11

III. OPERATION

3.1 OPERATING SAFETY PRECAUTIONS

Comply with all ventilation, fire and other safety require-

ments for arc welding as established in the SAFETY

Section at the front of this manual.

Comply, also, with the following precautions:

a. Whenever welding above 250 amps, a No. 14 fil-

ter lens should be worn on your protective helmet.

Up to 250 amps, No. 11 or 12 filter lens is recom-

mended.

b. The radiant energy of the arc can decompose chlo-

rinated solvent vapors, such as trichloroethylene

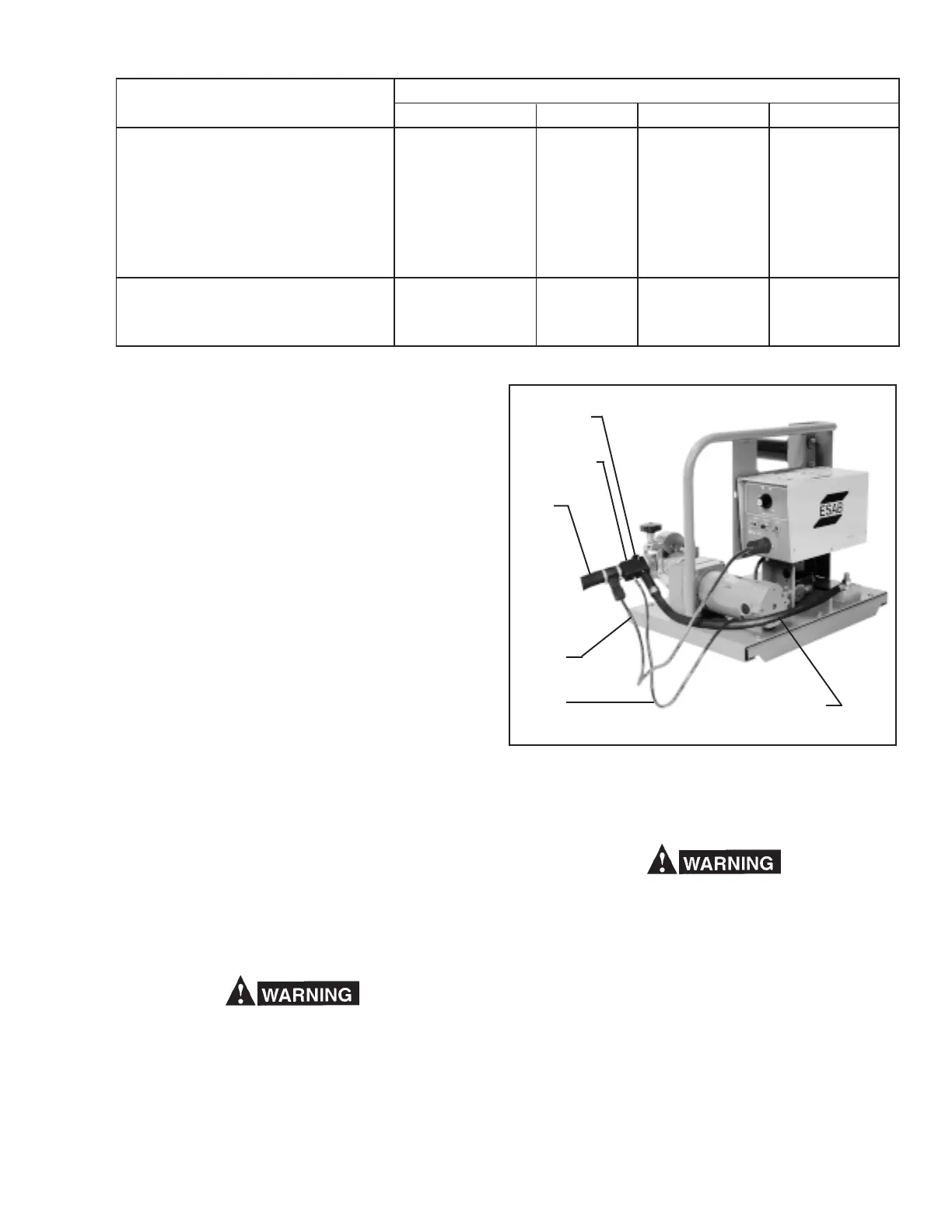

1. Install the proper feed roll (see Table 1.3) to the

wire feeder. Refer to the wire feeder booklet for

installation and adjustment details.

2. Connect the proper wire outlet guide (see Table

1.3) to the wire feeder connector assembly as

shown in figure 1.3.

3. Secure the outlet guide into the front clamp of the

accessory support assembly on the wire feeder

(refer to wire feeder instruction booklet).

4. Connect the power cable, gas hose, and switch

cord to the wire feeder (see Fig. 2.1)

5. Remove retaining pin on wire feeder connector;

insert torch inlet fitting fully; and then reinsert re-

taining pin to lock fitting in place. Be sure retaining

pin is completely pushed in before feeding the wire.

6. Use the inching switch on the wire feeder to inch

the wire through the torch.

7. The torch is now ready to operate. Refer to your

wire feeder instruction booklet for operating de-

tails.

The MT-200 or MT-400 torch is supplied with liner

and contact tip for a particular wire size and No. 8,

10 or 12 standard-duty nozzle installed. If desiring

to change these components for another wire size

as given in Table 1.4.1 through 1.4.3, refer to the

Maintenance Section for instructions.

The MT-200 is rated to operate up to 300 amps

using CO

2

; 200 amps using mixed gases (60% duty

cycle).

The MT-400 is rated to operate up to 400 amps us-

ing CO

2

; 250 amps using mixed gases (60% duty

cycle).

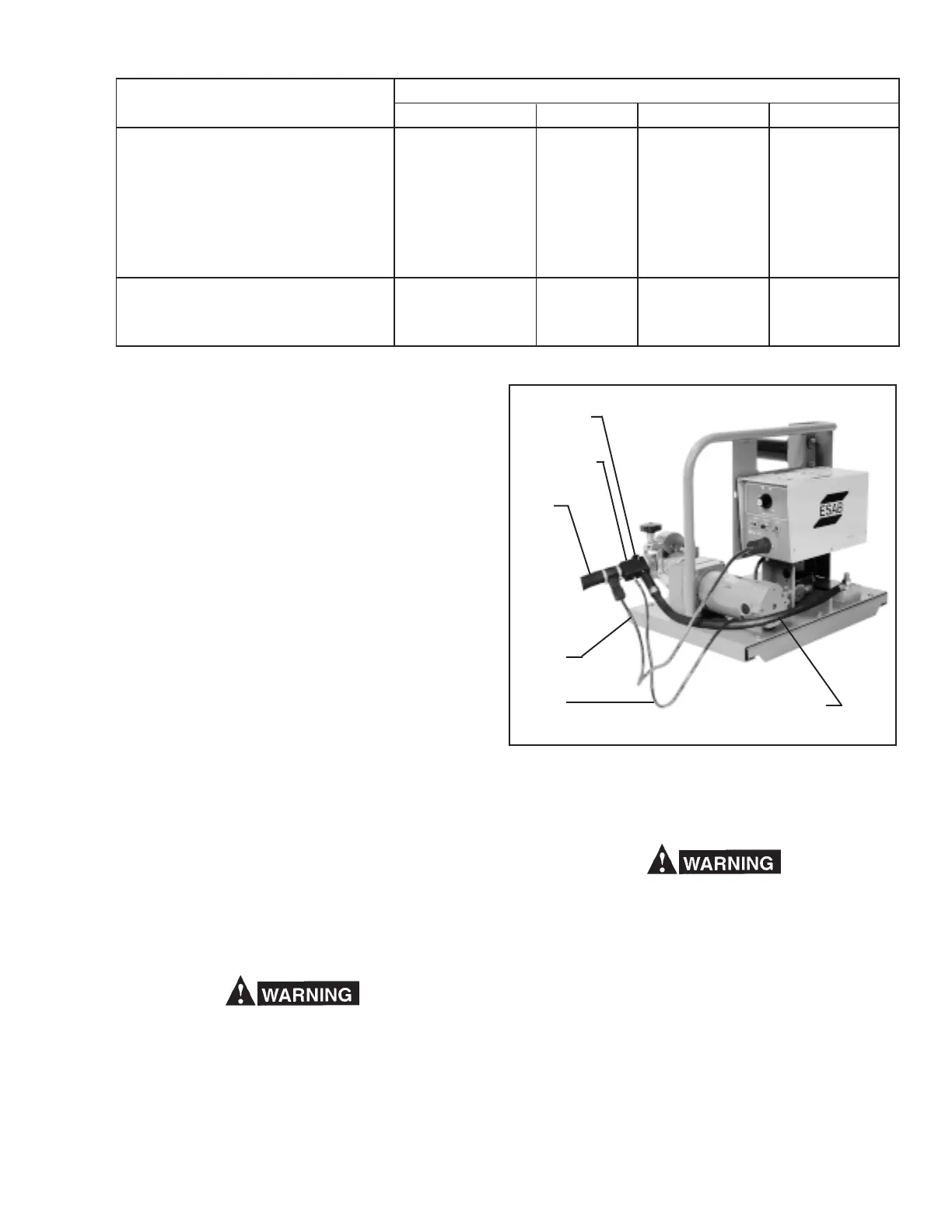

Wire Liner

Size & Type 10' 12' 15' 25'

Hard Wires & Cored Wires

.023" (.6mm) 999743* 34929* - -

.030" (.8mm) 948850 17717 - -

.035" (.9mm) 2075237 17718 2075238 18235

.045" (1.2mm) 2075237 17718 2075238 18235

.052" (1.4mm) 2075239 17719 2075240 18236

1/16" (1.6mm) 2075239 17719 2085240 18236

5/64" (2.0mm) 2075245 17720 2075246 -

3/32" (2.4mm) 2075245+ 17720 2075246 -

Soft Wires (aluminum)

.035" (.9mm) 948862 33931 - -

3/64" (1.2mm) 948863 34932 - -

1/16" (1.6mm) 19065** - - -

TABLE 1.4.3 Recommended Liners Accessories

* Requires support liner for .023" wire. Order P/N 999797 for 10 ft. or P/N 34930 for 12 ft.

** Requires Support Liner, P/N 34930.

+ 45° curved wire guide (P/N 18243) recommended for 3/32" wire.

Figure 2.1 - MT-200 or MT-400 Torch and Wire Feed Connector Shown

Attached to MIG-35 Wire Feeder

RETAINING

PIN

WIRE FEEDER

CONNECTOR

MT-200 OR MT-400

TORCH

SWITCH

CORD

(24" lg.)

GAS HOSE

(24" lg.)

POWER CABLE (24" lg.)

(Part of Wire Feeder

Connector Assembly)

Loading...

Loading...