6 BASIC WELDING GUIDE

0463 815 001 - 63 - © ESAB AB 2021

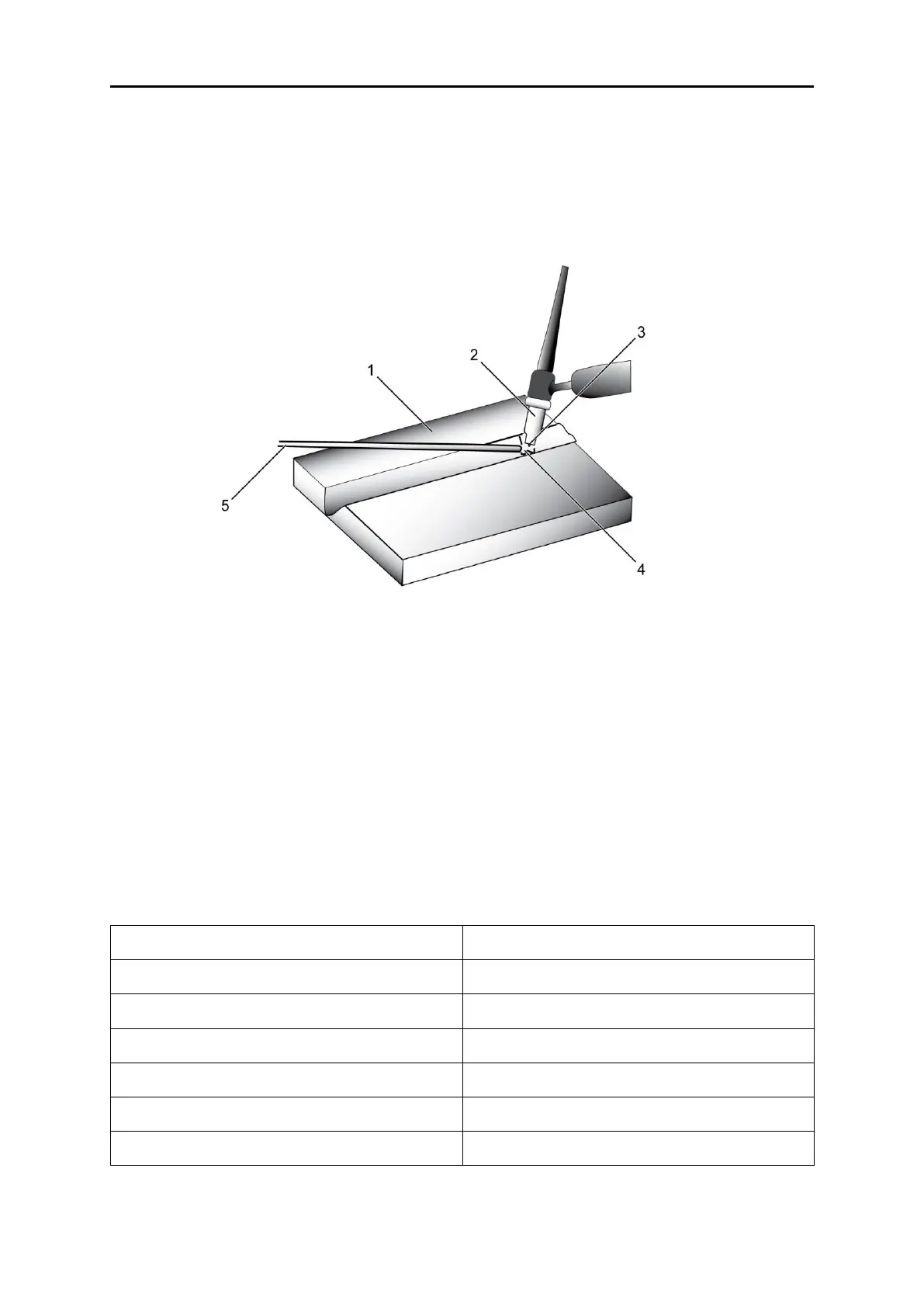

6.6 TIG (L-GTAW) basic welding technique

Gas Tungsten Arc Welding (L-GTAW) or TIG (Tungsten Inert Gas) is a welding process in which

fusion is produced by an electric arc that is established between a single tungsten (non-

consumable) electrode and the workpiece. Shielding is obtained from a welding grade shielding

gas or welding grade shielding gas mixture which is generally Argon based. A filler metal may

also be added manually in some circumstances depending on the welding application.

Figure 75: TIG (L-GTAW) welding application

1 Workpiece 4 Inert gas

2 Gas cup 5 Filler metal

3 Tungsten electrode

• Workpiece

Can be any commercial metal

• Gas cup

Either ceramic, high-impact or water cooled metal

• Tungsten electrode Non-consumable • Inert gas

Shields electrode and weld puddle

• Filler metal

Welds are made with or without addition of filler metal

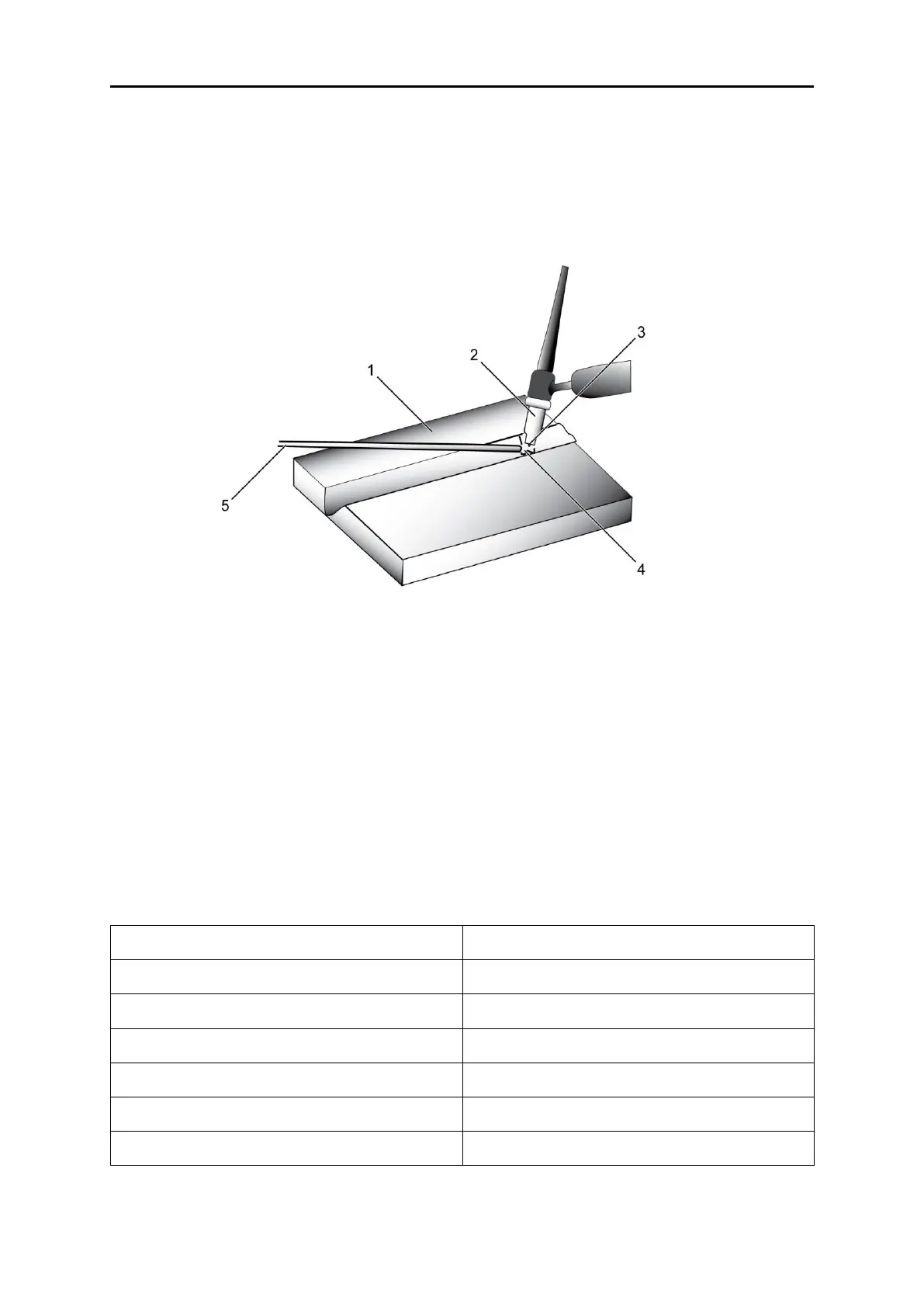

Tungsten electrode current ranges

Table 15: Current ranges for various tungsten electrode sizes

Loading...

Loading...