3

FIGURE 2 - SPECIFICATIONS

Used

with

cylinder

Usable Oil

Capacity

cm³

[in³]

Model

Number

Pressure Rating

bar [psi]

Oil Displacement

per Stroke

cm³ [in³]

Max.

Handle

Eort

kg

[lbs]

Piston

Stroke

mm

[inch]

kg

[lbs]

1

st

stage 2

nd

stage 1

st

stage 2

nd

stage

Single-

Acting

492

[30]

P-392FP

15

[220]

700

[10,000]

11,26

[.687]

2,47

[.151]

42

[93]

25,4

1,00

7,0

[15.4]

5.2 Using Two-Speed Pumps

These pumps provide 2-stage flow. Under no-load, the

pump operates in the high flow first stage for rapid

advance. When the load is contacted, the pump

automatically shifts to the second stage for building

pressure.

NOTE: For best performance, operate pump handle at

moderate speed during the high flow first stage. Rapid

handle speed in the first stage will prevent the pump from

delivering full volume of oil.

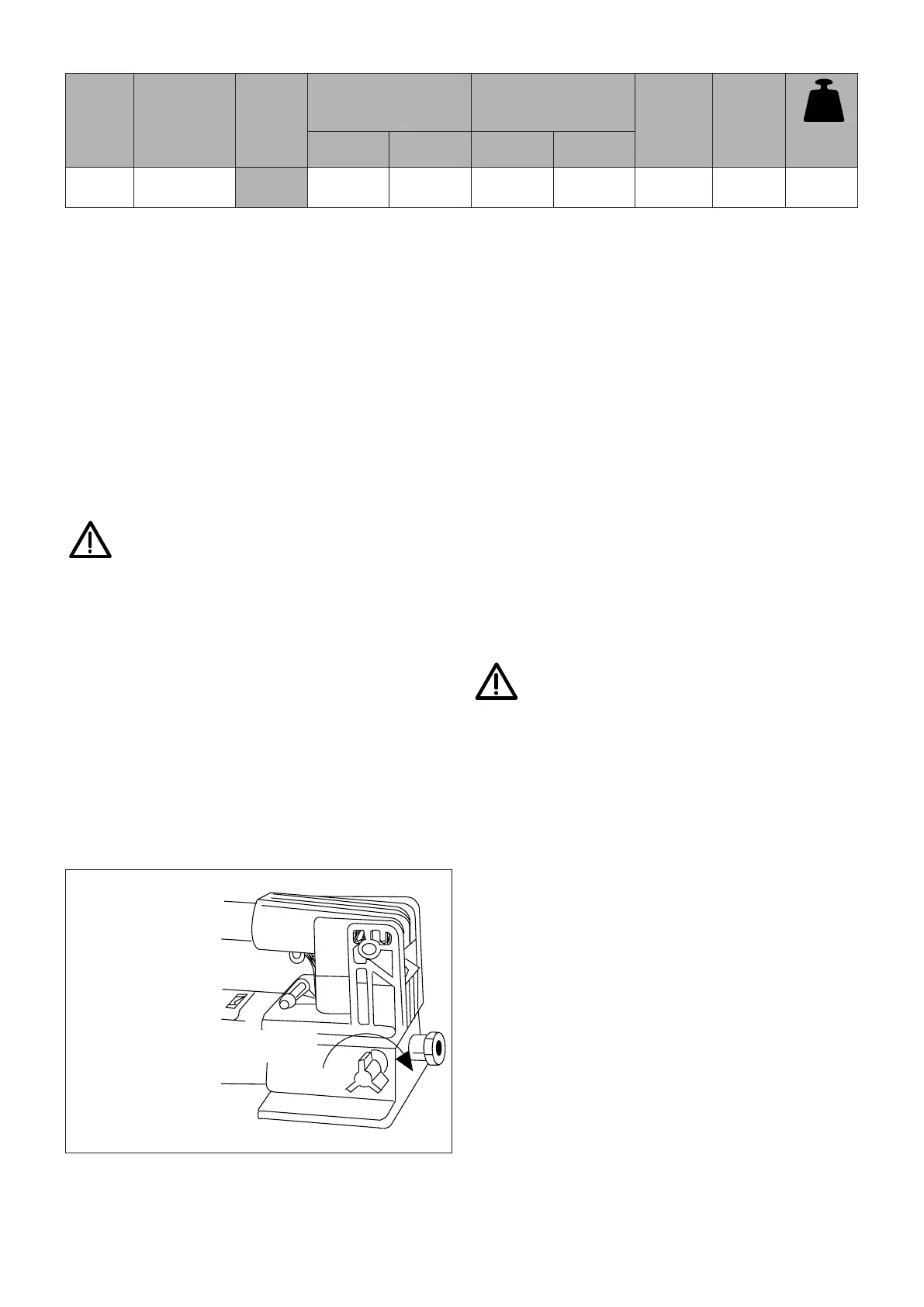

5.3 Single-Acting Applications with Release Valve

1. Close release valve by turning clockwise, as shown in

Figure 3.

CAUTION: Close release valve finger tight ONLY.

Using tools on release valve can damage it and

cause the pump to malfunction.

2. Operate pump handle to deliver hydraulic power to

system. Pressure will be maintained until release valve

is opened.

3. Open release valve (turn counter-clockwise) to release

pressure, allowing oil to flow back to the reservoir.

5.4 Relief Valve Adjustment

The pumps contains a factory set relief valve to prevent

overpressurization of the system. Lower pressure settings

can be obtained. Contact your Enerpac authorized service

center.

6.0 AIR REMOVAL

Removing air from the hydraulic system will help the

cylinder to advance and retract smoothly (see figure 4).

Release valve

Figure 3

6.1 Pump With Single-Acting Cylinder

1. Vent pump reservoir (for vented pumps only) and close

release valve.

2. Position pump at higher elevation than cylinder.

3. Position cylinder with the plunger end down (up if using

pull cylinder). See Figure 4.

4. Operate pump to fully extend the cylinder (retract if us-

ing pull cylinder).

5. Open release valve to retract cylinder (extend if a pull

cylinder). This will force the trapped air to move up to

the pump reservoir.

6. Repeat the above steps as necessary.

7. Add oil if necessary. See paragraph 7.1 (page 3).

8. Return vent/fill cap to operating position.

7.0 MAINTENANCE

Use only Enerpac hydraulic oil with these pumps to

promote long pump life and to protect your warranty. Viton

and EPR seal kits are available for some hand pumps.

Contact your Enerpac representative for more information

7.1 Adding oil to pump

Check oil level regularly.

WARNING: Always add oil with cylinders fully

retracted (extended if pull cylinders) or the

system will contain more oil than the reservoir

can hold.

1. Remove vent/fill cap from reservoir.

2. Fill reservoir only to level mark shown on pump.

3. Remove air from system if necessary. See page 3.

Recheck oil level after removing air.

4. Return vent/fill cap to proper position.

NOTE: Non-vented hand pumps require air in the reservoir

to function properly. If the reservoir is completely filled, a

vacuum will form, preventing oil from flowing out of the

pump.

7.2 Keeping Oil Lines Clean

When coupler halves are disconnected, always screw on

dust caps. Use every precaution to guard unit against

entrance of dirt because foreign matter may cause pump,

cylinder, or valve failure.

7.3 Lubricating the Pump

To extend pump life and improve performance, lubricate the

beam pin (A), cross pin (B), and piston head (C) regularly,

using roller bearing grease. See Figure 5 on page 4.

Loading...

Loading...