bt07d109

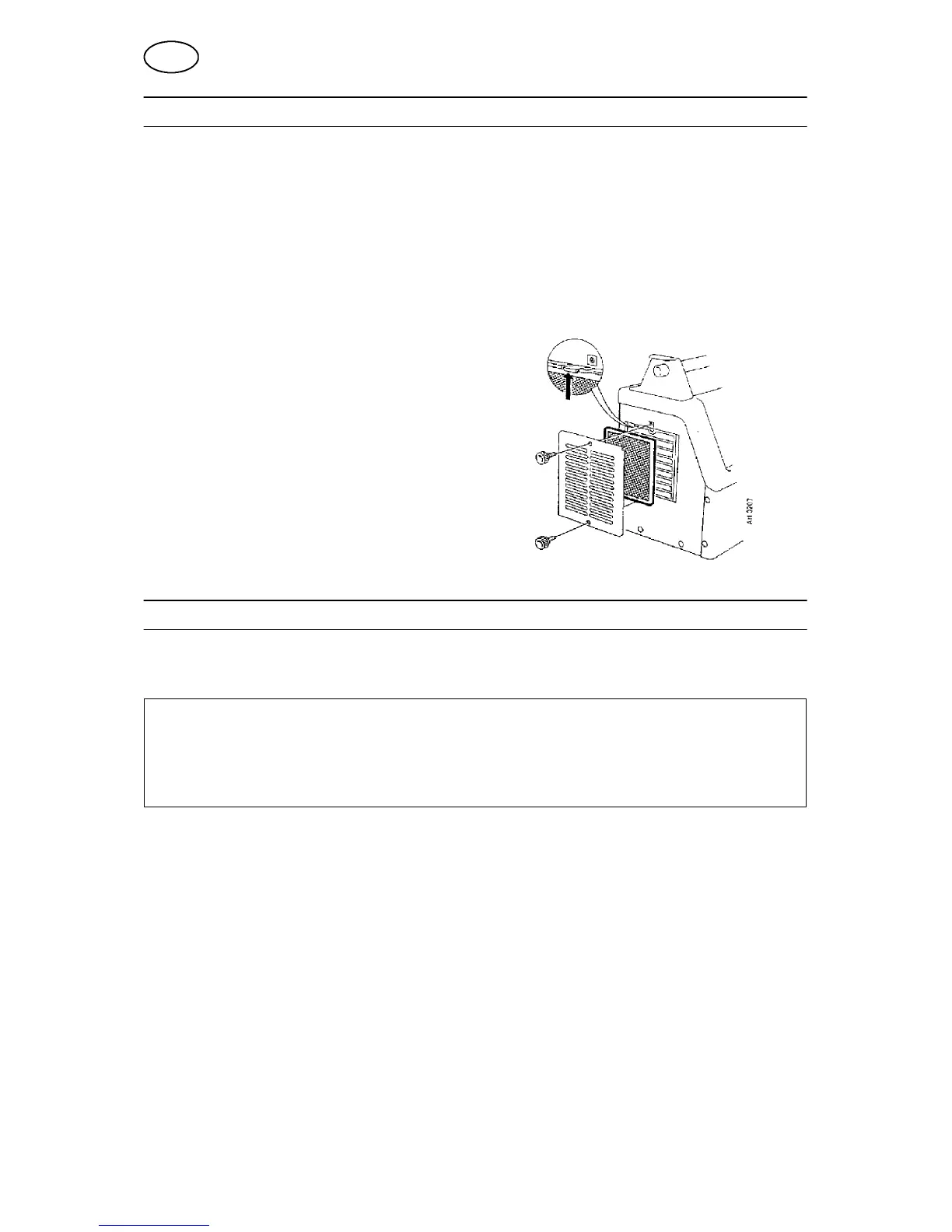

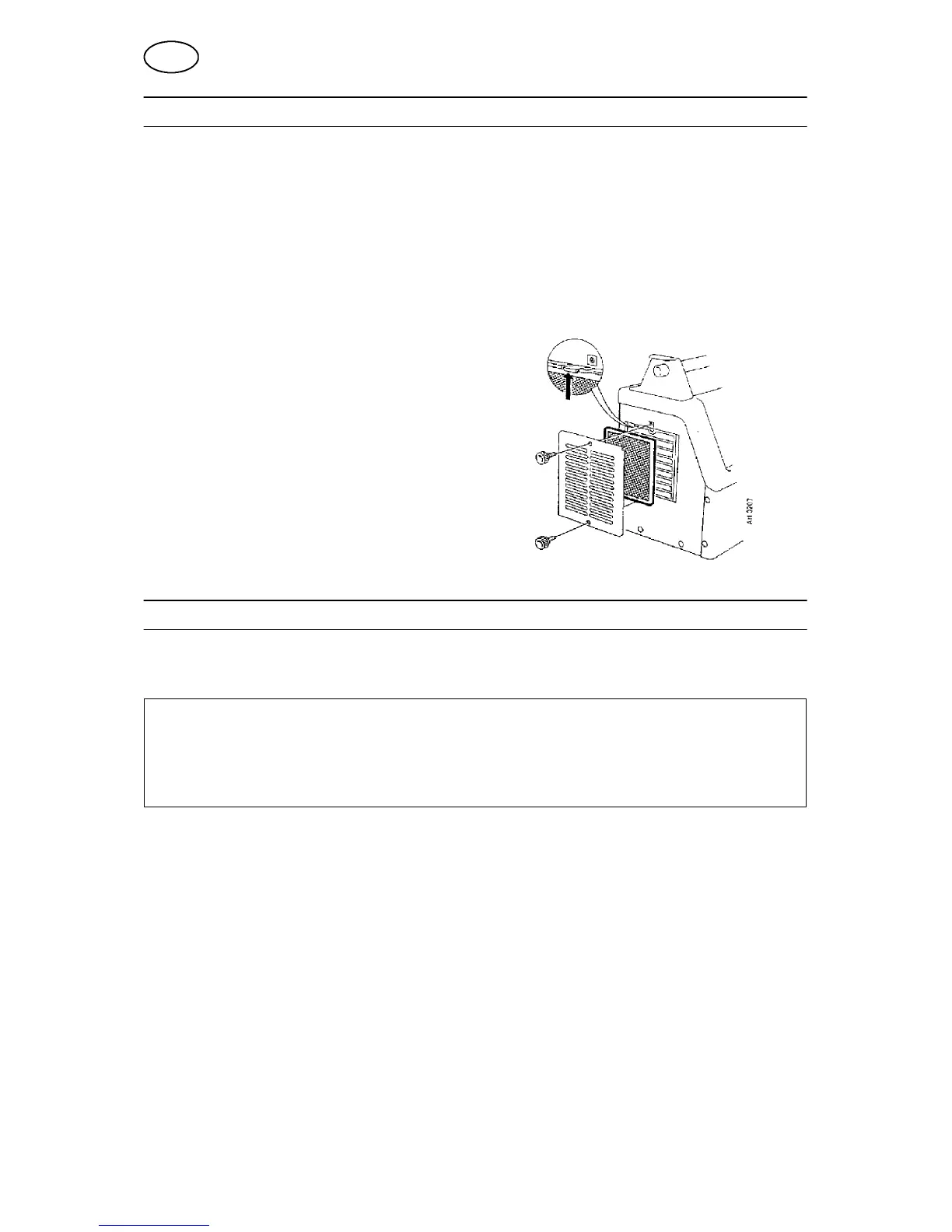

Dismantling the filter

-- 9 --

bt16d12e

7 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

Note!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any

faults.

Only those persons who have appropriate electrical knowledge (authorized

personnel) may remove the safety plates to connect or carry out service,

maintenance or repair work on welding equipment.

Generally, LTR 160/200 do not

require any maintenance. Normally,

it is sufficient to blow out the

machine using clean, compressed

air annually, and the dust filter

should be cleaned regularly.

If the machine is set up in dusty or

dirty environments the machine and

dust filter should be cleaned more

often. .

8 ORDERING OF SPARE PARTS

Repair and electrical work should be performed by an authorized ESAB serviceman.

Use only ESAB original spare and wear parts.

LTR 160, LTR 200 is designed and tested in accordance with the international and Eu-

ropean standards IEC/EN 60974--1 and EN 50199. It is the obligation of the service unit

which has carried out the service or repair work to make sure that the product still

conforms to the said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the last page of

this publication.

GB

Loading...

Loading...