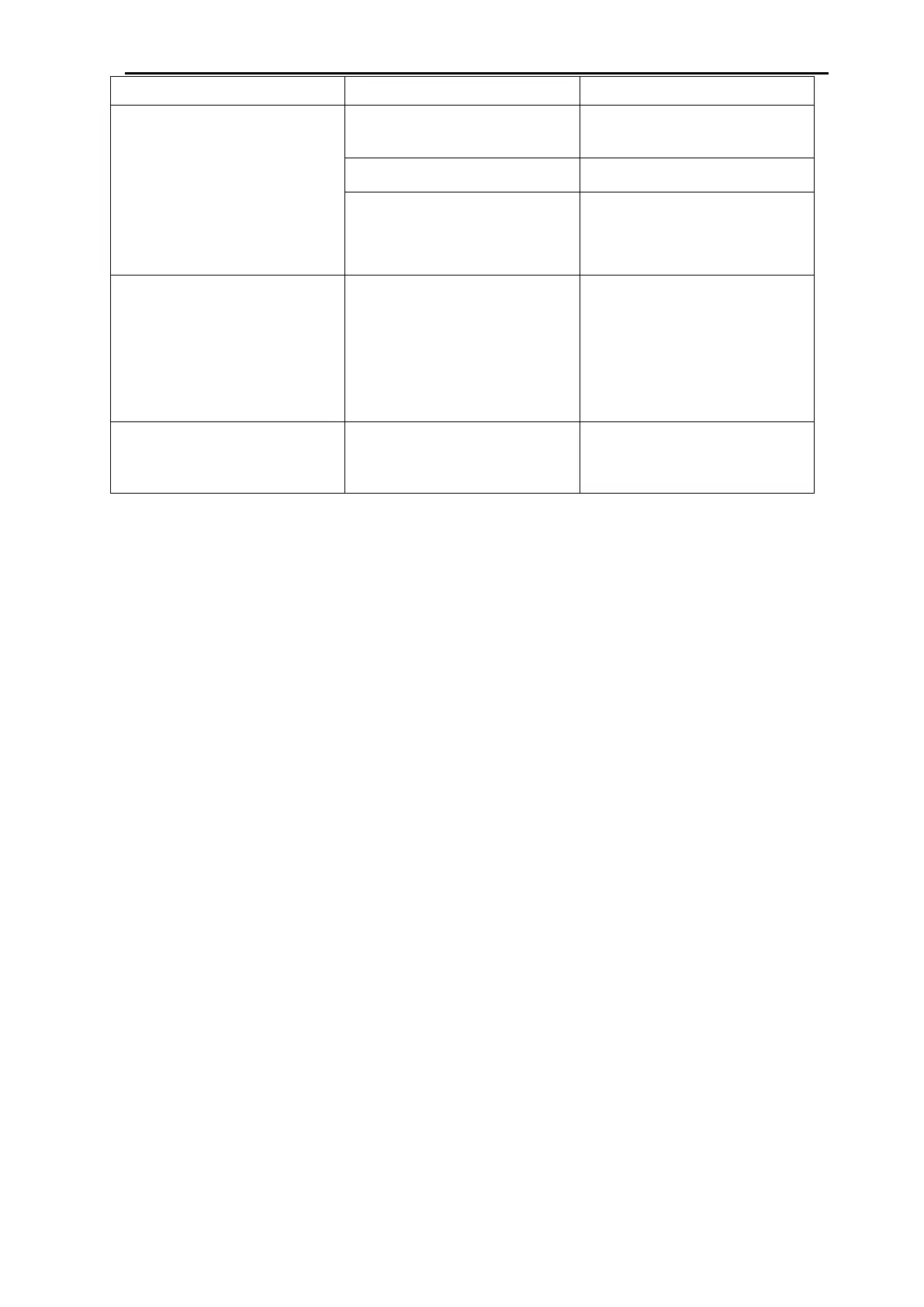

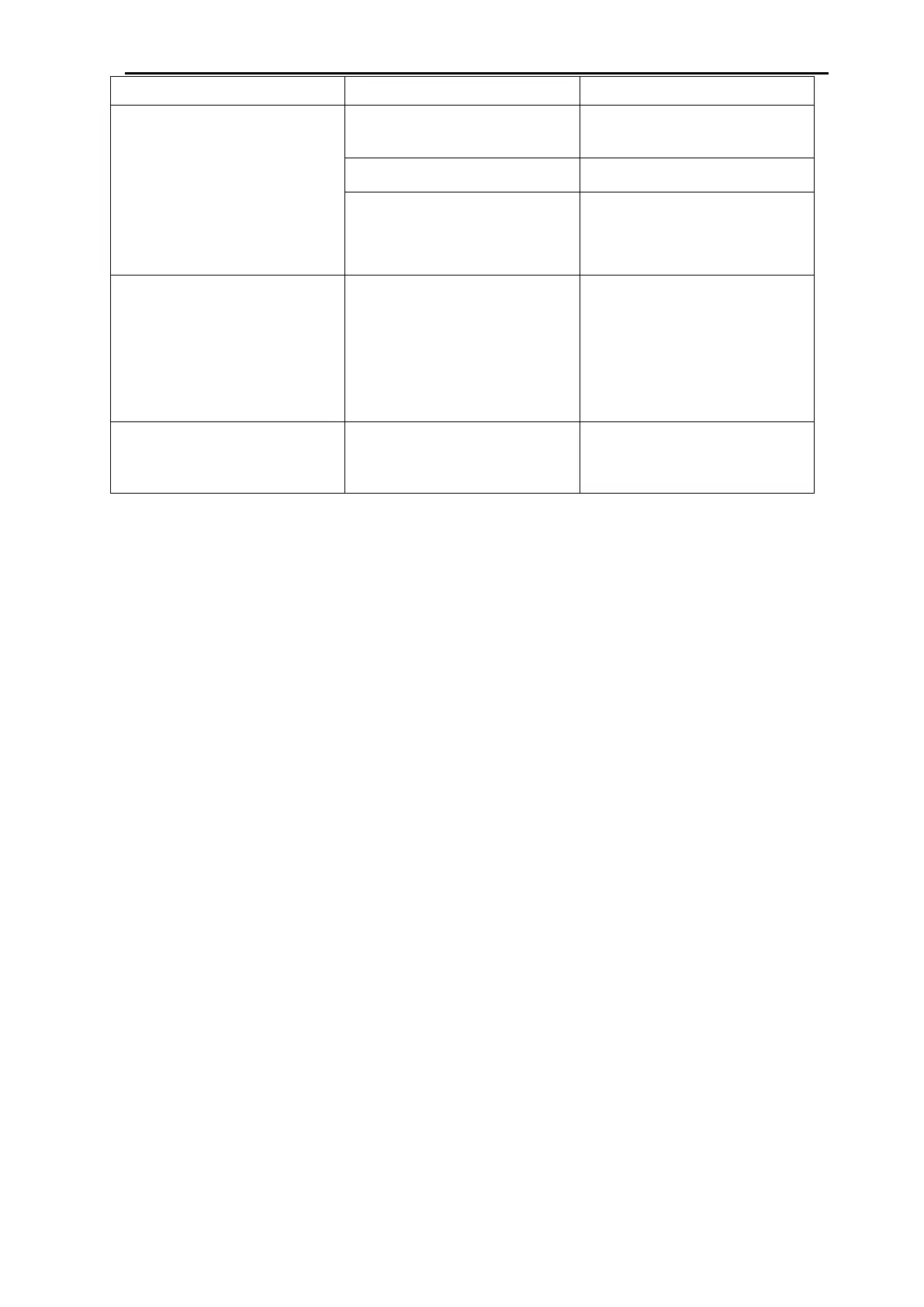

8 TROUBLESHOOTING

0463 766 001 - 73 - © ESAB AB 2021

Loose welding cable

connection.

Check all welding cable

connections.

Contact supply authority.

Have an accredited ESAB

service provider test then

replace the faulty

component.

The arc does not have a

crisp sound that short arc

exhibits when the wirefeed

speed and voltage are

adjusted correctly

The MIG gun has been

connected to the wrong

voltage polarity on the front

panel.

Connect the MIG polarity

cable to the positive (+)

welding terminal for solid

wires and gas shielded flux

cored wires. Refer to the

electrode wire manufacturer

for the correct polarity.

Poor weld result from setup

chart parameters

Contact tip has arc marks in

the bore causing excessive

drag on the wire.

Replace the contact tip with

only a genuine ESAB

velocity contact tip.

Loading...

Loading...