Do you have a question about the ESAB POWERCUT-1500 and is the answer not in the manual?

Safety measures for personal protection against arc rays, noise, hot metal, and sparks.

Precautions to prevent fires and explosions caused by heat, sparks, slag, and hot metal.

Safety guidelines to prevent severe injury or death from electrical shock hazards.

Awareness of potential dangers from EMF and procedures to minimize exposure.

Health hazards from fumes/gases and ventilation requirements during cutting.

Safe practices for handling compressed gas cylinders to prevent rupture or injury.

Importance of proper maintenance to prevent injury, death, or equipment failure.

References for further information on safe practices for welding and cutting.

Explains the meaning of warning symbols used throughout the manual.

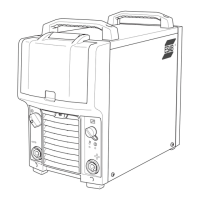

Overview of the PowerCut-1500 plasma cutting system and its capabilities.

Purpose of the manual to provide installation and operation information.

Technical details including cutting capacity, input/output, dimensions, and weight.

Information about the PT-32EH torch used with the PowerCut-1500.

Part numbers and configurations for ordering the PowerCut-1500 package.

List and descriptions of available accessories for the PowerCut-1500.

Details the items included in the PT-32 spare parts kit.

Importance of proper installation for satisfactory operation of the cutting package.

Specifies the necessary equipment for the cutting operation, including air supply.

Guidelines for placing the equipment to ensure proper cooling and minimize exposure.

Procedures for inspecting the equipment for damage upon receipt and before use.

Instructions for connecting the power source to the primary electrical input.

How to change the input voltage setting on the PowerCut 1500 unit.

Instructions for connecting the air supply to the filter-regulator.

Explanation of the functions of the control panel buttons and switches.

Description of the indicator lights and what they signify during operation.

Step-by-step procedures for performing plasma arc cutting.

Common problems encountered during cutting and their probable causes.

Guidelines for performing maintenance by experienced personnel.

Recommendations for regular inspection and cleaning of the unit.

Information on handling and replacing consumable parts for the PT-32 torch.

Precautions and procedures for handling and replacing IGBT modules.

General guidance on troubleshooting common issues with the equipment.

Steps to diagnose and resolve issues with the power indicator light.

Procedures to identify and fix problems related to air flow.

Troubleshooting steps when the power is on but the torch switch has no effect.

Diagnosis for fault lights indicating line voltage, gas flow, or temperature issues.

Steps to troubleshoot when air is supplied but the torch switch does not activate.

How to resolve issues where the main arc fails to transfer.

Identifying causes for suboptimal cutting results.

Troubleshooting steps when the air supply fails to stop.

Common reasons and solutions for difficulty in starting the main arc.

Voltage checks for control board components and test points.

Understanding the sequence of operations for trigger lock modes.

Overview of illustrated replacement parts for the PowerCut-1500.

Instructions on how to order genuine ESAB replacement parts.

Identifies parts on the front panel of the PowerCut-1500.

Identifies parts on the rear panel of the PowerCut-1500.

Identifies internal components on the lower left side.

Identifies internal components on the left rear side.

Identifies internal components on the left sub-assembly.

Identifies internal components on the right side.

Identifies internal components on the right sub-assembly.

Identifies internal components on the upper left side.

Identifies internal components on the front left side.

| Brand | ESAB |

|---|---|

| Model | POWERCUT-1500 |

| Category | Welding System |

| Language | English |