Do you have a question about the ESAB PCM-750i and is the answer not in the manual?

Guidance on personal protective equipment and hazard awareness for welding and cutting operations.

Precautions to prevent fires and explosions caused by sparks, hot metal, or flammable materials.

Warning and safety measures to prevent severe injury or death from electrical shock.

Information on potential health effects of EMF and procedures to minimize exposure.

Safety measures regarding ventilation and protection from toxic fumes and gases during operation.

Safe practices for handling compressed gas cylinders to prevent rupture or gas release.

Guidelines for safe maintenance procedures and the importance of qualified personnel.

References to other publications for further safety information on welding and cutting.

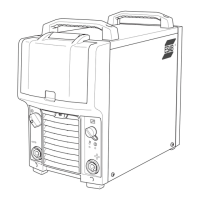

Introduction to the PCM-750i as a compact, self-contained plasma cutting system.

Details the manual's purpose: providing installation and operation information for the PCM-750i.

Lists PCM-750i cutting packages available through ESAB dealers with their part numbers.

Presents key technical specifications for the PCM-750i plasma cutting machine.

Provides guidance for proper installation to ensure satisfactory and trouble-free operation.

Specifies the necessary equipment, including air supply requirements, for the PCM-750i.

Details optimal location criteria for the PCM-750i, emphasizing ventilation and clearance.

Instructions for inspecting the unit for damage and ensuring proper setup.

Guidance on correctly connecting the PCM-750i to the primary electrical power supply.

Critical safety warnings and precautions to follow before and during operation.

Description of the function and operation of the PCM-750i's main controls and indicators.

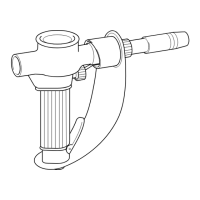

Step-by-step instructions for performing plasma arc cutting using the PT-27 torch.

Identifies common cutting issues and their probable causes for troubleshooting.

General advice for maintenance, emphasizing qualified personnel and safety.

Recommended procedures for regular inspection and cleaning of the PCM-750i.

Instructions for maintaining and assembling consumable parts for the PT-27 torch.

Procedure for disassembling and cleaning the flow switch for proper air flow detection.

General approach to troubleshooting control malfunctions using diagrams and tools.

A systematic guide with flowcharts to diagnose and resolve common operational problems.

Guidelines for ordering replacement parts, emphasizing part number and unit serial number.

Instructions and contact information for ordering genuine ESAB parts and accessories.

Contact information for order entry, changes, availability, pricing, and returns.

Contact details for troubleshooting welding equipment and warranty returns.

Contact information for technical applications, performance features, and specifications.

How to request manuals, brochures, and other documentation.

Contact details for obtaining repair estimates and checking repair status.

Information on training programs, school information, and registration.

Contact information for assistance with welding processes.

Contact information for help with consumables related to welding equipment.

| Brand | ESAB |

|---|---|

| Model | PCM-750i |

| Category | Welding System |

| Language | English |

Loading...

Loading...