Only install bulbs rated 16V or higher and with a nominal

current draw, that does not exceed 50 mA or use suitab-

le smoke units such as Seuthe No. 11. If you like to use

LEDs, a resistor with a rating between 470 Ohms and 2.2

kOhms need to be wired in series. Running the LED wit-

hout resistor will lead to their immediate destruction! All

function outputs from AUX3 and higher are following the

NEM660-Standard (VHDM RCN-121, NMRA S.9.1.1.3) are

are so called logic level outputs. It is not possible to con-

nect any external load to such outputs directly. External

power transistors are required. Usually, these are already

installed on the locomotive›s motherboard (if required).

For do it your self projects, ESU is offering appropriate ad-

apter boards (e.g.items 51957 or 51968) with transistors.

SUSI/Logic level-outputs

Alternatively, the two pins on the LokPilot 5 Basic with

21MTC interface that are assigned to the SUSI serial in-

terface can also be configured as logic level outputs. In

this way, the number of available outputs can be increased

by two.

Please remember that the two SUSI-pins, available

on 21MTC, Next18 or PluX can be used as logic le-

vel outputs or Servo control lines alternatively, still

following the standards. You have to check the ac-

tual connection of your locomotive motherboard

to be sure about the function.

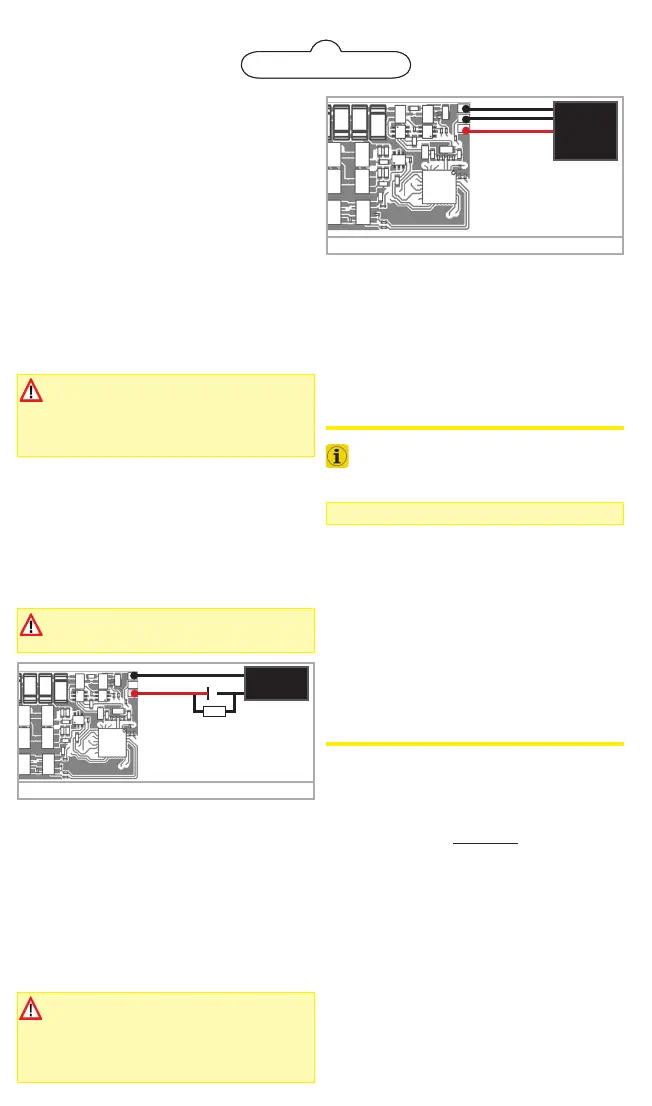

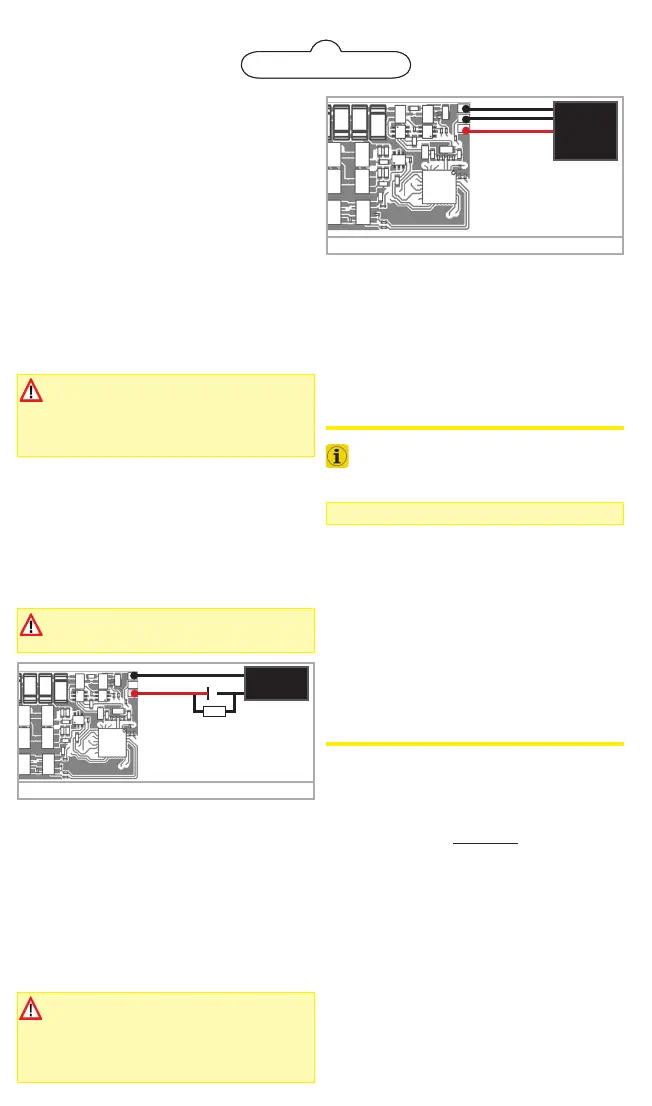

Connecting capacitors

On many older locomotives, the current pickup is not

very reliable. Therefore, power interruptions may cause a

stop or jerky movement when the locomotive travels over

turnouts at low speeds. This can be overcome with buffer

capacitors. The minimum capacity used should be 470uF

/ 25V. Smaller capacitors will not show good results. You

can connect an electrolyctic capacitor following figure 4.

Charging is done trough a 100 Ohms resistor, limiting the

charging current.

The capacitors must be removed or disabled prior

to programming the decoder using the ESU Lok-

Programmer device!

After connecting the PowerPack, you can make the deco-

der switch off after a certain time. CV 113 is responsible

for that. The factory default value of 31 equals to about

1 second. You should set a time between 0.3s and 1s .

For the PowerPack to work, the function output responsib-

le for the charge (AUX9) must be configured to the «Po-

werPackControl» function. Although this should be set up

by default already, you can do this manually also:

Set CV 31 = 16, CV 32 = 0 first.

Then set CV339 = 31.

DCC Operation

The LokPilot 5 Basic works with any DCC system.

Remove any capacitors that are wired into the

track feeders (e.g. ROCO® feeder track). This

could impair the functionality of the decoder.

The address is set to 03 using 28 speed steps .

F1 switches output AUX1

F2 switches output AUX2

F3 switches the switching mode on and off

F4 switches the acceleration and deceleration on/off

F5 switches output AUX3 (if applicable)

F6 switches output AUX4 (if applicable)

F7 switches output AUX5 (if applicable)

F8 switches output AUX6 (if applicable)

DC Operation

The LokPilot 5 Basic are set ex factory to operation on

conventional DC layouts as well. No settings are needed

to be done.

Decoder Settings (Programming)

A list of the most important CV parameters is given later.

These can be changed using any DCC command station. If

your command station supports RailCom®, you can read

CV values on the main.

A list of all decoder parameters can be found in the de-

tailed manual for the LokPilot 5 Basic, which can be down-

loaded from our website www.esu.eu in the «Downloads»

area. The extensive function mapping is also discussed the-

re, and all light functions are explained there, also.

Lenz ABC-Brake Mode

LokPilot 5 Basic supports the ABC braking technique. To

use this function, a group of anti-parallel diodes will be

soldered to one half of the track. The resulting fall of vol-

tage generates an asymmetrical DCC signal that can be

detected by the decoder.

• If you want to stop the decoder no matter in which half

of the track the diodes are set, please set Bit 0 and Bit

1 in CV 27 (CV27=3).

In some operational situations it may happen that the Lok-

Pilot decoder does not detect the ABC braking section.

You can influence the detection sensitivity with the aid of

CV 134. Cange the default value (10) step by step and test

until you achieve the desired result.

Figure 4: 2200mF capacitor at LokPilot 5 Basic

+

-

2200uF

25V

100Ω,1/4 Watts

1N4007

GND

U+

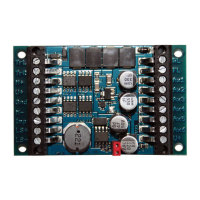

Figure 5: PowerPack at LokPilot 5 Basic

GND

U+

ESU

Power

Pack

Charge

CV 113 buffer time

factory default = 31

(approx 1. second)

PowerPack for LokPilot 5 Basic

You can solder a powerful energy buffer to all LokPilot 5

Basic decoders. The connection diagram figure 5 shows

you how to do it. This «Powerpack» allows your locomo-

tive to keep running for up to 2 seconds without power.

ESU supplies under the item number 54671 or 54672

suitable PowerPack modules. Please do ONLY use these.

• The PowerPack only operates in digital mode. It auto-

matically turns off on analog layouts.

• It may take up to two minutes to fully charge the ca-

pacitor («Goldcap»). Therefore, the time bridged with

the energy buffer depends on the current draw of your

locomotive and the charge-up time.

The time to be bridged with the PowerPack can

be set in CV 113. Output AUX9 needs to be set

to «PowerPackControl» (Should be the default).

Loading...

Loading...