L200/L201/L100/L101 Revision A

Confidential

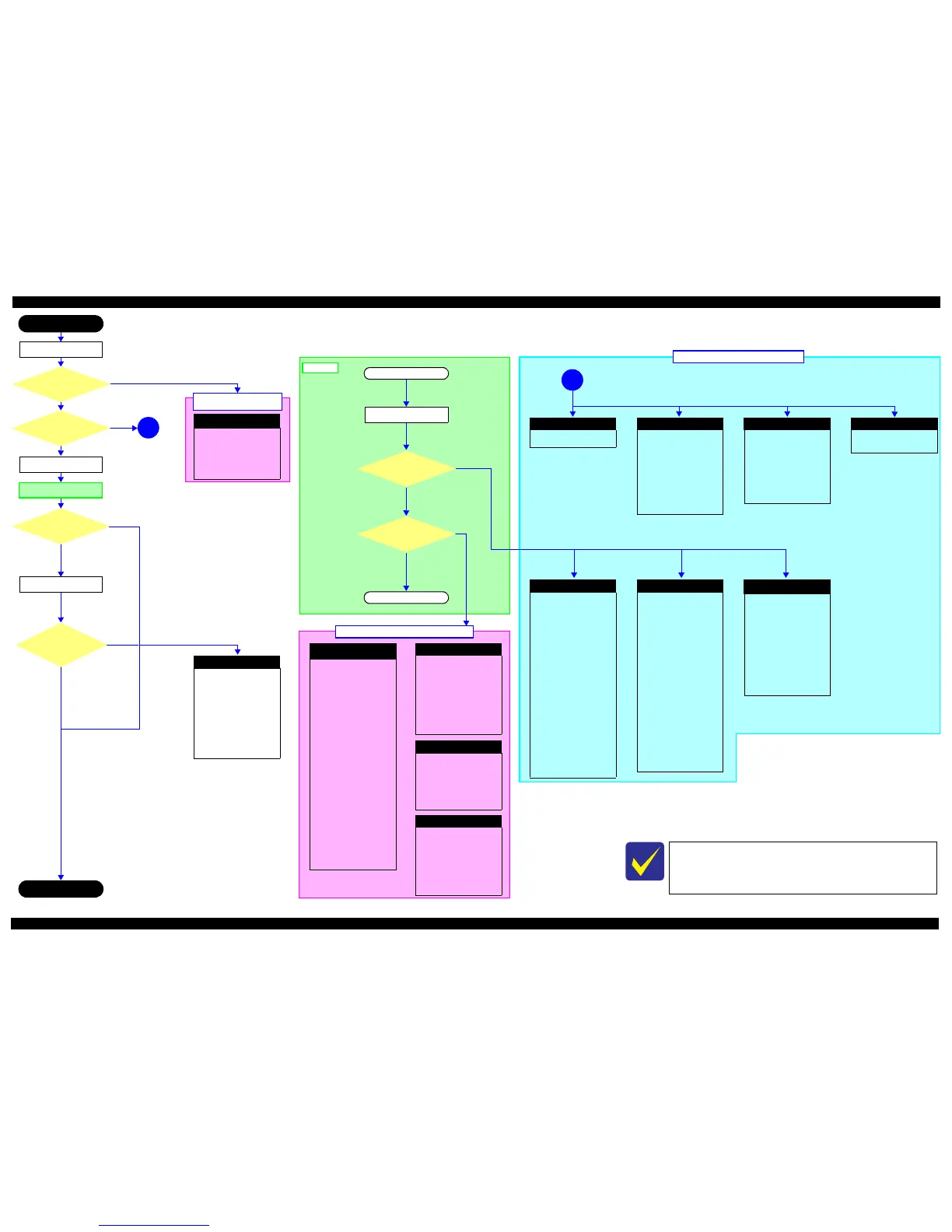

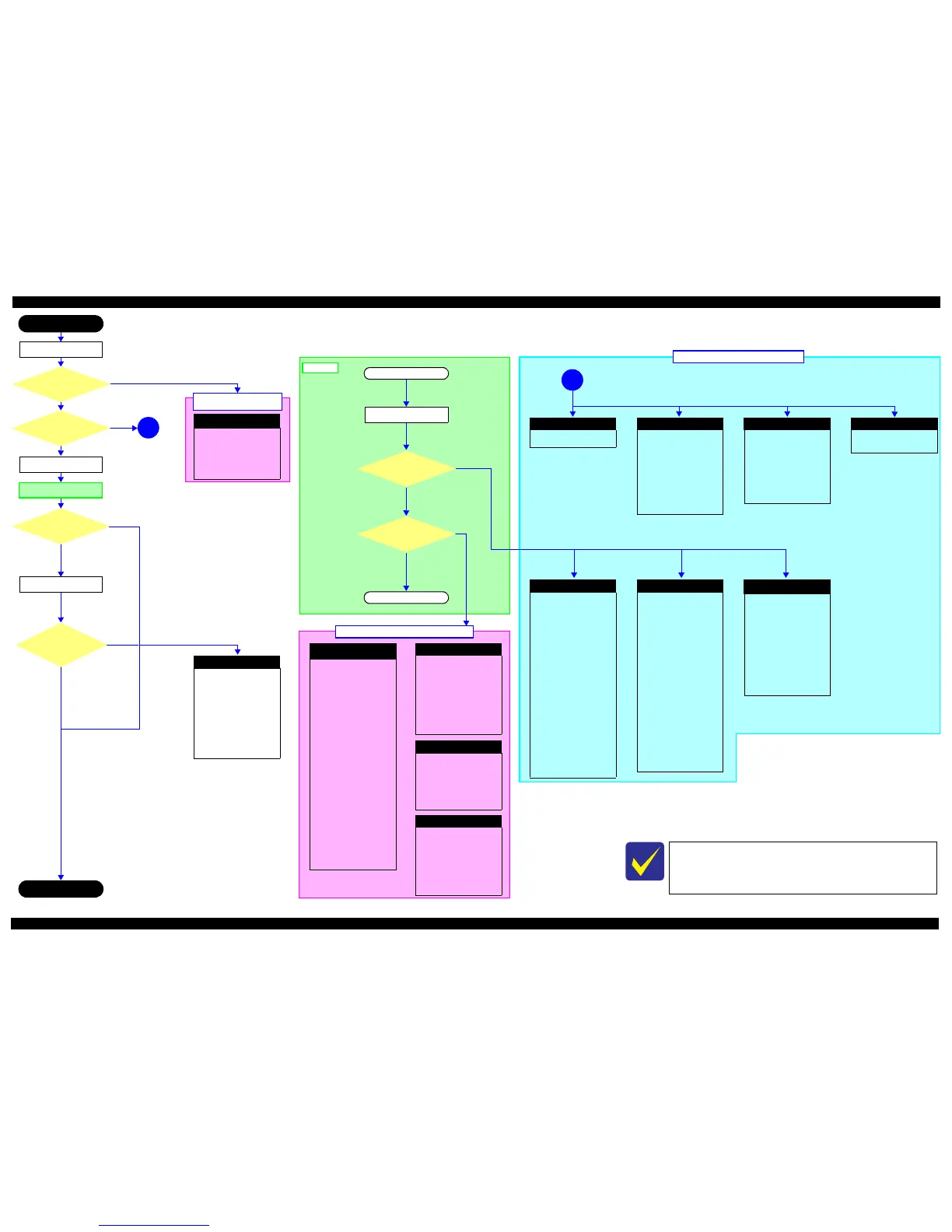

Appendix Troubleshooting Workflow 46

This flowchart is compiled based on the following contents.

Our experience regarding the quality problem.

ESK’s repair data on FY08 / FY09 models.

Printer Mechanism specification for L200/L201/L100/L101.

Fatal error

Please refer to “ 4.3.2 Fatal Error

Code (p47)”for troubleshooting.

Maintenance error

[Occurrence Condition]

This error occurs when

maintenance counter in EEPROM

exceeds the specified value.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

[Troubleshooting]

• Porous Pad replacement

• Tube Assy replacement

• Maintenance counter reset

Ink End error

[Occurrence Condition]

This error occurs when ink in Ink

Cartridge is empty.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

• Print timing

[Troubleshooting]

• Refill the ink(s)

Paper Jam error

Please refer to “ Paper Jam error”

of “Error occurs in printing

operation”.

Paper Jam error

[Occurrence Condition]

This error occurs when top/

bottom of paper is not detected by

PE Sensor in the specified steps of

paper feeding operation correctly.

[Major Occurrence Timing]

• Power-on timing

• Paper loading timing

• Paper eject timing

[Major Troubleshooting]

1 Push “Start” button to eject the

paper.

•Success

Start paper feeding operation

again if printer has print data.

•Fail

Occur paper jam error again.

2 If fail in the above 1), remove

the paper.

3 Push “Start” button again.

•Success

Start paper feeding operation

again if printer has print data.

•Fail

Occur paper jam error again.

4 If fail in the above 3), check

foreign material / part come-

off / PE Sensor Lever / Porous

Pad on Paper Guide Front /

Main board.

No Paper error

[Occurrence Condition]

This error occurs when top of

paper is not detected by PE Sensor

in the specified steps of paper

loading operation correctly.

(No paper / No loading / No

cassette / large paper skew)

[Major Occurrence Timing]

• Paper loading timing

[Major Troubleshooting]

1 Put papers in cassette and push

“Start” button.

2 If a paper stops before reaching

PE Sensor, remove it and

check the paper condition.

3 A) If no damage in the above 2),

set edge guide correctly after

putting papers in cassette and

retry.

B) If damage in the above 2),

check foreign materials /

parts come-off / parts

transformation in paper

path.

4 If not resolved by 3-A) & 3-B),

check foreign material / Part

come-off / surface condition of

LD Roller / PE Sensor Lever /

Main Board / PF Motor.

Double Feed error

*2

[Occurrence Condition]

This error occurs on the following

case.

• A paper is ejected without

printing during paper loading

operation.

• Actual paper length is longer

than theoretical one.

[Major Occurrence Timing]

• Paper loading timing

• Paper feed timing

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• Main Board replacement

No Power

*1

[Presumable Cause]

• Power Supply Board damage

• Main Board damage

[Major Troubleshooting]

• Power Supply Board

replacement

• Main Board replacement

Poor Printing

[Phenomenon]

• Poor printing quality

• Ink stain on paper

• Dot missing

• Paper eject without printing

[Presumable Cause]

• Driver / Panel mis-setting

• Contamination of CR scale

• Contamination of Printhead

cover

• Printhead damage

• Ink clogging of Printhead

• Contamination on Cap Unit /

Wiper of Ink System Assy

• Ink System Assy damage

• Float of Porous Pad on Paper

Guide Front

•Narrow PG

• PE Sensor Lever damage

• PE Sensor damage

[Major Troubleshooting]

• Driver / Panel re-setting

• CR Scale replacement

• Printhead cover cleaning

• Printhead cleaning

• Ink Cartridge replacement

• Printhead replacement

• Rubber cleaning of Cap Unit

• Ink System Assy replacement

• Porous Pad re-installation

•PG readjustment

• Printer Mechanism

replacement

• PE Sensor Lever replacement

Poor Paper Loading

[Presumable Cause]

• Use of 3rd party media

• Edge guide mis-setting

• Foreign material

• Part come-off

[Major Troubleshooting]

• Recommendation of EPSON

media

• Edge guide re-setting

• Foreign material removal

• Part re-installation

• Roller replacement

Abnormal Noise

[Presumable Cause]

• Foreign material

• Insufficient grease

•Gear damage

[Major Troubleshooting]

• Foreign material removal

• Lubrication of grease

• Gear replacement

Scanner failure

[Presumable Cause]

• Contamination of Scanner

Glass

• Contamination of Document

Pad

• CIS Unit bonding failure

• CIS Unit damage

• Scanner Motor damage

[Major Troubleshooting]

• Scanner Glass cleaning

• Document Pad cleaning

• Document Pad replacement

• CIS Unit replacement

• Scanner Motor replacement

Finish

*4

Turn on the printer

1

1

Major problem without error message

What is returned reason?

Copy an image

Flow A

Return previous flow

Is printing operation

finished without trouble?

Start

Scanner unit

failure

*3

Printer failure only

No

Yes

Yes

No

Yes

No

Yes

No

Yes

No

Start

Is printing operation

finished without error?

*1: If the printer can turn on but turns off right away, the protection circuit may cut off

the power due to an error such as a circuit failure.

*2: Only for manual duplex print

*3: Only for L200/L201.

*4: In case of “Not Trouble Found”, check fatal error code.

Major problem with error message

Major problem without

error message

Is Power-on sequence

finished without error?

Perform “Flow A”

Standby condition

Is scanning operation

finished without

trouble?

Does printer turn on the

power?

Print check pattern

Blank Printing

[Presumable Cause]

• Valve closes

• Ink tank ventilation film gets

wet

• Ink tube crumples

• Ink tube connection is

incomplete.

[Major Troubleshooting]

• Open valve

• Ink tank replacement

• Ink tube re-installation

Loading...

Loading...