38

Torch operating modes

N.B.! For information on how to set the available parameters,

and on the setting range and units of these parameters, please

see the section headed "The set-up menu".

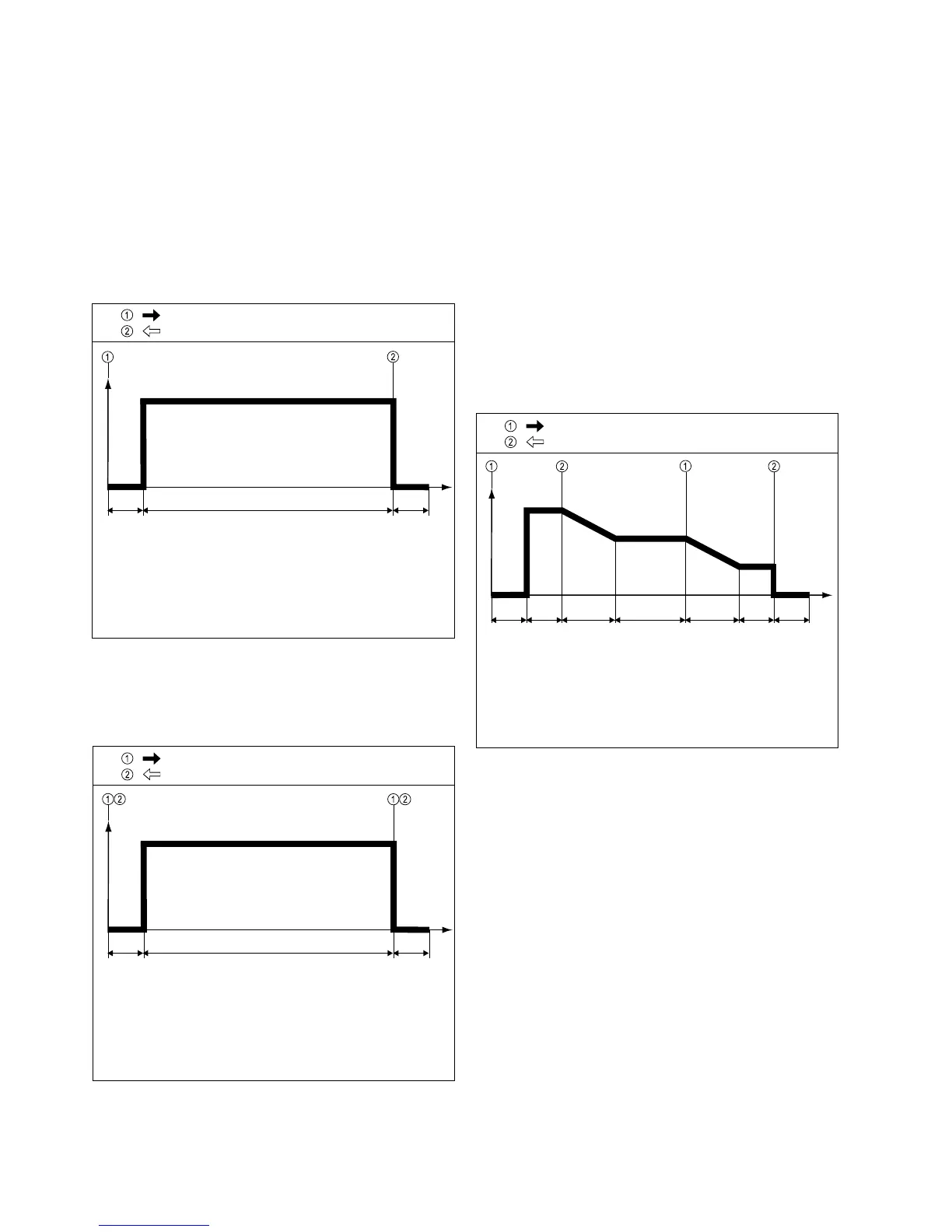

2-step mode

2-step operation is suitable for

- tacking-jobs

- short weld-seams

- Automatic and robot welding

4-step mode

4-step mode is suitable for longer weld seams.

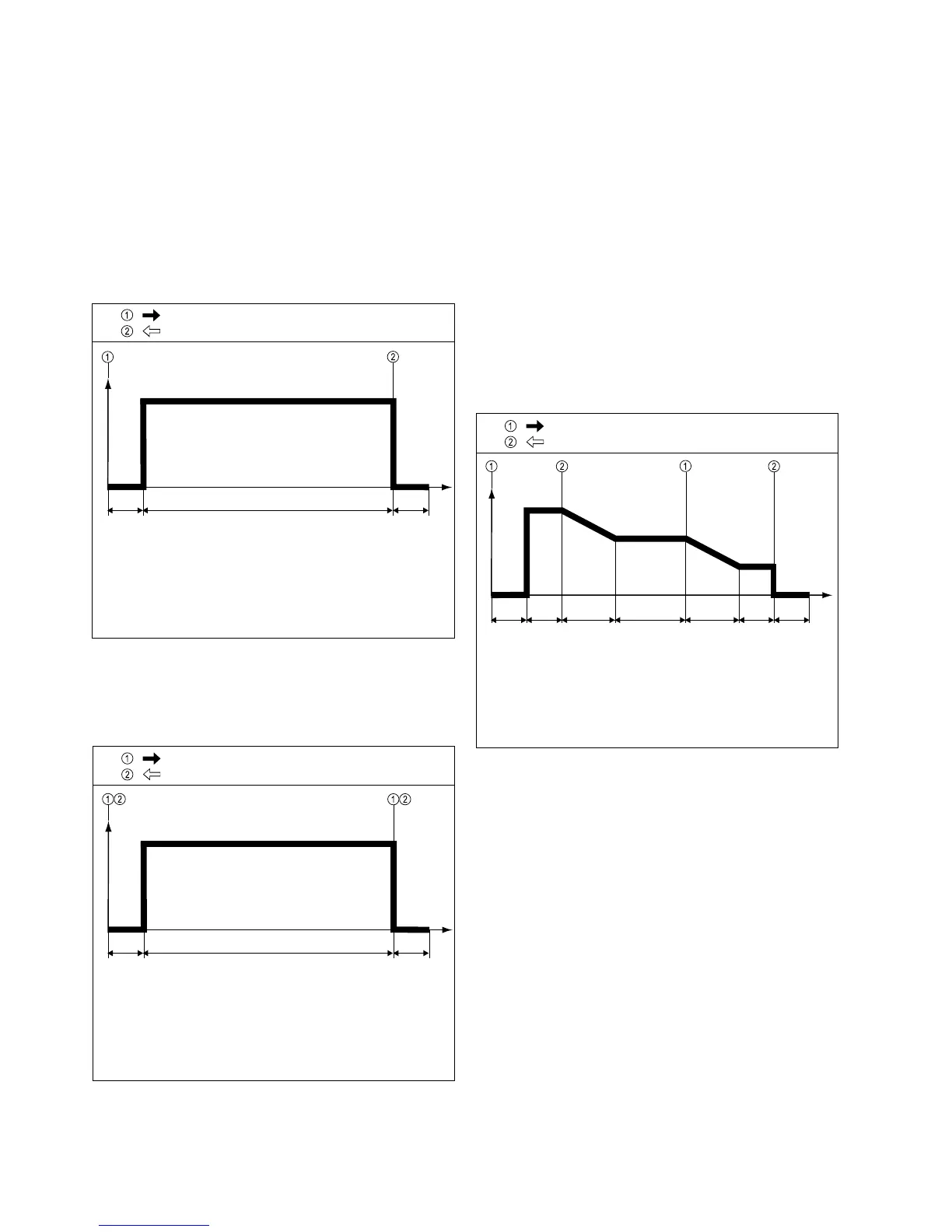

4-step mode (aluminium)

The "4-step mode (aluminium)" is particularly suitable for

welding aluminium materials. The special pattern of the current

curve takes account of the high thermal conductivity of alumi-

nium:

- Starting current (I-S): For rapid heating-up of the base

metal, despite the high thermal dissipation at the start of

welding

- Slope (SL): The starting current is continuously lowered

down as far as the welding current

- Welding current: For an even, uniform thermal input into

the base metal, which is heated up by advancing heat

- Slope (SL): The welding current is continuously lowered

down as far as the final current

- Final current (I-E): By preventing local overheating of the

base metal by heat build-ups towards the end of welding,

this eliminates any risk of weld drop-through.

Fig.7c 4-step mode (aluminium)

Press and hold the torch trigger

Release the torch trigger

Fig.7a 2-step mode

Press and hold the torch trigger

Release the torch trigger

I

t

Press the torch trigger

Release the torch trigger

Welding current

Gas pre-flow time (GPr)

Gas post-flow time (GPo)

Fig.7b 4-step mode

I

t

Welding current

Gasv pre-flow time (GPr)

Gas post-flow time (GPo)

I

t

Welding current

Gas pre-flow time (GPr)

Gas post-flow time (GPo)

Starting current (I-S)

Slope (SL)

End current (I-E)

Slope (SL)

Loading...

Loading...