL 29-4C. Plastic venting

products made from polypropylene are approved. Plastic venting products made from other plastics, such as PVC, CPVC,

or ABS are not approved. Any of the plastic pipe materials may be safely used for air intake piping, but not for venting.

The venting materials for the Accel CS boiler may be obtained from Energy Kinetics, from Z-Flex, from Centrotherm or

from DuraVent. The Z-Flex, Centrotherm and DuraVent products may also be obtained from any stocking distributor that

carries these products.

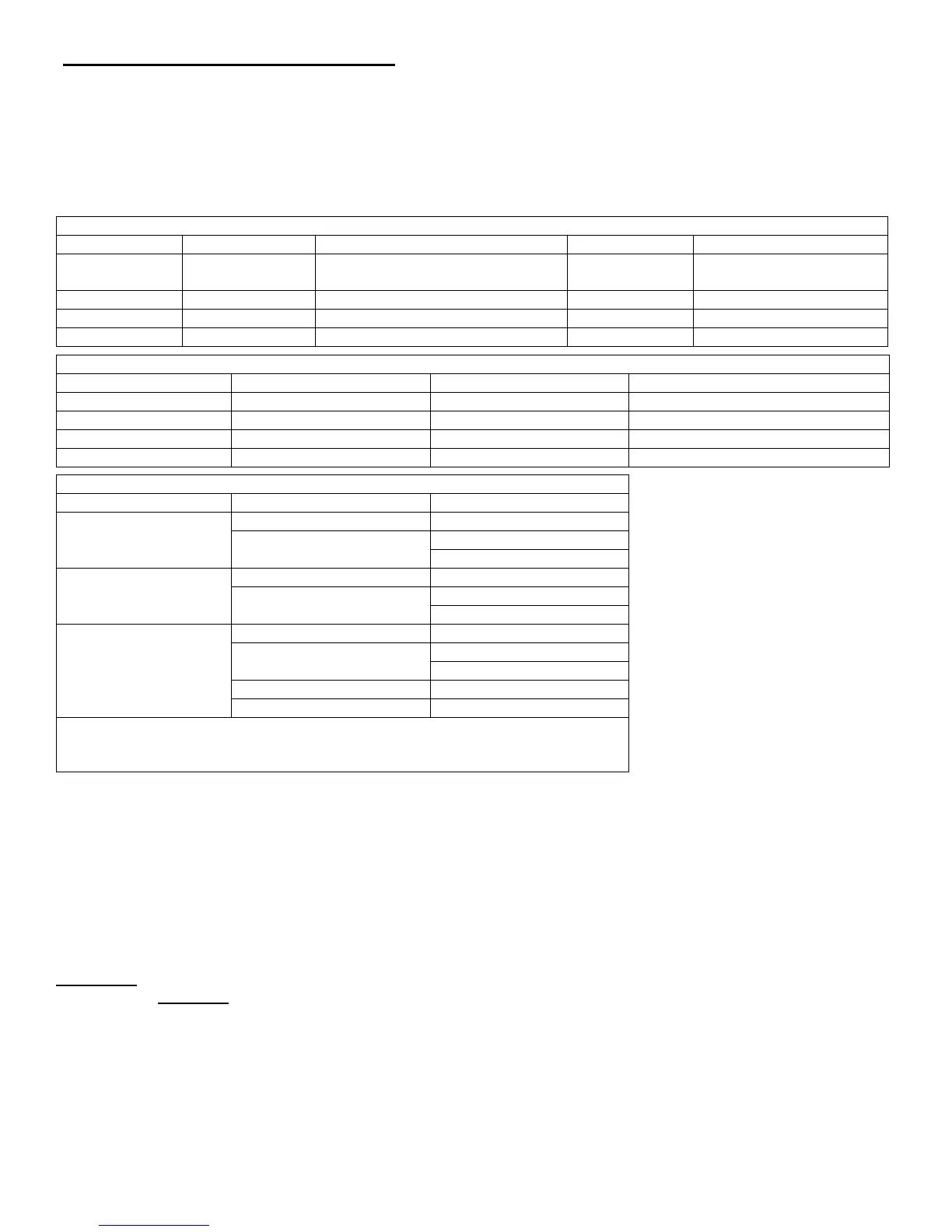

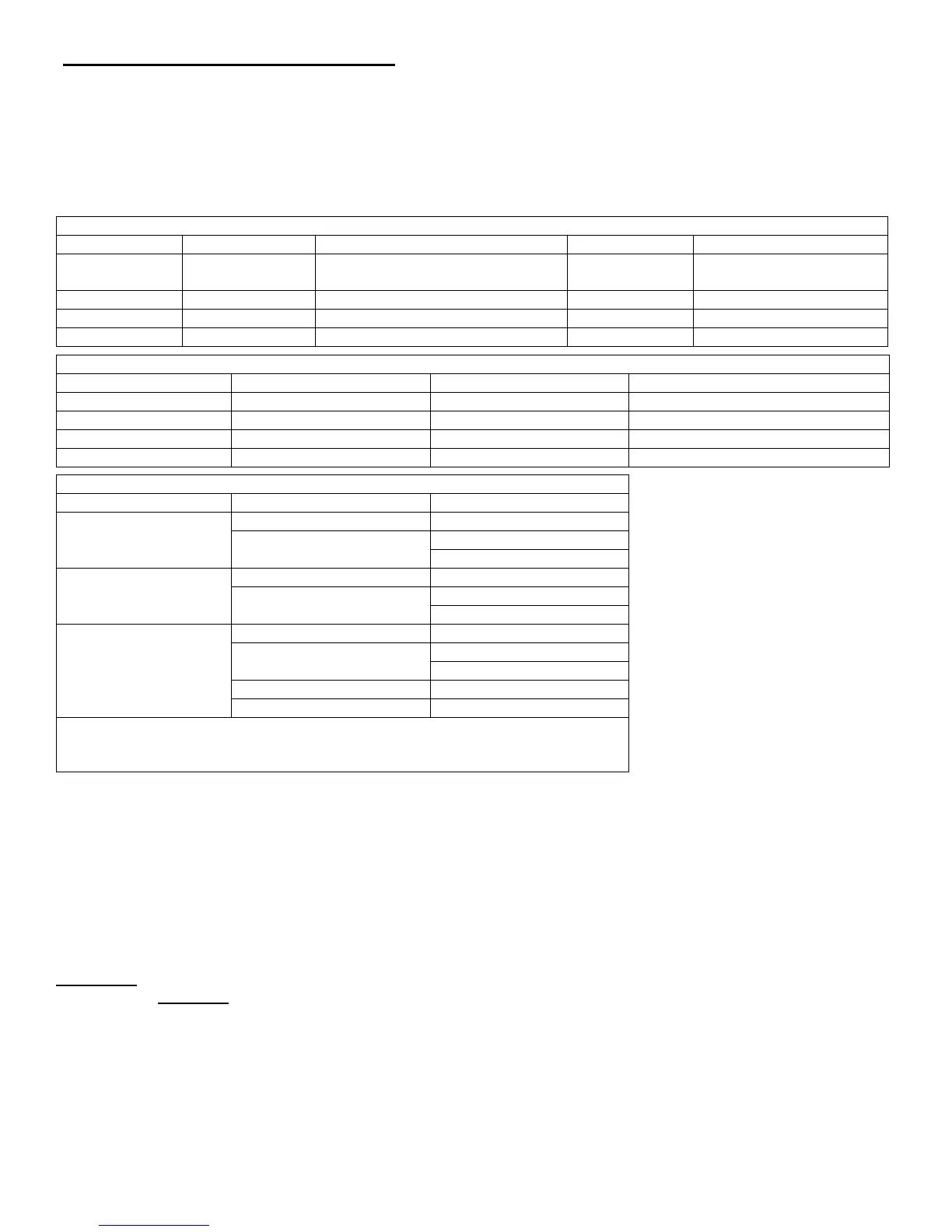

Where to obtain venting materials

Energy Kinetics Stainless steel

Energy Kinetics EK1 or EK2

sidewall vent kit

800-323-2066 www.EnergyKinetics.com

Venting material must be Listed by a nationally recognized testing agency.

Approved Vent and Air Inlet Pipe Material

Appliance Adapter

1

Stainless Steel (AL29-4C)

Polypropylene

Vent Pipe & Fittings

1

Stainless Steel (AL29-4C)

Polypropylene (PPs)

Air Inlet Pipe & Fittings

Polypropylene (PPs)

1. Only Stainless Steel and Polypropylene material permitted for Venting

2. Use of PVC, CPVC, or ABS is only allowed for Air Inlet piping

The Accel CS boiler may be vented using several different options, materials, and methods.

1) Energy Kinetics EK1 or EK2 sidewall vent kit using 3” Z-Vent III piping.

2) Sidewall venting using Polypropylene in 2”, 3” or 4” diameters.

a) Two pipe with low profile termination (2” & 3” only).

b) Two pipe with snorkel termination.

c) Concentric through the wall (2/4”, 3/5” or 4/6”).

3) Vertically with Polypropylene in 2”, 3” or 4” diameters.

a) Using a chimney as a chase.

WARNING: Sidewall vent systems must have outside air connected to the boiler and both intake and vent hood must be

located on the same side of the structure. Vertically vented systems should have outside air connected to the boiler.

The Accel CS boilers have a flue collar made of Z-Vent III AL29-4C stainless steel - 3” on the EK1C / 4” on the EK2C &

EK3C. If the boiler is vented using Z-Vent III stainless steel vent materials, then the venting may be directly connected to

the flue outlet. If the boiler is vented using either of the two polypropylene materials, then a stainless steel to polypropylene

appliance adapter is required. The fresh air inlet pipe size at the boiler is 3” on the EK1C / 4” on the EK2C & EK3C. PVC

pipe may be used for air inlet only. When using one of the approved polypropylene terminations, it may be necessary to

adapt from PVC to polypropylene using the appropriately sized PVC to polypropylene adapter.

Loading...

Loading...