42

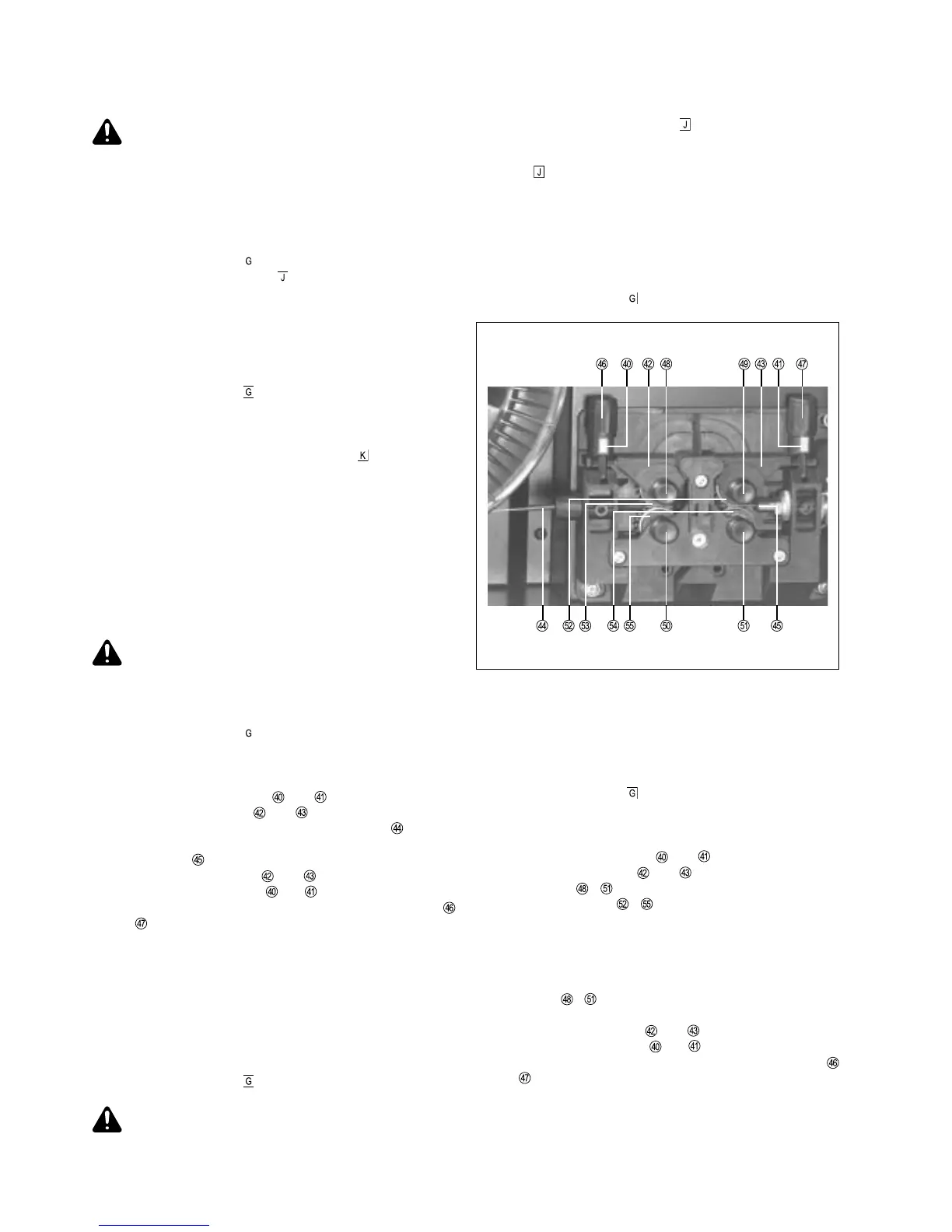

Changing the feed rollers

In order to achieve satisfactory wire travel, the feed rollers must

be suitable for the diameter and alloy of the wire to be welded.

- Shift the mains switch into the “O” position

- Open the wire-spool cover (DS III) or the left side panel of the

TotalArc² 3000 power source

- Remove the left side panel of the power source

- Pivot the clamping devices and forwards

- Pull the pressure levers and upwards

- Pull out axles -

- Remove feed rollers -

- Insert new feed rollers

N.B.! Insert the feed rollers in such a way that you can still see

and read the designation for the wire diameter.

- Push axles - back in again - the anti-twist lock of each

axle must latch into place

- Push the pressure levers and downwards

- Pivot the clamping devices and into the vertical position

- Set the contact pressure by means of the clamping nuts

and

- Close the wire-spool cover or side panel

Fig.8 4-roller drive

Warning! The coolant circulation must be checked at

regular intervals while the machine is in operation - it

must be possible to see that the return-flow to the

reservoir is working correctly.

Setting the shielding-gas rate

- Plug in the mains plug

- Shift the mains switch into the "I" position

- Press the “Gas test” button

- Turn the adjusting-screw on the underside of the pressure

regulator until the manometer indicates the desired flow-

rate

Mounting the wire spool

- Shift the mains switch into the “O” position

- Open the wire-spool cover (DS III) or the left side panel of the

TotalArc² 3000 power source

- Take off the side panel from the power source

- Mount the wire spool onto the spool holder - the right way

round

- Latch the locking bolt into the opening provided on the body

of the spool

- Adjust the braking force with the clamping screw

- Replace the wire-spool cover or side panel

N.B.! The brake should always be adjusted so that the wire

does not continue unreeling after the end of welding - but

without overtightening the clamping screw, as this would cause

motor overload.

Warning! Make sure that the wire-spool is sitting firmly

on the spool holder.

Feeding in the wire electrode

- Shift the mains switch into the “O” position

- Open the wire-spool cover (DS III) or the left side panel of the

TotalArc² 3000 power source

- Remove the left side panel of the power source

- Pivot the clamping devices and forwards

- Pull the pressure levers and upwards

- Insert the wire electrode though the infeed tube of the 4-

roller drive and around 5 cm into the infeed tube of the

welding torch

- Push the pressure levers and downwards

- Pivot the clamping devices and into the vertical position

- Set the contact pressure by means of the clamping nuts

and

N.B.! Set a contact pressure that is high enough to ensure

smooth wire feed, but not so high that the wire electrode is

deformed.

- Arrange the hosepack in as straight a line as possible

- Detach the gas nozzle from the torch

- Unscrew the contact tube

- Plug in the mains plug

- Shift the mains switch into the "I" position

Warning! During the wire-infeed operation, hold the

welding torch facing away from your body.

- Press the wire-inching button until the wire electrode

protrudes out of the end of the torch

- To end the wire-infeed operation, release the wire-inching

button

N.B.! The wire spool must not continue to unreel after you

release the torch trigger. Re-adjust the brake if necessary.

- Screw in the contact tube

- Fit the gas nozzle

- Close the wire-spool cover or side panel

- Shift the mains switch into the “O" position

Loading...

Loading...