Do you have a question about the ESAB Fabricator 252i and is the answer not in the manual?

General safety guidelines and requirements for operating welding and plasma cutting equipment.

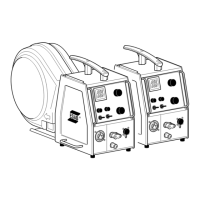

Details the ESAB Fabricator 252i as a multi-process welding power source with its capabilities and compliance.

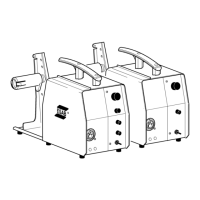

Provides safety instructions for moving the welding power source, including lifting and securing precautions.

Lists all components and accessories included with the Fabricator 252i power supply.

Explains the meaning of rated duty cycle and provides a graph illustrating operational limits based on current.

Provides detailed technical specifications for the Fabricator 252i, including dimensions, power, and output ratings.

Details the required mains supply voltage range and potential issues with incorrect voltage levels.

Addresses potential electromagnetic disturbances and user responsibilities for ensuring compatibility.

Identifies and describes the main controls, indicators, and features on the Fabricator 252i control panel.

Explains how to access and use advanced programming functions for different welding modes.

Step-by-step instructions for connecting the ESAB Fusion 250A MIG Gun to the power source.

Detailed steps for feeding welding wire through the drive roller and into the MIG Gun.

Provides instructions and safety precautions for operating the shielding gas regulator and flow meter.

Step-by-step guide for setting up the machine for MIG welding using gas-shielded wire.

Instructions for setting up the machine for LIFT TIG (GTAW) welding, including electrode sharpening.

Procedure for setting up the machine for STICK (SMAW) welding, including polarity considerations.

Explains the fundamental techniques for Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW).

Provides solutions for common MIG welding problems such as porosity and inconsistent wire feed.

Details basic techniques for Stick (SMAW) welding, including electrode selection and arc welding practice.

Explains the basic Gas Tungsten Arc Welding (GTAW) process, including electrode types and filler wire selection.

Lists error codes, their causes, and recommended remedies for power source malfunctions.

Details the schedule and requirements for routine inspection, testing, maintenance, and calibration.

Provides a routine cleaning schedule and instructions for maintaining the welding power source.

Instructions for cleaning the drive rolls to ensure proper wire feeding and prevent wear.

Lists part numbers for replacement panels and sheet metal components of the power supply.

Identifies and lists part numbers for components of the ESAB Fusion 250A MIG Gun.

Lists available optional accessories for the Fabricator 252i, including MIG guns, carts, and kits.

| Wire Size Range (MIG) | 0.023-0.045 in |

|---|---|

| Wire Size Range (Flux-Cored) | 0.030-0.045 in |

| Protection Class | IP23 |

| Input Phase | 1/3-Phase |

| Wire Feed Speed | 50-800 IPM |

| Process | MIG, Stick, TIG |

| Standards | CSA, CE |