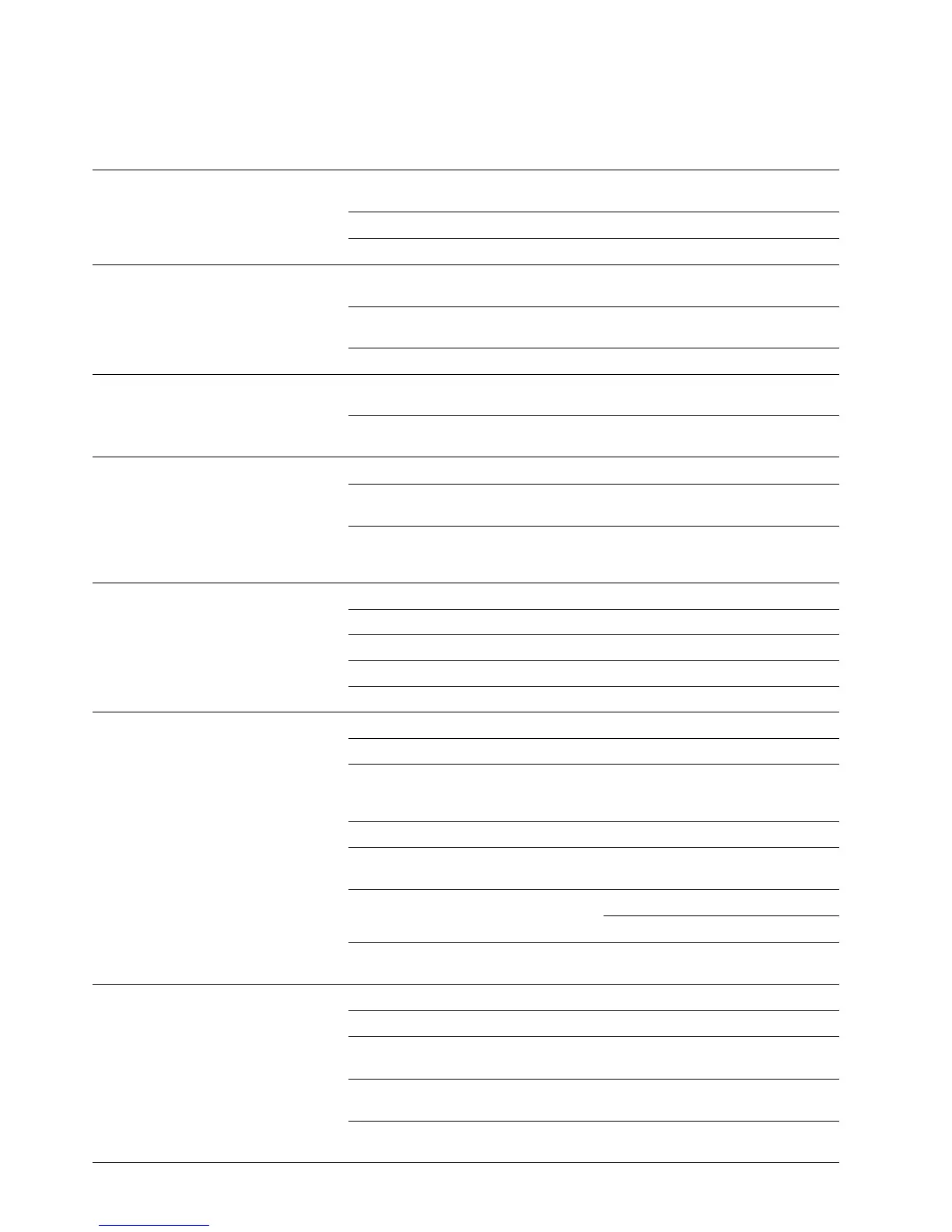

50

Poor welding properties Wrong welding parameters Check settings

Poor earth connection Ensure good contact to workpiece

Not enough shielding gas, or none at all Check pressure regulator, gas hose,

gas solenoid valve, torch gas connec-

tion etc.

Welding torch is leaking Change the torch

Wrong contact tube, or contact tube is

worn out

Change the contact tube

Wrong wire alloy and/or wrong wire dia-

meter

Check the wire spool

Check the weldability of the base metal

Shielding gas is not suitable for this wire

alloy

Use the correct shielding gas

Irregular wirefeed

Welding wire forms a loop between the

feed rollers and the wire inlet nozzle of

the welding torch

Braking force is set too high Loosen the brake

Contact tube is too narrow Use a suitable contact tube

Wirefeed inner liner in the welding torch

is defective

Check the wire inner liner for kinks, dirt

etc.

Wirefeed rollers are unsuitable for the

wire being used

Use suitable wirefeed rollers

Wirefeed rollers have wrong contact pres-

sure

Optimise the contact pressure

Control plug is not plugged in Plug in the control plugMachine does not function when the

torch trigger is pressed

Mains switch is ON and indicators are

lit up

Earth connection is wrong Check the earth connection and clamp

for correct polarity

No welding current

Mains switch is ON and indicators are

lit up

Check interconnecting cable

Exchange the torchBreak in the current cable in the welding

torch

Interconnecting cable defective or not

connected up properly (not on TotalArc²

3000)

Welding torch / torch control lead defec-

tive

Exchange the torch

No shielding gas

All other functions are OK

Gas solenoid valve is defective Change the gas solenoid valve

Gas cylinder is empty

Gas pressure regulator is faulty

Gas hose is not mounted or is damaged

Welding torch is defective

Change the gas cylinder

Change the gas pressure regulator

Mount / change the gas hose

Change the welding torch

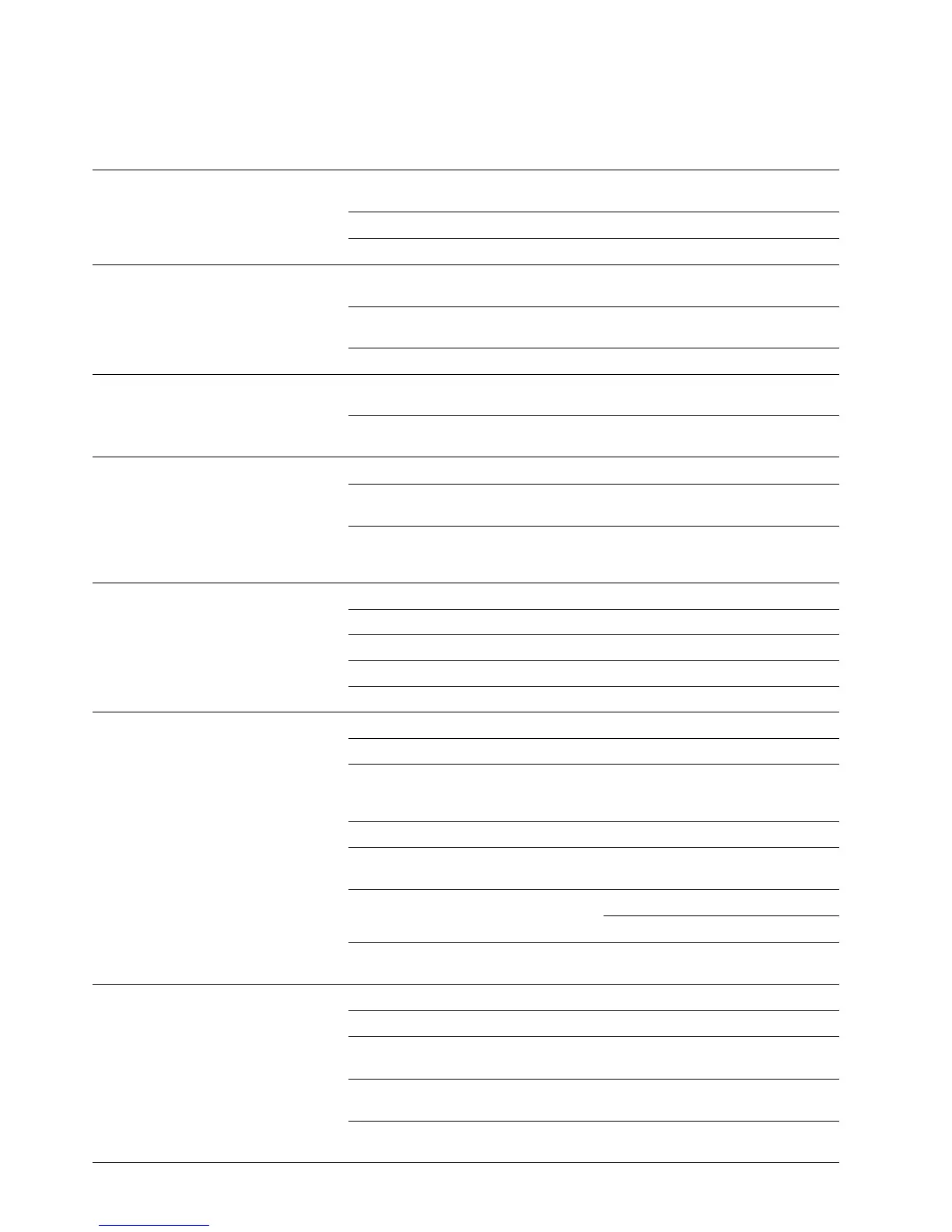

TOTAL ARC

2

3000 / 4000 / 5000 power source

Fault Cause Remedy

Check mains supply lead, make sure

mains plug is plugged in

Machine does not function

Mains switch is ON, but indicators are

not lit up

Do not exceed duty cycleNo welding current

Mains switch is ON, overtemperature

indicator is lit up

Mains outlet socket or plug is faulty

Break in mains lead, mains plug not

plugged in

Mains fuse is faulty

Change faulty components

Change mains fuse

Fan in power source is defective

Machine is overloaded, duty c. has been

exceeded

Thermostatic cut-out system has been

tripped

Change the fan

Wait until machine automatically co-

mes back on after end of cooling phase

Loading...

Loading...