74 www.eta.co.at

Function block [special conveyor] and [external conveyor] ETAtouch controller

6.11 Function block [special

conveyor] and [external

conveyor]

Special types of conveying systems

This function block is used with wood chip boilers to

control special versions of fuel conveyor systems. For

example:

• Silo conveyor system

• Double agitator (two agitators supply one boiler)

• Intermediate conveyor screw (several conveyor

screws in series)

Conveyors with a drive power up to 1.1 kW are

controlled in the [Special conveyor] ([SpConv])

function block. This covers all ETA conveyors.

Conveyors with a higher drive power are controlled in

the [Ext. conveyor] ([ExtConv]) function block.

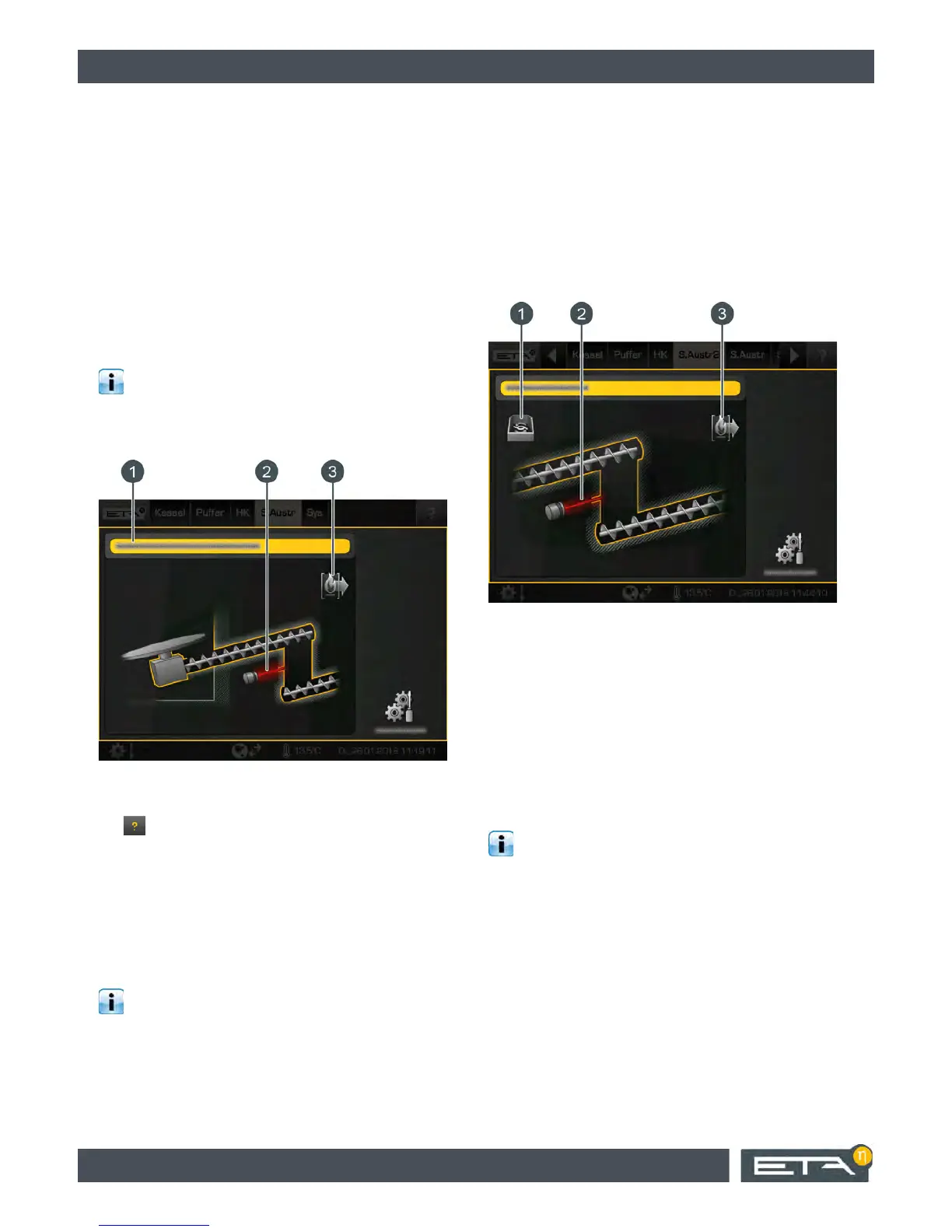

1 Operating condition and information.

A description of the operating conditions can be

found in the integrated Help menu by pressing the

button.

2 Light barrier (only with [Light barrier in drop chute]

option)

3 Consumers of the conveying system (the boiler)

The agitator and the screw are shown in green as soon

as they begin to transport fuel. They are displayed in

grey when not in operation or when the screw is turning

in reverse in order to remove a blockage.

A light barrier for the drop chute is supplied ex-

works for controlling the fuel conveying system.

For external conveying systems, the light beam is

available as an option.

If the drop chute is filled with enough fuel, the light

barrier is interrupted and displayed in red. If the light

barrier is displayed in green, there is no fuel or insuffi-

cient fuel in the drop chute.

6.11.1 Intermediate conveyor screw

Intermediate conveyor screw overview

When several conveyor screws in series are used to

transport fuel to the boiler, they are referred to as inter-

mediate conveyor screws.

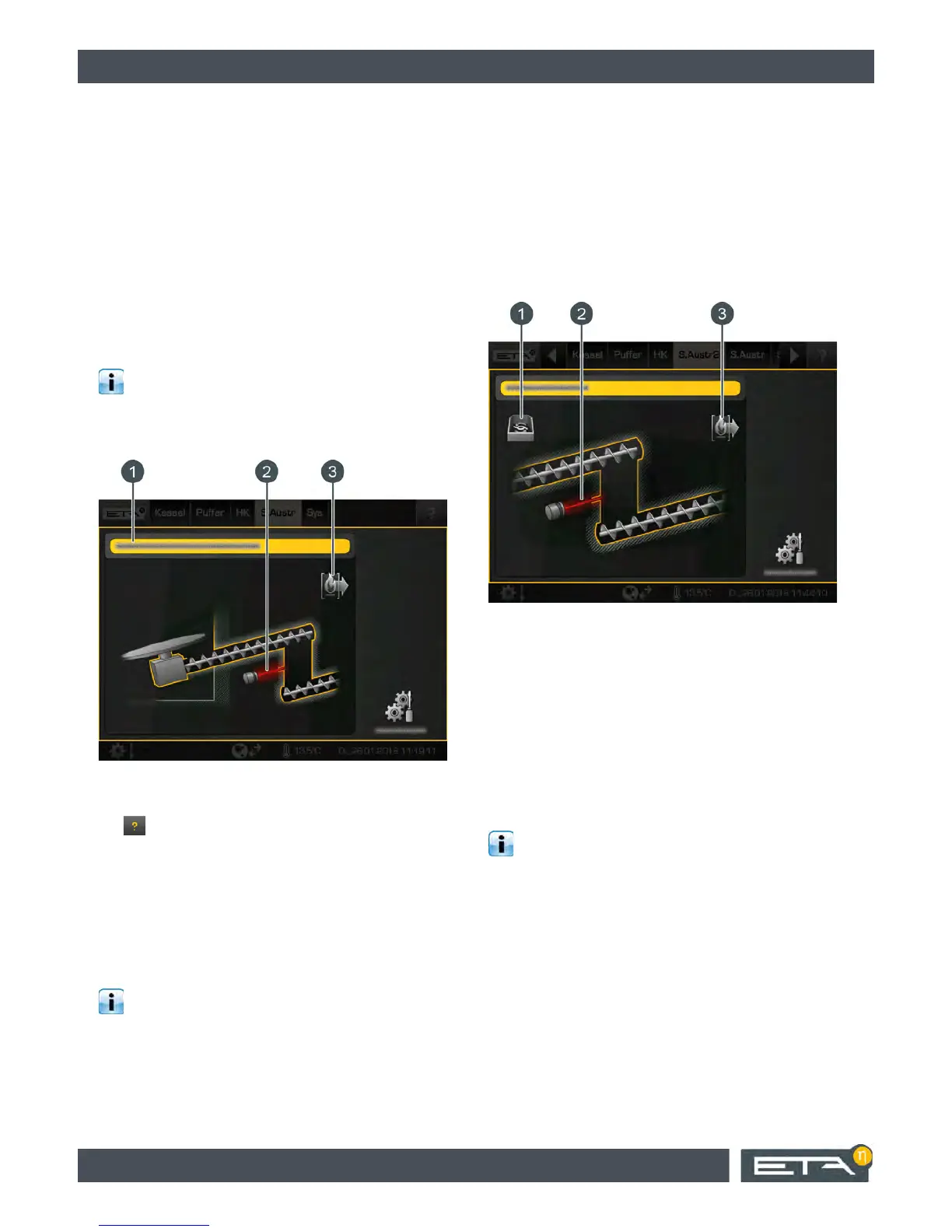

1 Producer for the intermediate conveyor screw

(conveying system)

2 Consumer of the intermediate conveyor screw

(boiler)

3 Light barrier (only with [Light barrier in drop chute]

option)

The intermediate conveyor screw appears green when

it is turning in the discharge direction. The intermediate

conveyor screw is shown in grey when not in operation

or if it is turning against the discharge direction in order

to remove a blockage.

A light barrier is also supplied with the intermedi-

ate conveyor screw ex-works for controlling the

fuel transport. For external conveying systems, the

light beam is available as an option.

If the drop chute is filled with enough fuel, the light

barrier is interrupted and displayed in red. If the light

barrier is displayed in green, there is no fuel or insuffi-

cient fuel in the drop chute.

6.11.2 Double agitator

Double agitator overview

When two agitators transport the fuel to a discharge

screw and from there to the boiler, the configuration is

called a double agitator. Each agitator is shown in its

own function block.

Loading...

Loading...