16

SECTION 3 OPERATION

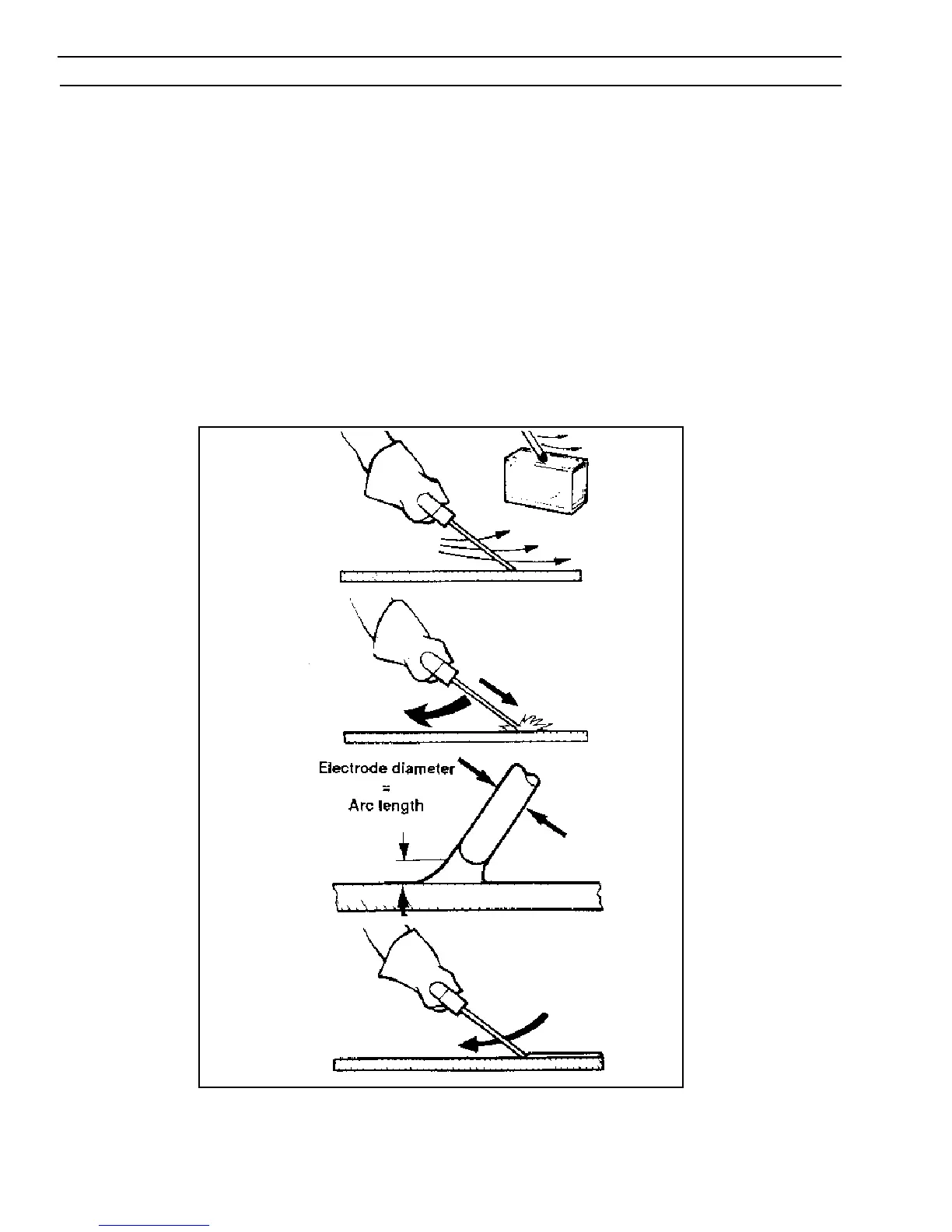

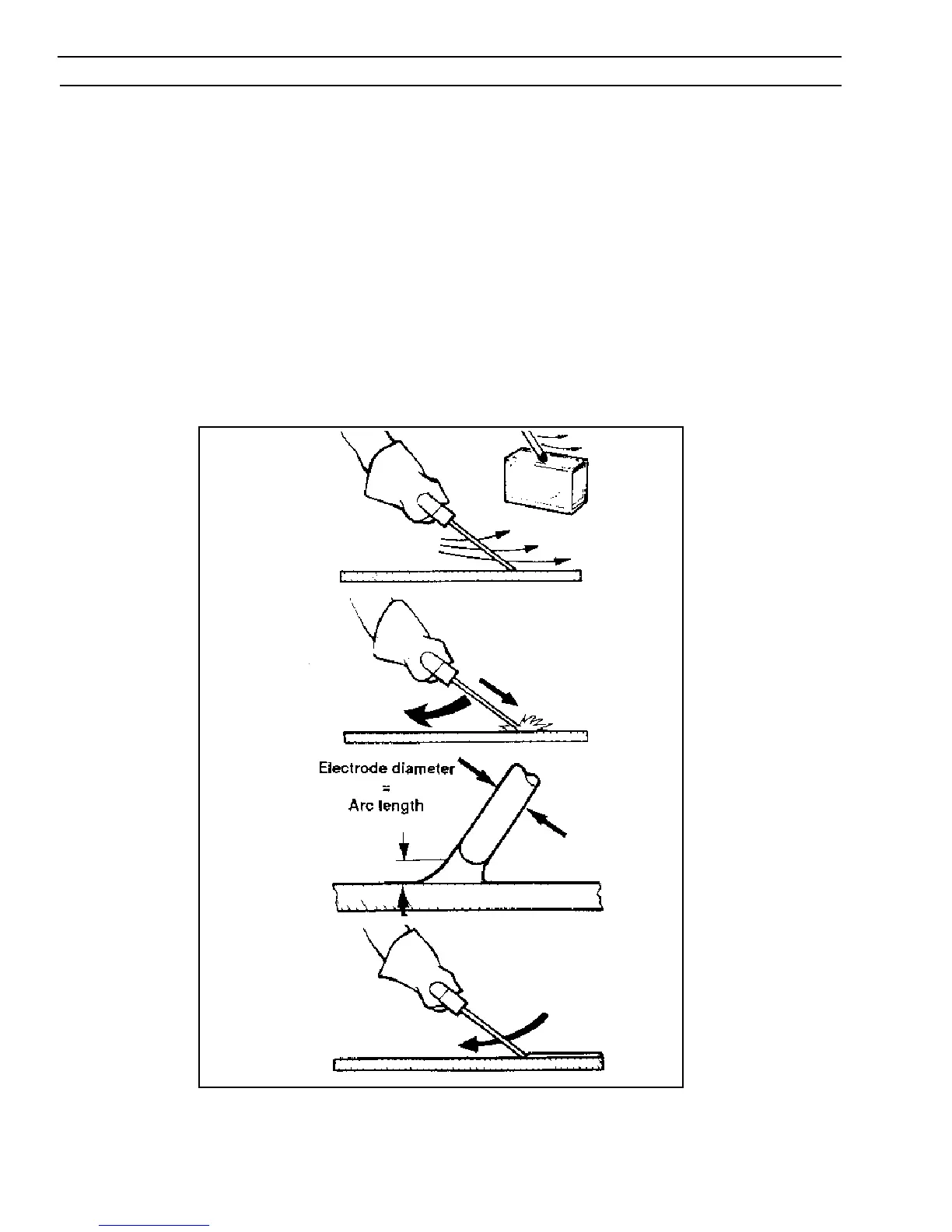

(b) Carry on scraping the electrode across the surface of the workpiece until the arc is almost continuous, then feed the electrode

into the hot pool of molten metal keeping the electrode at approximately 65-80° to the workpiece.

If the electrodes ‘freezes’, i.e. sticks to the workpiece, gently twist the electrode and pull it free. If this is not possible, switch off

the supply, release the electrode from the holder, and cut the electrode free with a chisel. Freezing will occur if heavy contact

is made with the workpiece at too low a current setting.

(c) Once the arc is successfully struck adjust the arc length to about the size of the electrode diameter.

(d) The correct length of arc, (size of weld ‘bead’) is acquired by feeding the electrode backwards and downwards into the weld.

This combination of backward and downwards movement requires a little skill which will be acquired after a few practice welds.

11. Allow the weld to cool.

Figure 3.2

Loading...

Loading...