- 18 -

hfa7o1ea

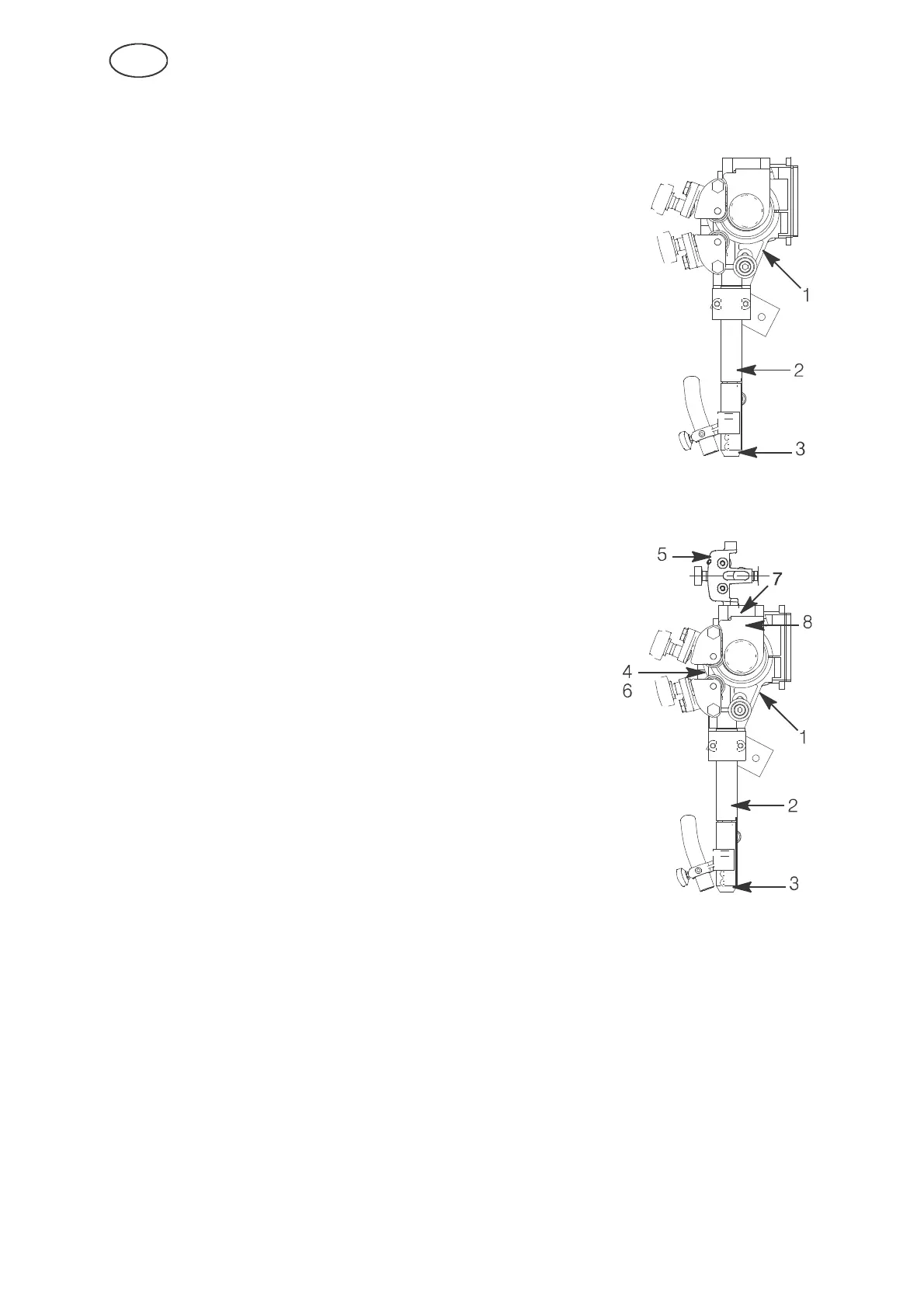

4.4 Contact Equipment for Submerged Arc Welding

4.4.1 For Single Wire 3,0 - 6,0 mm

Use automatic welding machine A6SF F1 where

the following units units are included:

Wire feed unit (1)

Connector D35 (2)

Contact jaw (3)

Ensure that good contact is achieved between the

contact jaws and the wire.

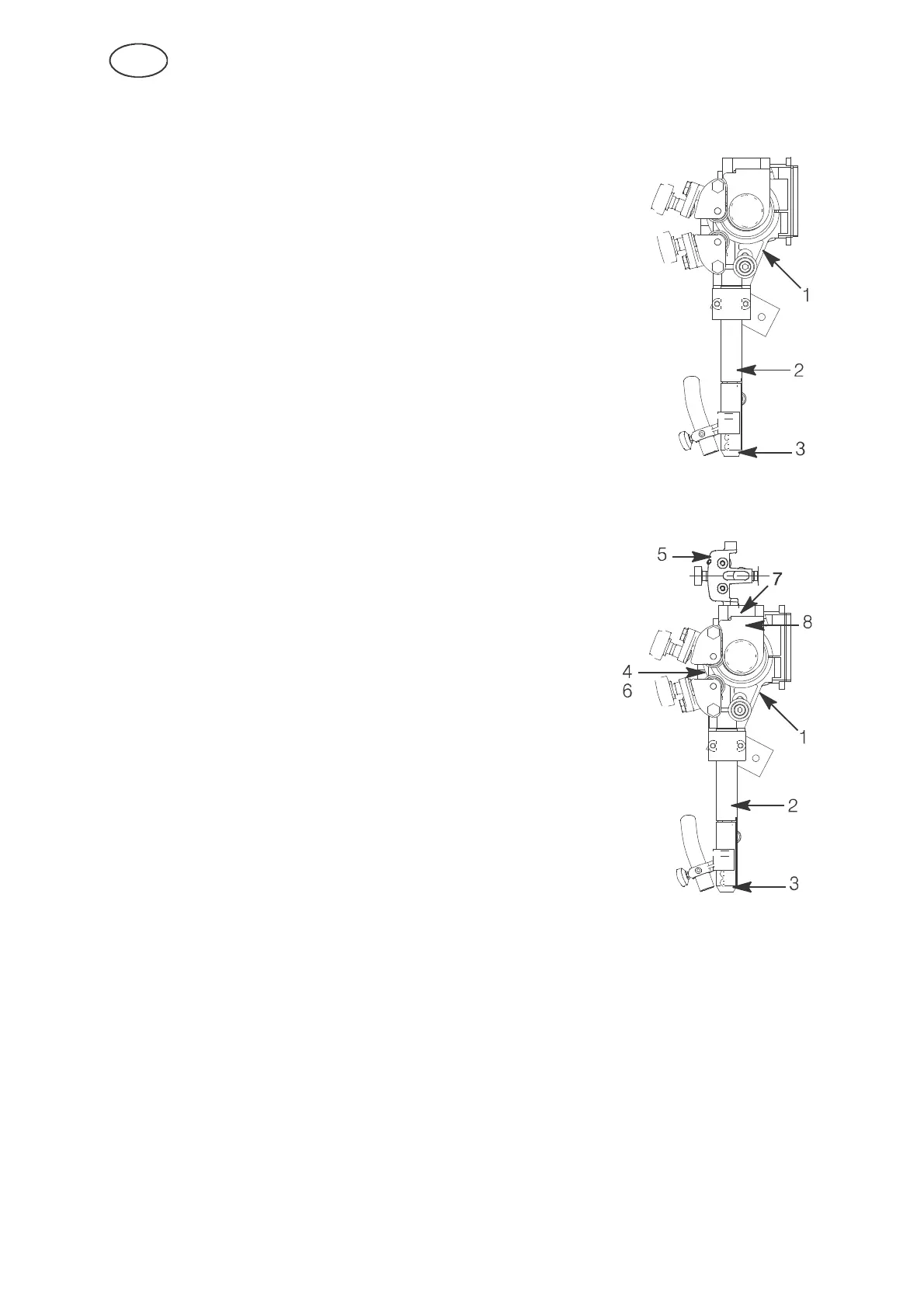

4.4.2 For Twin Wires 2 x 2,0 - 3,0 mm

Use automatic welding machine A6SF F1 Twin

where the following are included:

Wire feed unit (1)

Connector Twin D35 (2)

Contact jaw (3)

Ensure that good contact is achieved between the

contact jaws and the wire.

Guide tubes (4, 6)

Accessories:

Fine-wire straightener (5) to be fitted on top of

the clamp of the wire feed unit (1).

N.B. When mounting the fine-wire straightener,

remove the existing plate (7).

N.B. The protection plate (8) shall not be removed

Adjustment of the Wires for Twin-arc Welding:

Position the wires in the joint so as to achieve optimal weld quality by rotating the

connector. The two wires can be rotated so that they are positioned one after the

other along the line of the joint, or in any position up to 90

across the joint, i.e.

one wire on each side of the joint.

GB

Loading...

Loading...