EVR AUTOMATIC RECLOSER http://www.entecene.co.kr

11

ENHANCED TECHNOLOGY

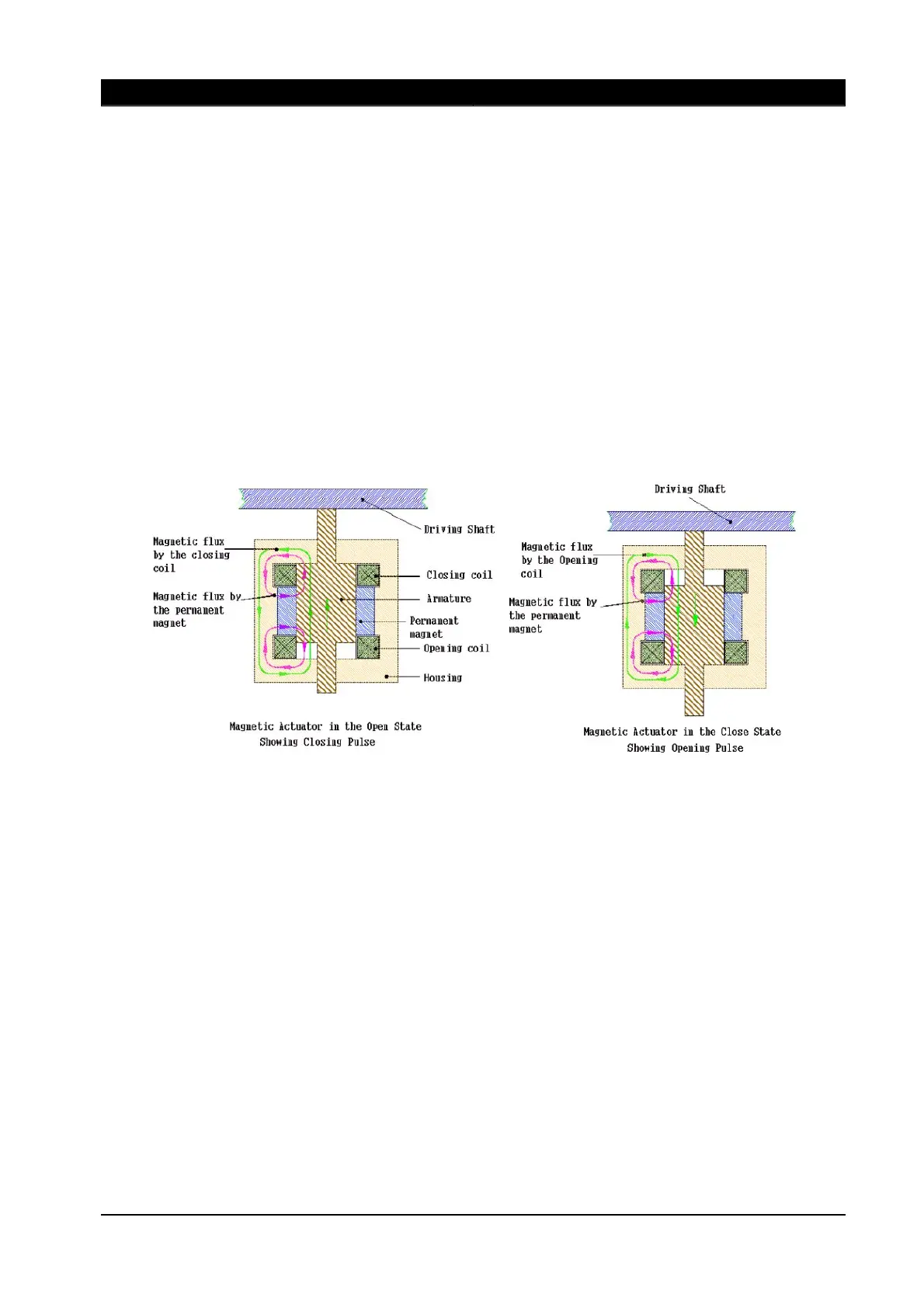

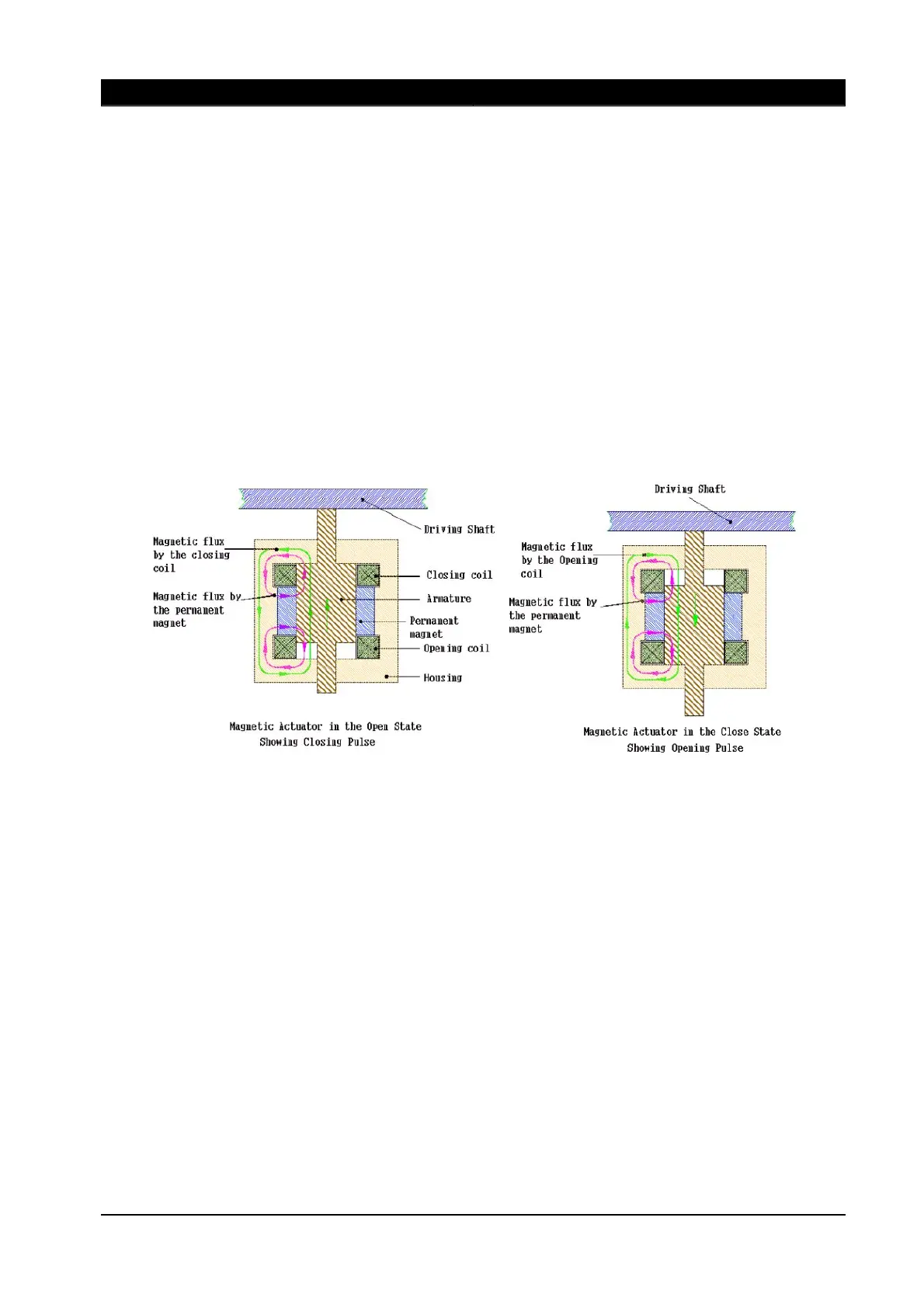

The permanent magnetic actuator mechanism has just one moving part.

Thus the dramatic reduction in part gives a corresponding increase in reliability. Especially, as the

actuator uses magnetic latching and uses trip and close coil separately, the actuator consists of the

fewest components and can provides zero-maintenance operation.

The actuator driving arm is made of high strength aluminum alloy and delivers force to the

interrupter. When pulse current flows into the close coil, the plunger of magnetic actuator is moved

by the induced magnetic force to drive the interrupter to close position, and the actuator is then held

in the closed position. In contrast, when pulse current flows into the trip coil, the plunger is

released from the magnetic latch and the interrupter is moved to trip position.

Figure 3-2. The principles of magnetic actuator operation

3.3. BUSHING

Bushing is mounted on the top of the recloser tank and supplied with either porcelain or polymeric

bushing(EPR or Silicone rubber) depending upon user’s requirements.

The ring core CT is mounted on the lower part of bushing inside of the recloser tank arranged at the

fixed position of interrupter and senses the current flow.

This current information is transmitted to the micro-processor based relay via the multi-core cable.

Capacitor voltage divider (CVD) is available in case of using polymeric bushing to measure and

sense the secondary voltage for signaling use.

Loading...

Loading...