# VSH400PLC090909

3. Move the body (1) so as the horizontal axis of the locating insert (2) covers

with the table top surface (5) [Fig.26]. For levelling, it is recommended to use

the straight piece of bus of length approximately 1.5 m.

4. Holding the immobilized body on the panel press the pushbutton H >0< at the

height of the counter H

5. Return to the basic screen of the panel by taking out the locating insert (2) or

the offset insert (3) [Fig.26]

6. Check whether the hole is correctly made with the proper distance from the

edge of the bus

7. If necessary, scale the system of the counter H again

8. TECHNOLOGY

8.1 DIE BLANKING

NOTES:

When punching holes in aluminium rails, lubricate the punch with oil or

kerosene each time. Recommended agent: HHS 2000 manufactured by

WÜRTH.

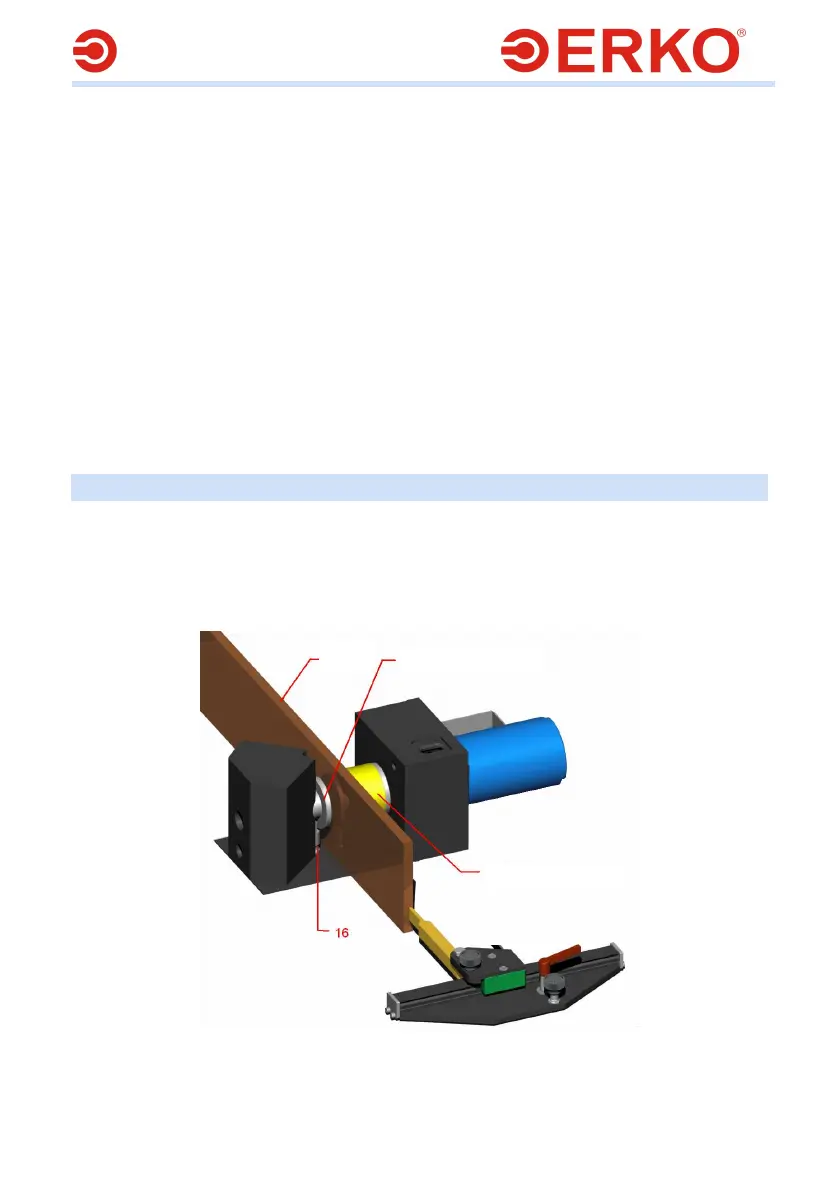

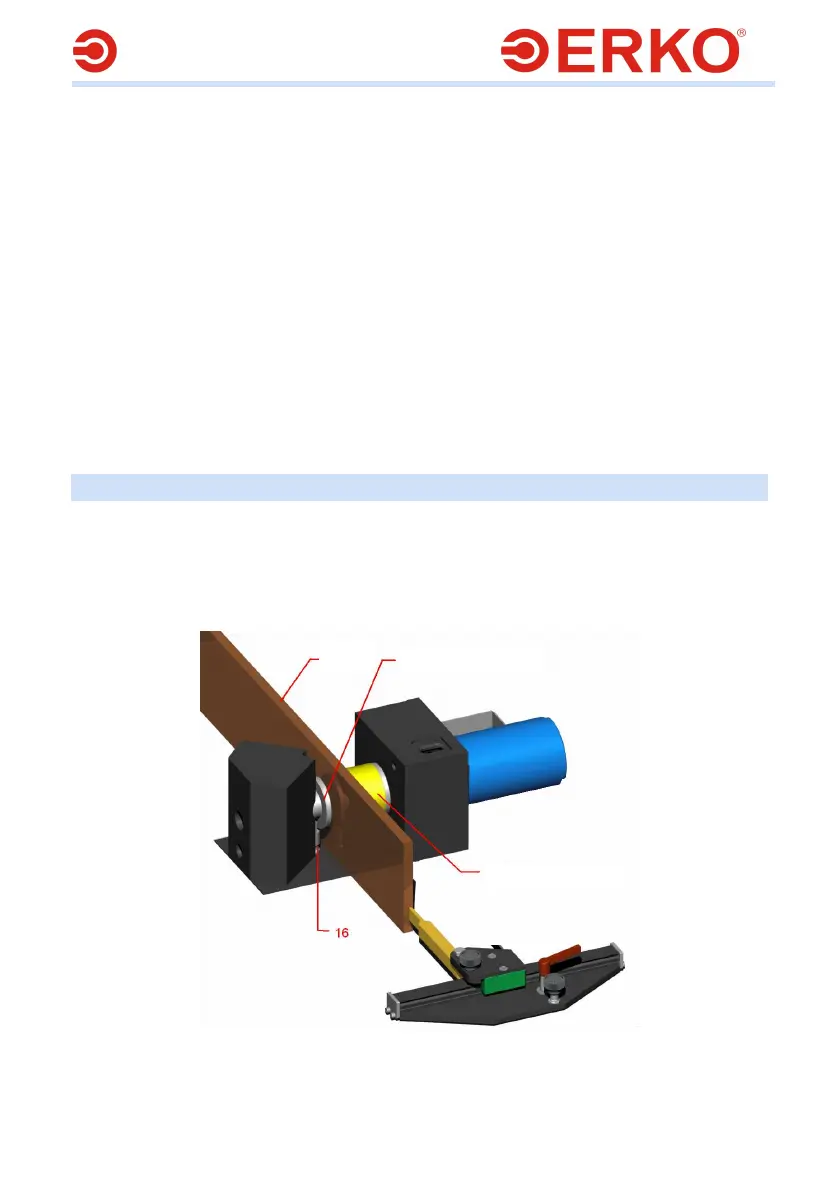

Fig.23

8.1.1 ROUND HOLES

Prepare the station as described in 6.1

busbar

setting mandrel

stamp + spring

Loading...

Loading...