10

1 Short contact tips are generally recommended to give proper wire stick out for flux cored wire welding.

2 Medium contact tips are generally recommended to give proper wire stick out for spray transfer Mig welding.

3 Long contact tips are generally recommended to give good visibility and proper wire stick out for dip transferring welding.

* The use of Heavy Duty tips & tubes and Extra Heavy Duty threaded nozzles extends the rating of the MT-400 to 500 amps @ 60% duty cycle

in CO

2

.

+ Use with Nozzle Adaptor (999452)

² Use with Nozzle Adaptor (948793) and Extra Heavy Duty Adaptor (17318)

u New ID for improved arc performance on steel/flux cored wire.

Notched for improved arc starting and increased tip life.

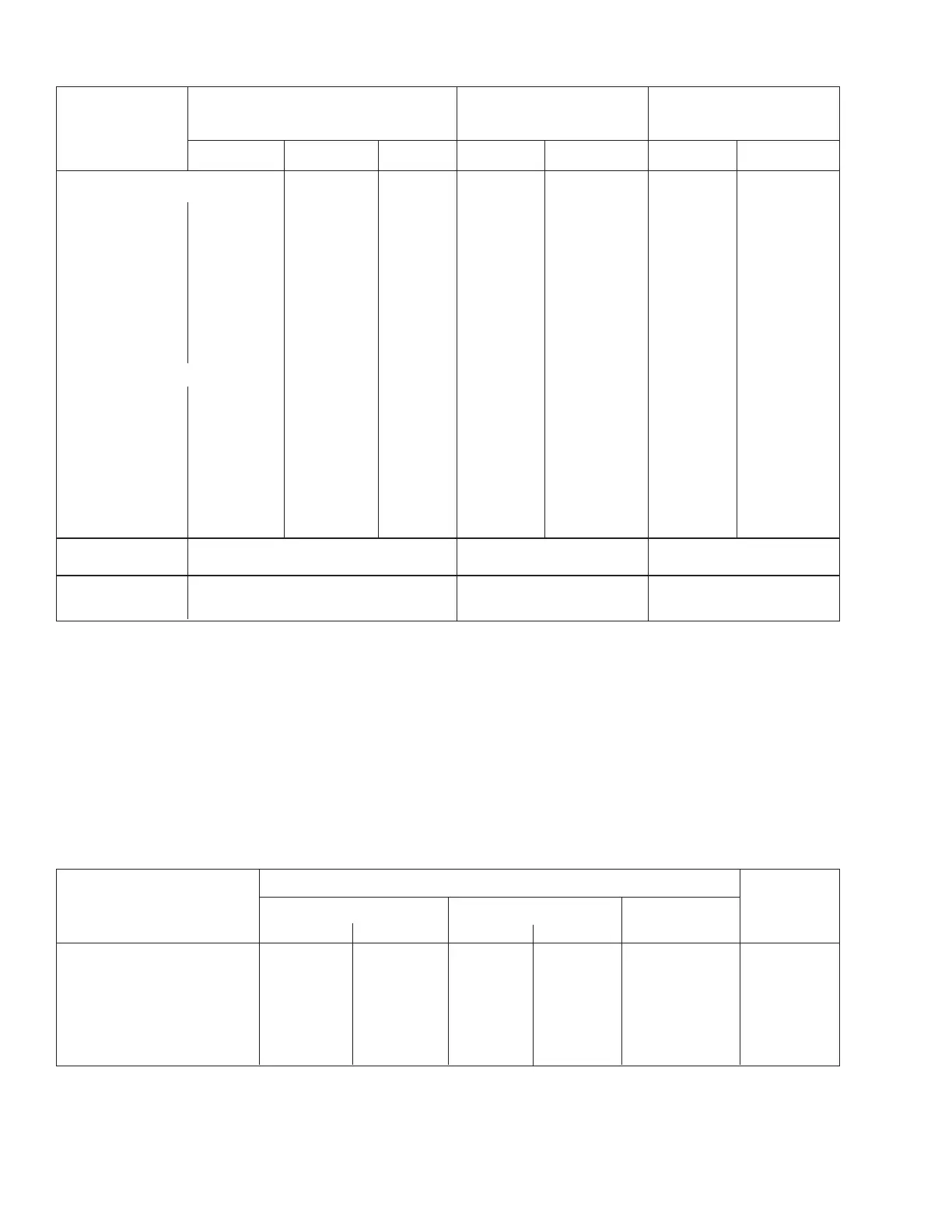

Table 1.4.1 Recommended Contact Tips, Tubes and Adaptors

Standard Duty Heavy Duty* Heavy Duty*

Wire Contact Tips Contact Tips Contact Tubes

Sizes & Type Short

1

Medium

2

Long

3

Short

1

Medium

2

Short

1

Medium

2

For Hard and Cored Wires

.023 (.6mm) - 20543 999742 - - - -

.030 (.8mm) - 20544 996994 - - - -

.035 (.9mm) - 996995 996996 - - - 17163

.040 (1.0mm) - 37287 37288 - - - -

.045 (1.2mm) 999578u 37290u 996998u - 37286u - 37292u

.052 (1.4mm) 948340u 2075349u - - 17778u - 17155u

1/16 (1.6mm) 948341u 37289u - - 37291u - 17157u

5/64 (2.0mm) - 2075230u - 948832u - 17159u -

3/32 (2.4mm) - - - 948833u - 17161u -

For Soft (Aluminum) Wires

.023 (.6mm) - 20543 999742 - - - -

.030 (.8mm) - 20544 996994 - - - -

.030 (.8mm) - 36884 --- - -

.035 (.9mm) - 996995 996996 - - - -

.035 (.9mm) - 36885 --- - -

.040 (1.0mm) - 37287 37288 - - - -

3/64 (1.2mm) - 996999 - - 17765 17164

3/64 (1.2mm) - 36886 --- - -

1/16 (1.6mm) - 996997 - - 948835 - -

Tip Adaptor for 17983 (all diameters)+ 17984 (all diameters)+ Not Available

Slide-On Nozzles

Tip Adaptor for 948785 (all diameters)² 17766 (.045"-1/16")² Collet Body 17136

Threaded Nozzles 948786 (5/64"-3/32")² Collet 17135²

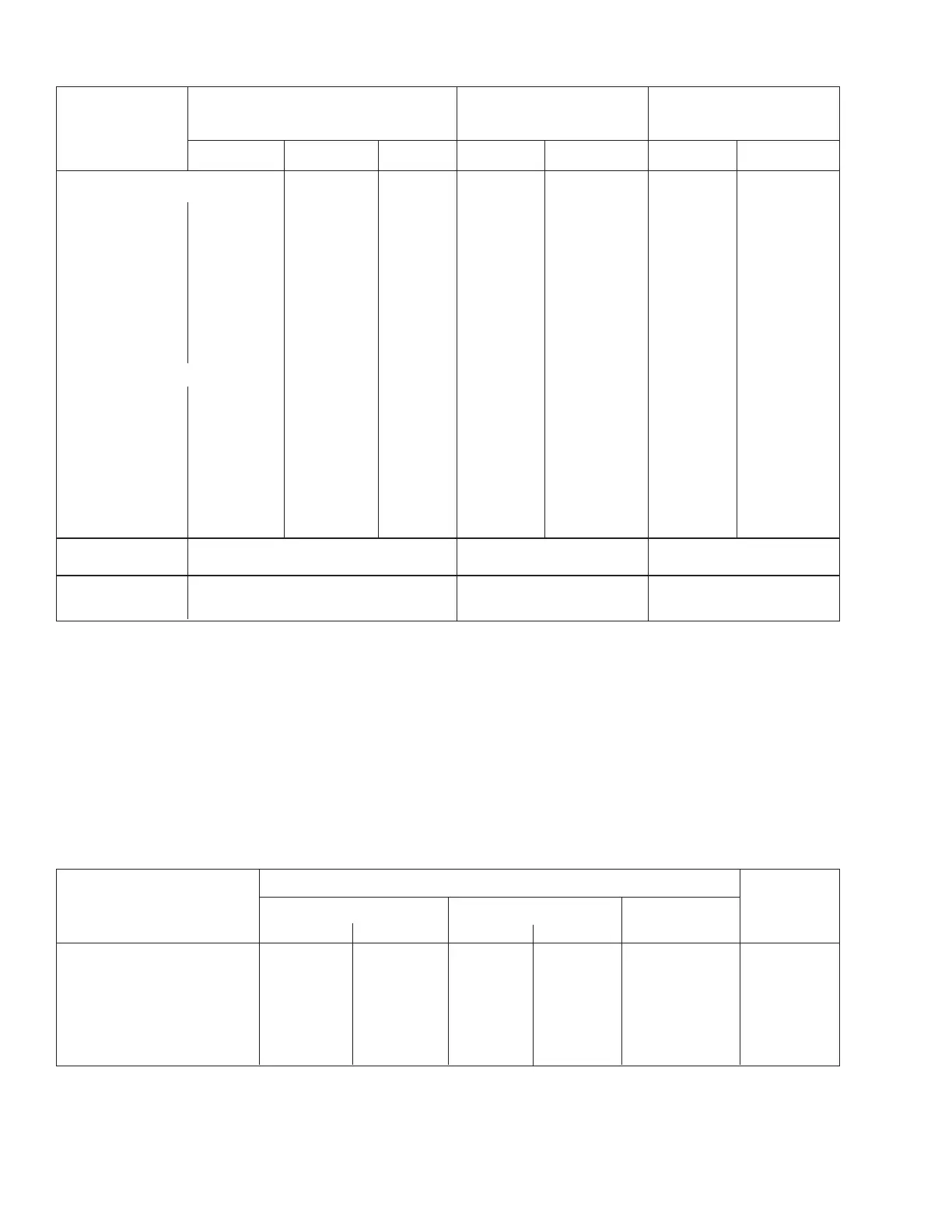

TABLE 1.4.2 Recommended Nozzles Accessories

Nozzle Slide-On, Self-Insulated* Threaded+

Standard Duty Heavy Duty Extra Heavy Extra Heavy

Description I.D. Standard Long-Lifeu Standard Long-Lifeu duty (Brass) Duty

#6 Tapered 3/8 998895 998895XL - - - -

#8 1/2 998893 998893XL 999471 999471XL - 948767

#10 5/8 998894 998894XL 999472 999472XL - 948768

#12 3/4 - - 999473 - 17350 948769

#12 Spot 3/4 17316§ - 999625 - - -

#16 Spot 1 - - - - - 999900

* Slide-on, Self-Insulated Nozzles require Adaptor 999452.

+ Threaded Nozzles require Extra Heavy Duty Adaptor 17318 and Nozzle Adaptor 948793.

§ Requires 17293 Tip Adaptor (replaces standard tip adaptor) and 17321 Nozzle Insulator.

u Long-life nozzles are coated to reduce weld spatter adherence and extend life on nozzle.

Loading...

Loading...