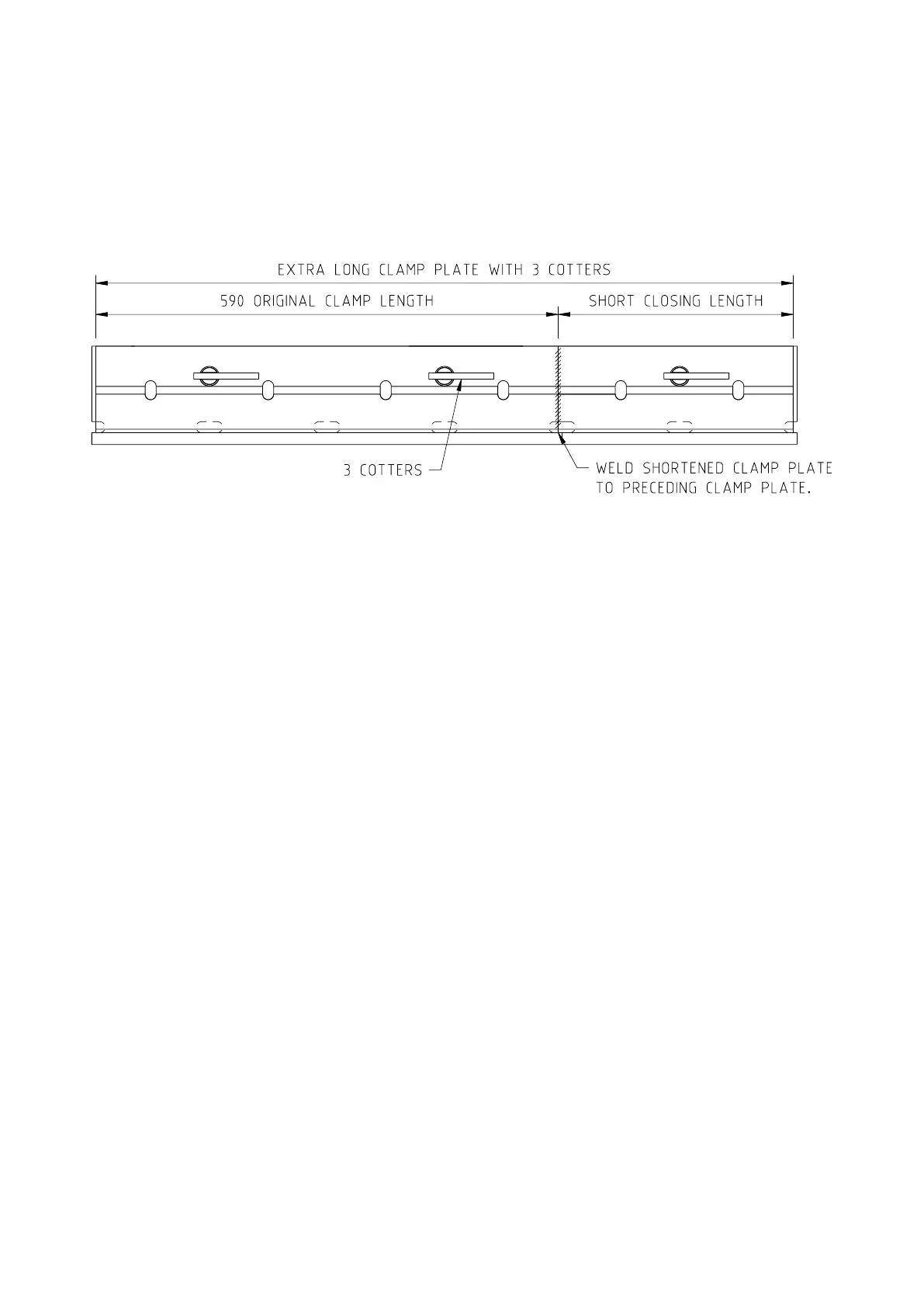

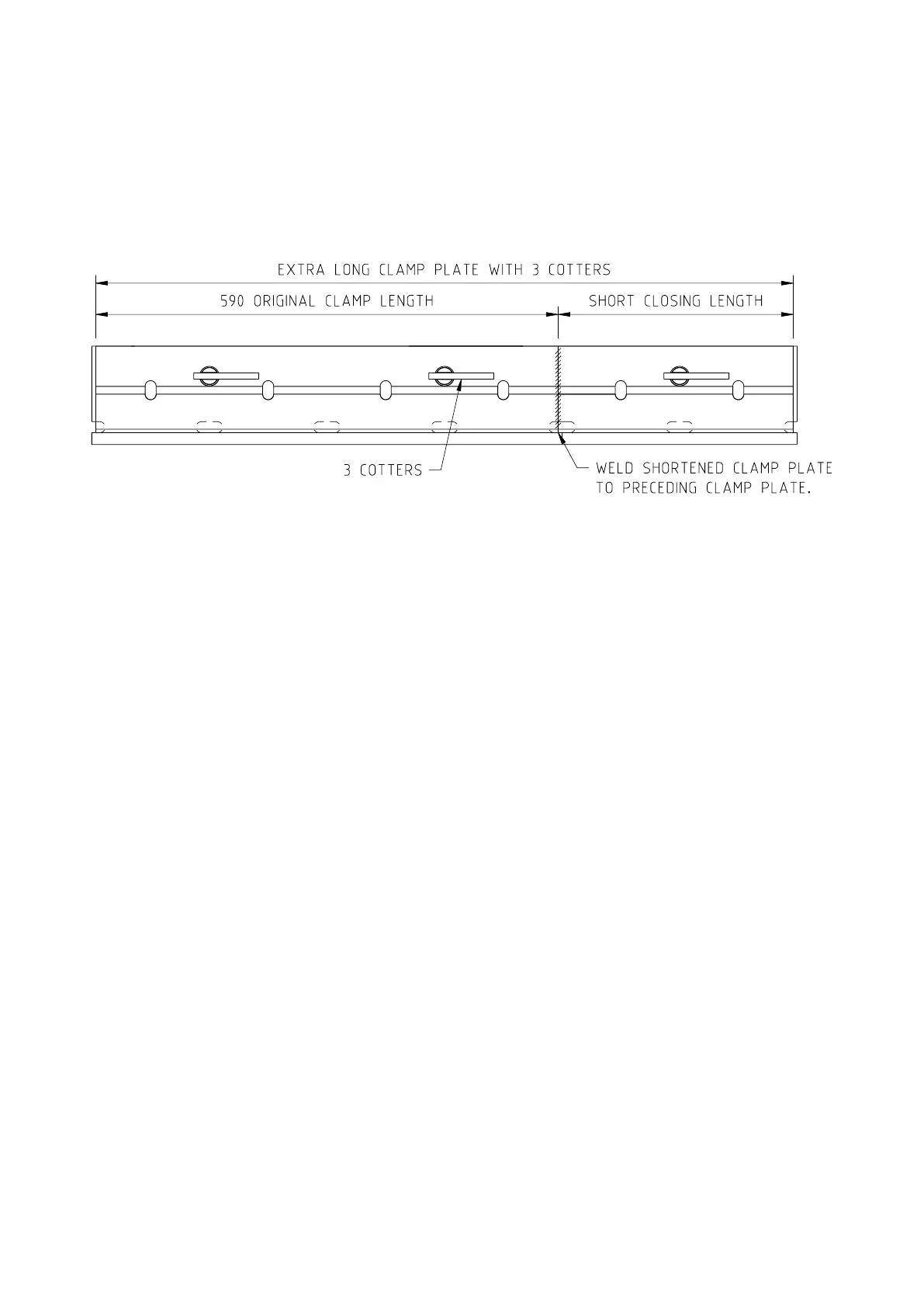

Finally, a Three-Cotter Clamp Plate may be constructed. The Backplate

can be cut to a single cotter and installed as per standard units. The

Clamp Plate is then cut to match the Backplate, and welded to the

adjacent Clamp Plate to form a longer Clamp Plate with three cotters.

Ensure that the fabricated longer Clamp Plate has its holes at the same

centres as the Cotters in the Backplate.

Any of the above methods is acceptable. Again, NEVER install a Clamp Plate with

only a single Captive Wedge or Cotter. A minimum of two Cotters is required

for each Clamp Plate.

4. Grind each plug weld flush with the face of the backing plate if necessary.

5. Measure the required length of skirting rubber required, and cut this length from

the roll supplied. See the cutting procedure following in section 4.2.

6. Insert the skirting rubber from one end, making sure that the correct edge is

downward. Secure the rubber by placing the ESS 2000 clamps plates in

position over the captive wedges, and lightly tapping the wedges to hold the

rubber.

7. Insert a screwdriver in the Clamp plate slot and push down the rubber until it

lightly but uniformly contacts the conveyor belt, loosening the nearest wedge if

necessary. Firmly tap wedges tight and repeat the process for consecutive

clamp plates. Do not overtighten the rubber against the belt, or the wedge.

8. Remove the weld blanket, and any installation debris from the conveyor.

10. Remove danger tags and return conveyor to service, following plant

procedures.

NOTE: IF YOU HAVE ANY PROBLEMS, OR ARE UNCLEAR ON ANY INSTALLATION

STEP, CONTACT ESS ON CUSTOMER SERVICE NUMBER 1800 074 446.

Loading...

Loading...