7

steady penetration and a constant, even rotation speed with no

jamming (see table).

N�B. It is important that the feed force be adapted to suit the

weight of the drill string. When drilling deep holes, this requires

control facilities for “negative feeding”, a so-called “holdback”

function.

Rotation speed

In hard rock, the rotation speed for COP 32/42 should be set

between 20-35 r/min, depending on the hammer size and bit

diameter (the larger the bit diameter, the slower the speed). The

upper limit generally produces the best penetration rate. In very

abrasive rock formations, however, the rotation speed should be

reduced to avoid excessive wear of the drill bit.

When drilling in softer rock or in the case of the COP 42, when

drilling with high air pressure (above 16 bar) in non-abrasive for-

mations, higher rotation speed may be used. The following should

be noted:

Rotation speed – recommendations ( r/min)

Penetration rate

Rock characteristics

COP 32

ø 90 mm

COP 42

ø 115 mm

0,7 - 1 m/min.

Soft, abrasive rock

Soft, non abrasive rock

(Air pressure above 16 bar)

40-55

–

35–50

35–70

0,4 - 0,7 m/min.

Medium-hard,

abrasive rock

non abrasive rock

(Air pressure above 16 bar)

30–40

–

25–35

25–55

<0,4 m/min.

Hard, abrasive rock

Hard, non abrasive rock

(Air pressure above 16 bar)

25–35

–

20–30

20–50

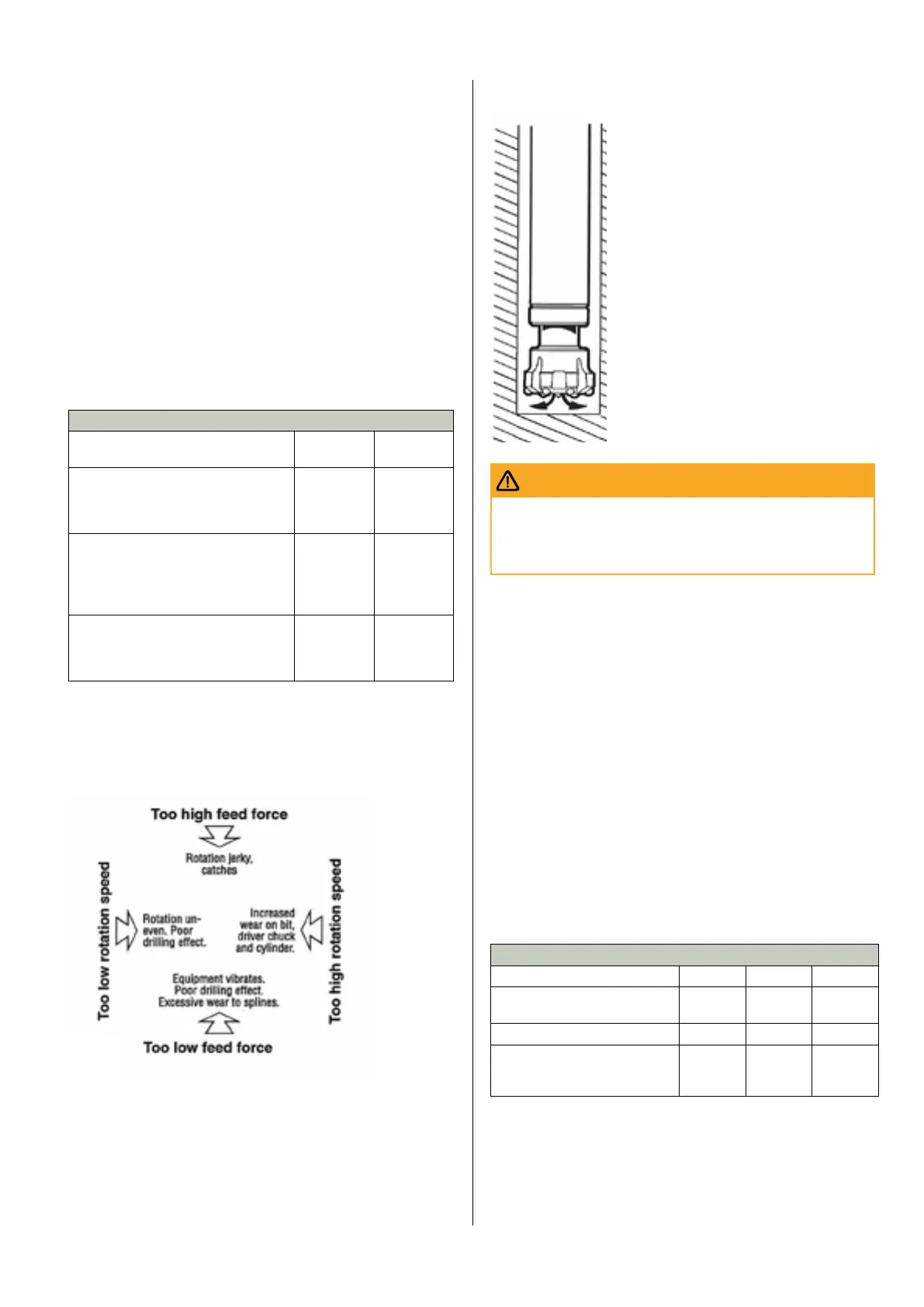

Too high a rotation speed will cause increased wear to the drill bit,

hammer and drill pipes. Stresses to the feed and rotation unit will

also increase.

Too low a rotation speed results in a poor drilling output and

uneven operation.

Flushing — Air-blowing

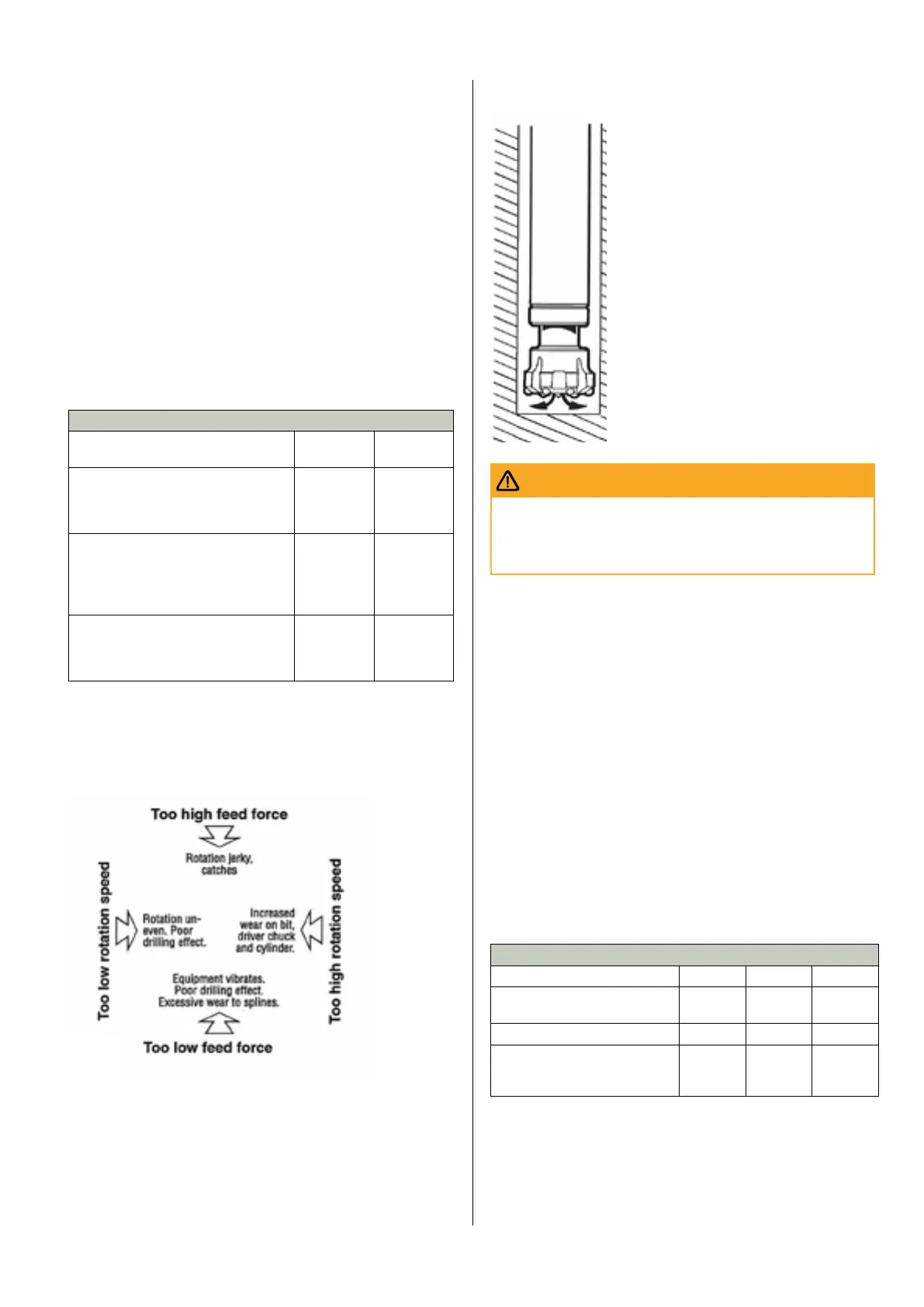

To avoid wasteful re-crushing and the risk of

jam ming, drill cuttings must be flushed out

of the drill hole at the same rate as new

cuttings are produced. It is good drilling

practice to clean out the hole at regular

intervals by means of air-blowing. This is

especially import ant in non-consolidated

formations and when there is a danger of the

hole wall collapsing. Air-blowing is done by

lifting the hammer off the bottom of the hole

(fig. a) and running the feed back and forth.

N�B� Rotation must always be to the right.

The impact mechanism stops as soon as the

hammer is lifted and the bit drops down

-

wards, which causes a considerable volume

of air to flow through the hammer and flush-

out the hole. When the hammer is lowered

back on to the bottom of the hole, the bit is

pressed back into the impact position, which

re-starts the impact mechanism.

• Always wear goggles during drilling. The backward-direct-

ed flushing air from the top sub contains drill cuttings and oil

residue which can injure the eyes.

WARNING

Extra flushing

The need for extra flushing is greater when drillingt with lowe

working pressures and in difficult drilling conditions, e.g. when

there is a high flow of water inteo the drill hole.

Extra flushing is obtained by changing the plug in the control tube

to a special "choke plug", which has an air duct passing straight to

the flushing ducts in the drill bit.

Changing the choke plug

The choke plug can be changed when the control tube has been

removed from the DTH hammer. The choke plug is then removed

and fitted as follows:

Place the control tube on a workbench wiith the collar downwards.

Knock out the plug with the aid of a mandrel.

Now turn the control tube so that the collar is uppemost. Tap in the

new plug with the aid of a mandrel. To make it easier to fit the plug

into the control tube, the guide of the plug can be smeared qwith a

soap solution or similar substance.

Air consumption

COP 32 6 bar 12 bar

With choke

plug ø 4 mm

50 l/s

120 l/s

COP 42 6 bar 10�5 bar 18 bar

With choke plug

ø 5 mm

ø 7 mm

71 l/s

85 l/s

132 l/s

149 l/s

250 l/s

280 l/s

Drilling in wet holes

The inflow of water into the drill hole is expected when drilling

water wells, but can also occur when drilling deep holes for other

purposes. Water inflow does not normally create problems for

drilling, although both “too little” and “too much” can be trouble-

some.

Loading...

Loading...