9

1.4 TORCH ACCESSORY GUIDE & SELECTION -

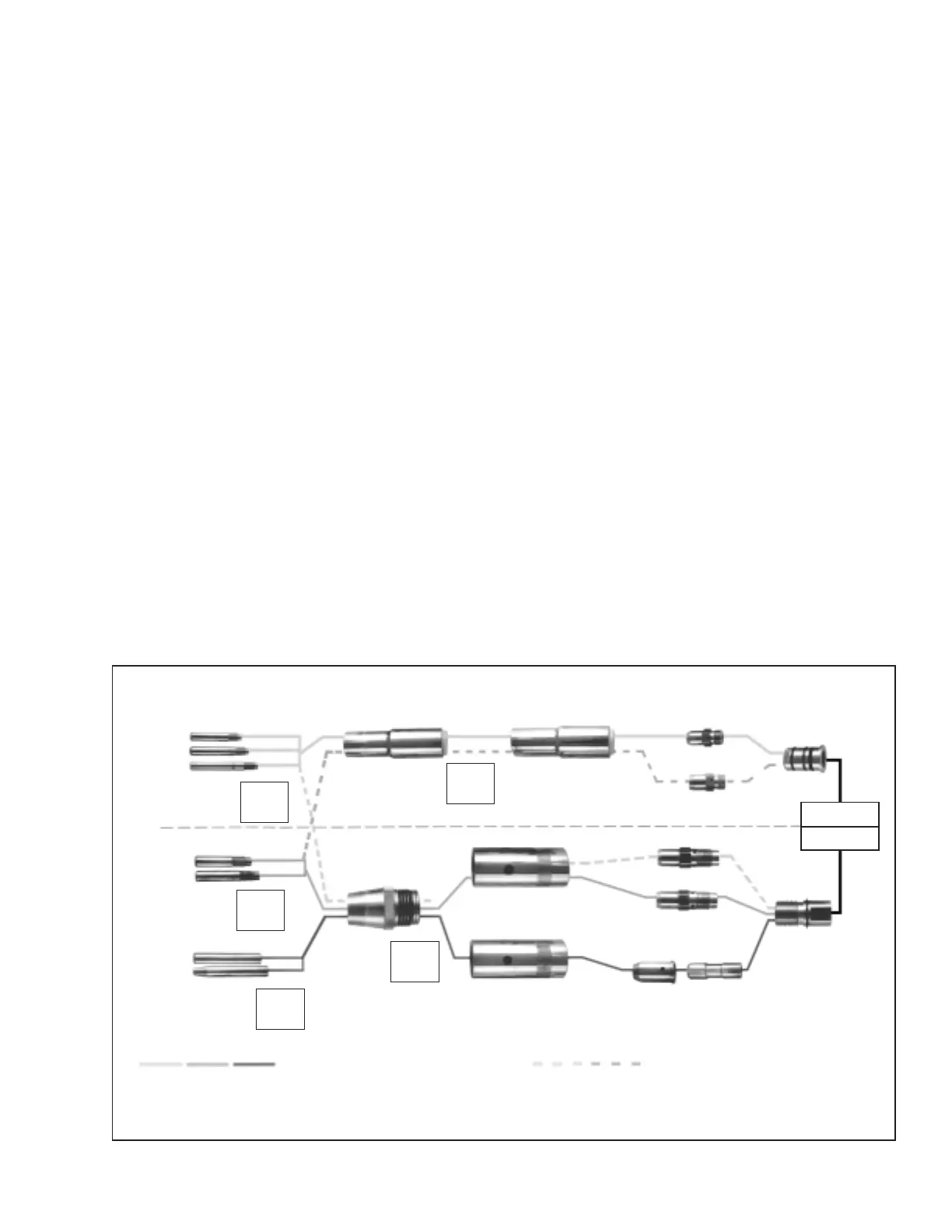

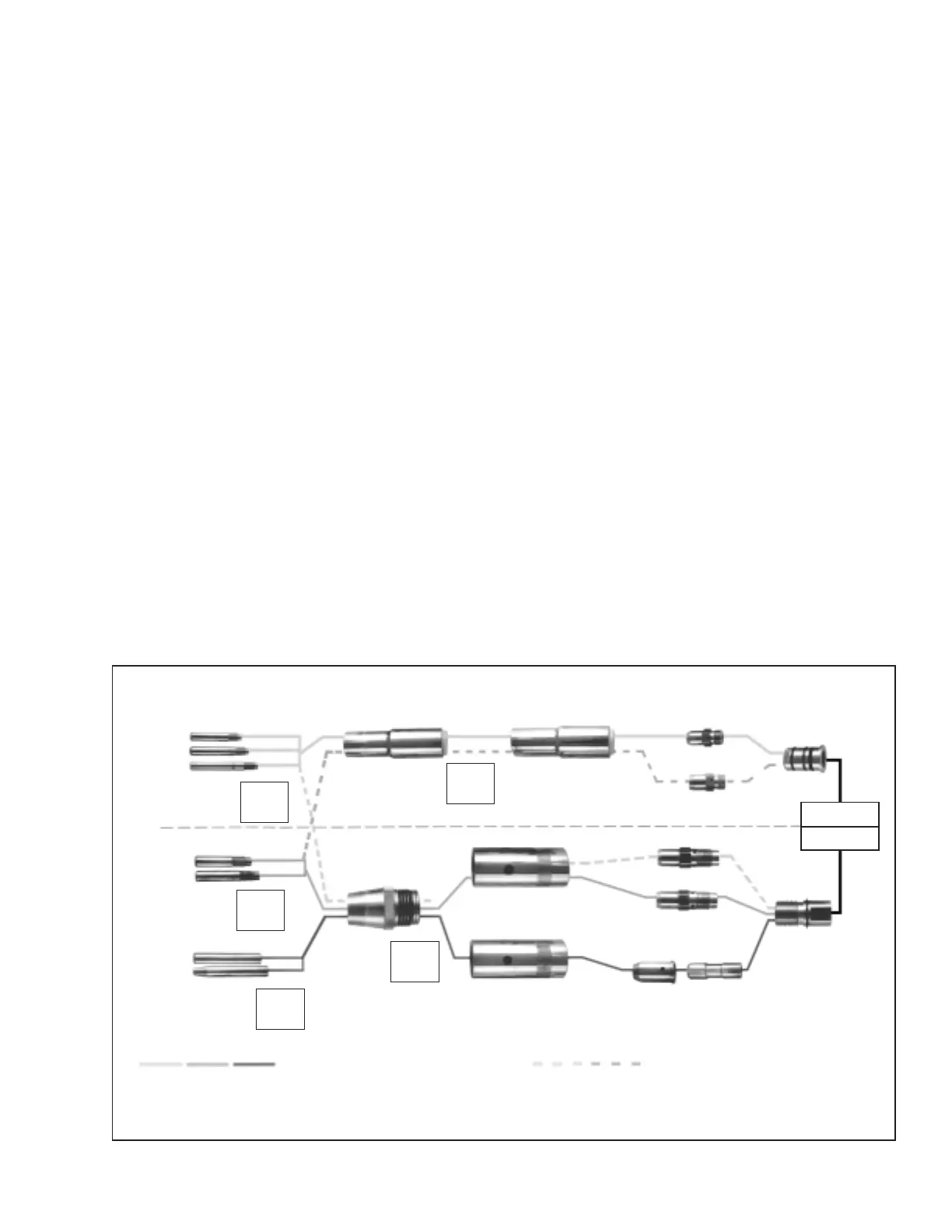

Fig. 1.4, & Tables 1.4.1, 1.4.2 and 1.4.3.

Standard Duty Tips and Nozzles provide good perfor-

mance and service life for the majority of welding

applications.

Heavy Duty Tips, Tubes and Nozzles improve the per-

formance and extend the service life when used with

high current applications, high spatter wires, pulsed arc

mig and when used in confined areas.

Extra Heavy Duty (brass) Slide-on Nozzles provide

improved service life when subjected to extreme im-

pact abuse.

Extra Heavy Duty Threaded Nozzles and Heavy Duty

Tips and Tubes extend the rating of the MT-400 from

400 amps to 500 amps @ 60% duty cycle.

Accessory Selection - Assembly Guide .. see Fig. 1.4

Contact Tips and Tubes .................... see Table 1.4.1

Nozzles (slip-on or threaded) ............ see Table 1.4.2

Liners ............................................... see Table 1.4.3

Figure 1.4 Accessories Selection - Assembly Guide

To select correct accessories, choose tip based on wire and follow Guide Chart to determine nozzle and adaptors.

CONTACT TIPS

AND TUBES

STANDARD DUTY CONTACT TIPS

ADAPTORS

NOZZLES

SLIDE ON SELF INSULATED NOZZLES

MT-200

MT-400

STANDARD DUTY

SEE TABLE

1.4.1

FOR PART

NUMBERS

.023" M or L .052" S or M

.030" M or L 1/16" S or M

.035" M or L 5/64" S or M

.045" - 3/64" S, M or L

SHORT (S)

MEDIUM (M)

LONG (L)

SEE TABLE

1.4.1

FOR PART

NUMBERS

#6 TAPERED #12

#8 #12 SPOT

#10

EXTRA HEAVY

DUTY

HEAVY DUTY

#8

#10

#12

#12 SPOT

#12 BRASS

STANDARD ACCESSORIES

SEE TABLE

1.4.2

FOR PART

NUMBERS

HEAVY DUTY CONTACT TIPS

EXTRA HEAVY DUTY

THREADED NOZZLES

SHORT (S)

MEDIUM (M)

.045" - 3/64" M 1/16" M

.052"M 5/64" M

3/32" M

SEE TABLE

1.4.1

FOR PART

NUMBERS

HEAVY DUTY CONTACT TUBES

SHORT (S)

MEDIUM (M)

.035" M 1/16" M

.045" - 3/64" M 5/64" S

.052" M 3/32" S

SEE TABLE

1.4.2

FOR PART

NUMBERS

#8

#10

#12

#16 SPOT

P/N 948785

P/N 17766 (.045" - 1/16")

P/N 948786 (5/64" - 3/32")

P/N 17135

P/N 17136

P/N 17154

P/N 17318

P/N 948793

COLLET BODY

COLLET

PRIMARY USE OF ACCESSORIES

ALTERNATE USE OF ACCESSORIES

ACCESSORIES FOR EXTENDED RATING

*

NOZZLE ADAPTOR

EXTRA HEAVY

DUTY

ADAPTOR

TIP ADAPTOR

TIP ADAPTOR

P/N 17983

P/N 17984

P/N 999452

NOZZLE

ADAPTOR

* Using Heavy Duty contact tips or tubes and Extra Duty threaded

nozzles will increase the rated capacity of the MT-400 to 500 amps.

II. INSTALLATION

1. Install the proper feed roll (see Table 1.3) to the

wire feeder. Refer to the wire feeder booklet for

installation and adjustment details.

2. Connect the proper wire outlet guide (see Table

1.3) to the wire feeder connector assembly as

shown in figure 1.3.

3. Secure the outlet guide into the front clamp of the

accessory support assembly on the wire feeder

(refer to wire feeder instruction booklet).

4. Connect the power cable, gas hose, and switch

cord to the wire feeder (see Fig. 2.1)

5. Remove retaining pin on wire feeder connector;

insert torch inlet fitting fully; and then reinsert re-

taining pin to lock fitting in place. Be sure retaining

pin is completely pushed in before feeding the wire.

6. Use the inching switch on the wire feeder to inch

the wire through the torch.

7. The torch is now ready to operate. Refer to your

wire feeder instruction booklet for operating de-

tails.

Loading...

Loading...