SECTION 4 Operation

ESP 400C Plasma Power Source

ESP 400C Plasma Power SourceESP 400C Plasma Power Source

ESP 400C Plasma Power Source

4-2

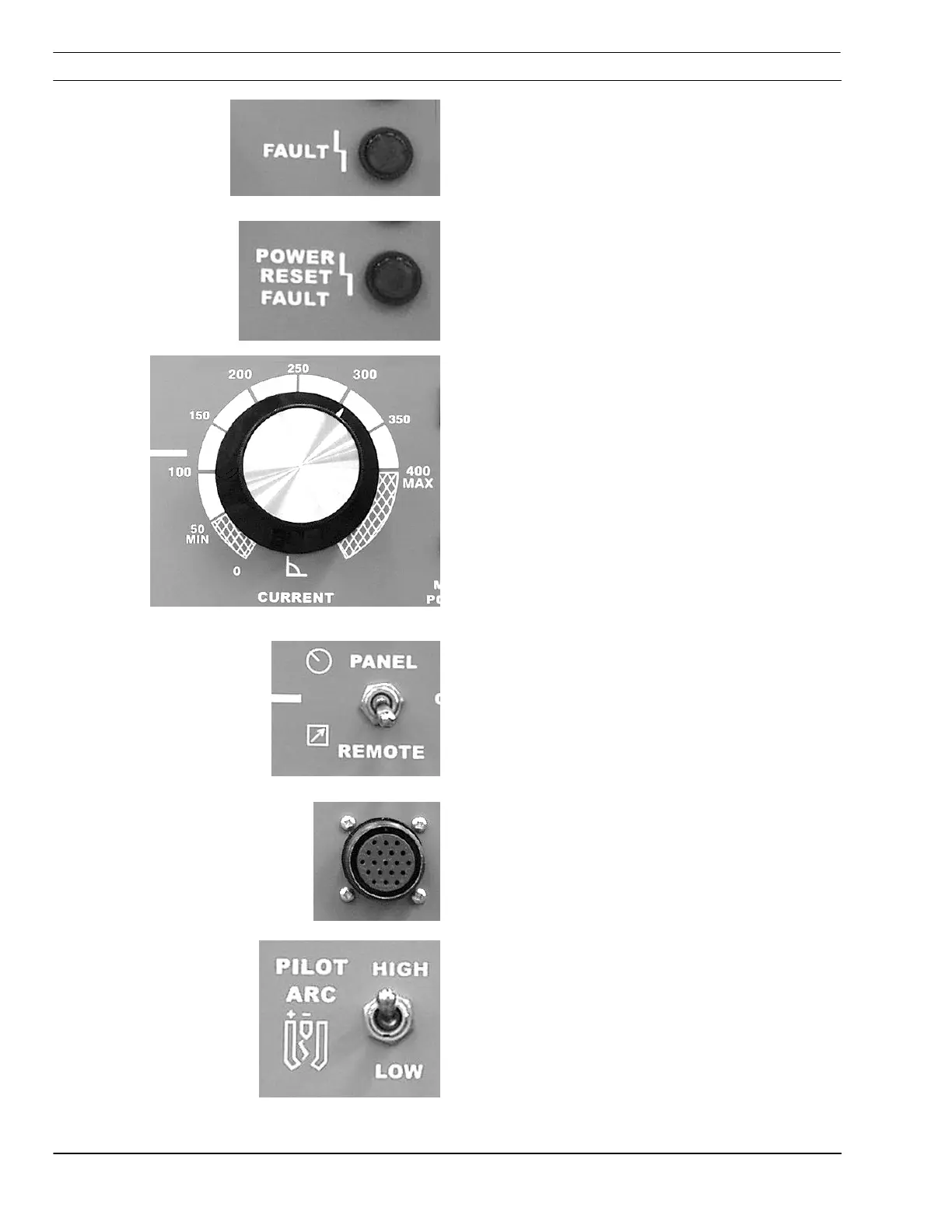

Fault

FaultFault

Fault

Indicator illuminates when there are abnormalities in

the cutting process or when the input line voltage

falls outside of the required nominal value by ±10%.

Power Reset Fault

Power Reset FaultPower Reset Fault

Power Reset Fault

Indicator illuminates when a serious fault is

detected. Input power must be disconnected for at

least 5 seconds and then reapplied.

Current Dial (Potentiometer)

Current Dial (Potentiometer)Current Dial (Potentiometer)

Current Dial (Potentiometer)

ESP-400C dial shown. ESP-400C has a range of

50 to 600 A. Used only in panel mode.

Panel Remote Switch

Panel Remote SwitchPanel Remote Switch

Panel Remote Switch

Controls the location of current control.

Place in the PANEL position for control using

the current potentiometer.

Place in REMOTE position for control from an

external signal (CNC).

Remote Connection

Remote ConnectionRemote Connection

Remote Connection

Amphenol 19 pin plug for connecting power source

to CNC.

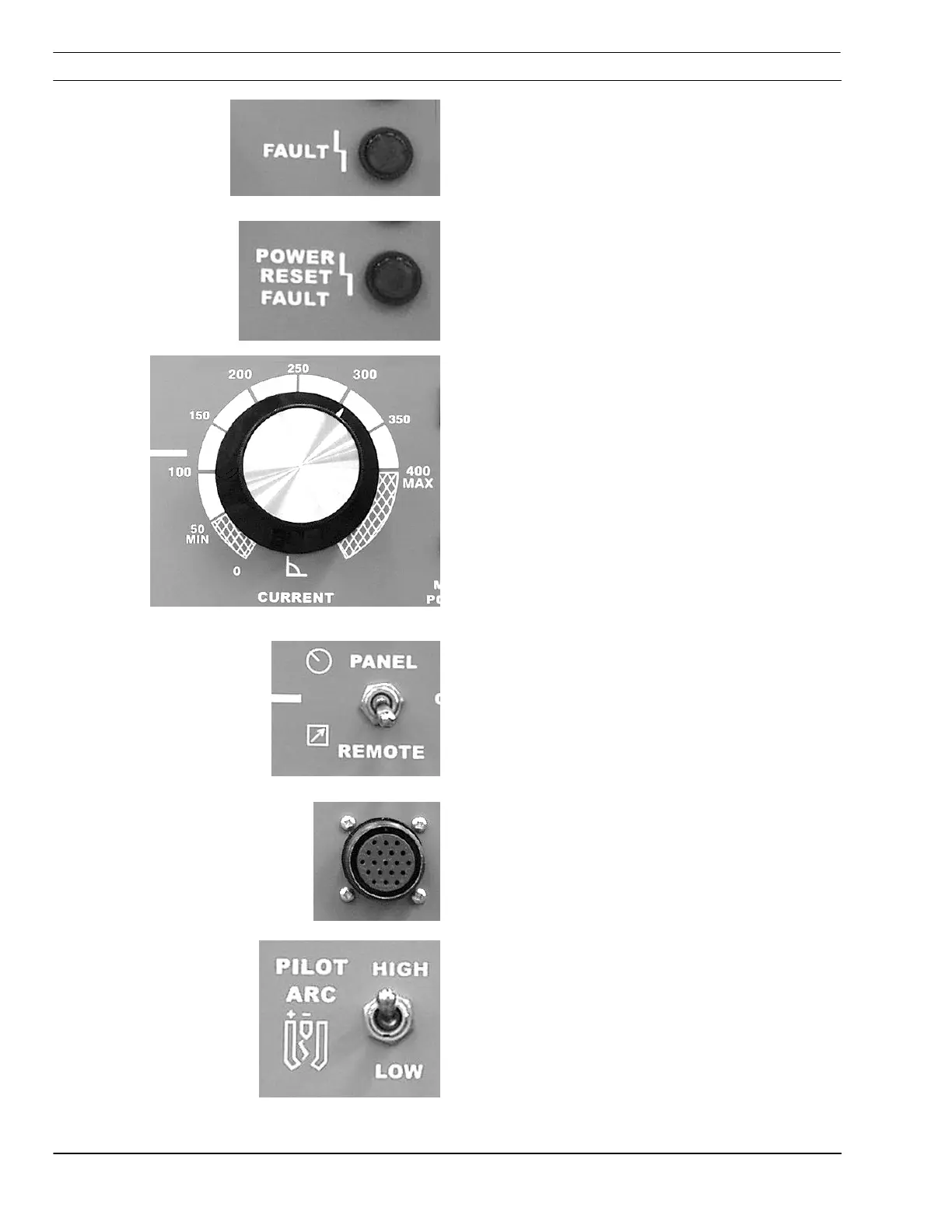

Pilot Arc HIGH/LOW Switch

Pilot Arc HIGH/LOW SwitchPilot Arc HIGH/LOW Switch

Pilot Arc HIGH/LOW Switch

Used to select amount of pilot arc current desired.

As a general rule, for 100 amperes and below, a

setting of LOW is used. This can vary depending

on gas, material and torch used. High/Low settings

are specified in cutting data included in the torch

manual.

Loading...

Loading...