4

PMC & eco-PMC SERIES FORCED DRAFT EVAPORATIVE CONDENSERS

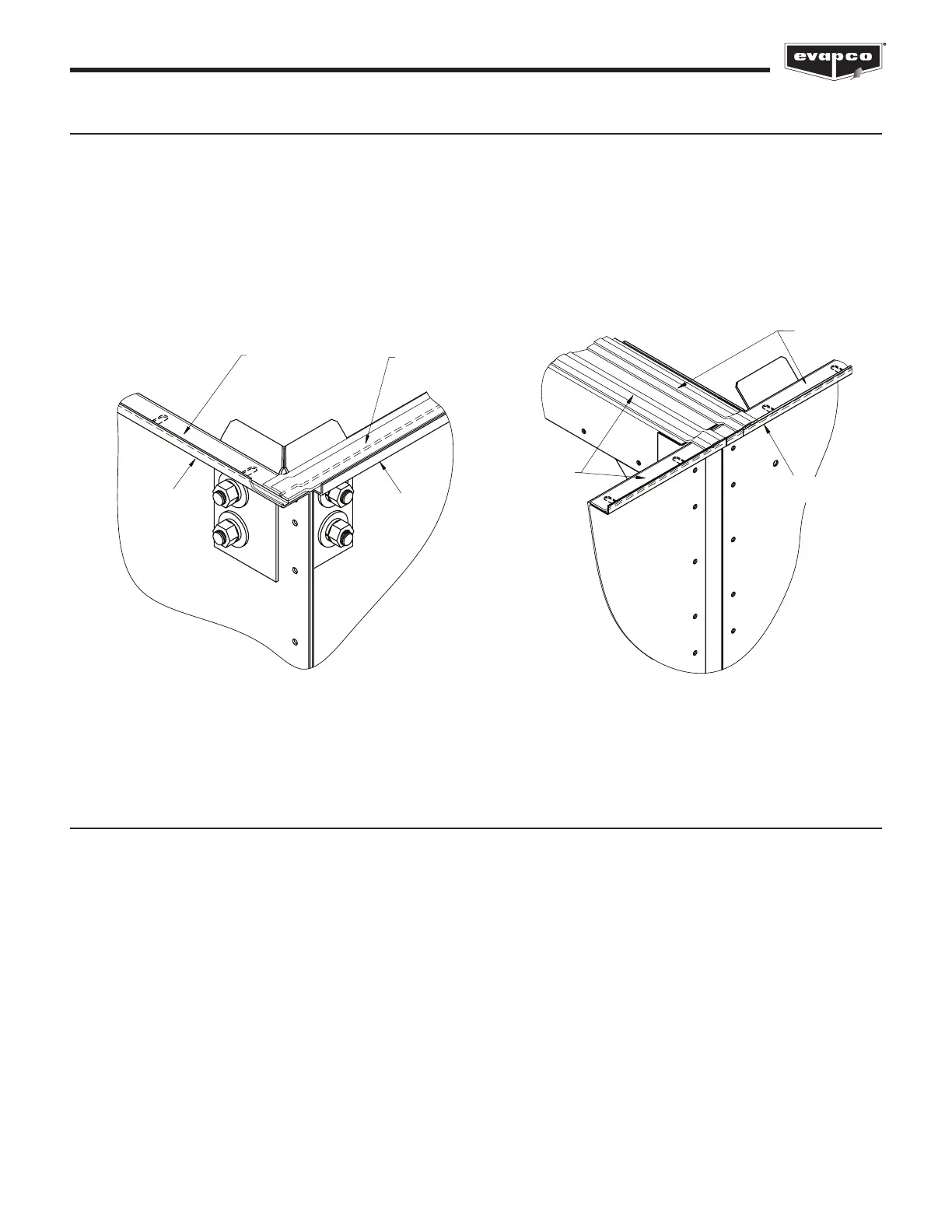

Applying Sealer Tape

Once the bottom section has been set on the supporting steel and bolted in place, wipe the top flanges to remove any dirt or moisture.

Place sealer tape over the mounting hole centerline on the side flanges. Apply two strips of sealer tape, one partially overlapping the

other, on the end flanges. (NOTE: Sealer tape is applied completely around the perimeter of the section.)

The sealer tape should overlap on the corners as shown in Figure 5. Do not splice the sealer tape along the end flanges and preferably

not on the side flanges if it can be avoided. Always remove the paper backing from the sealer tape.

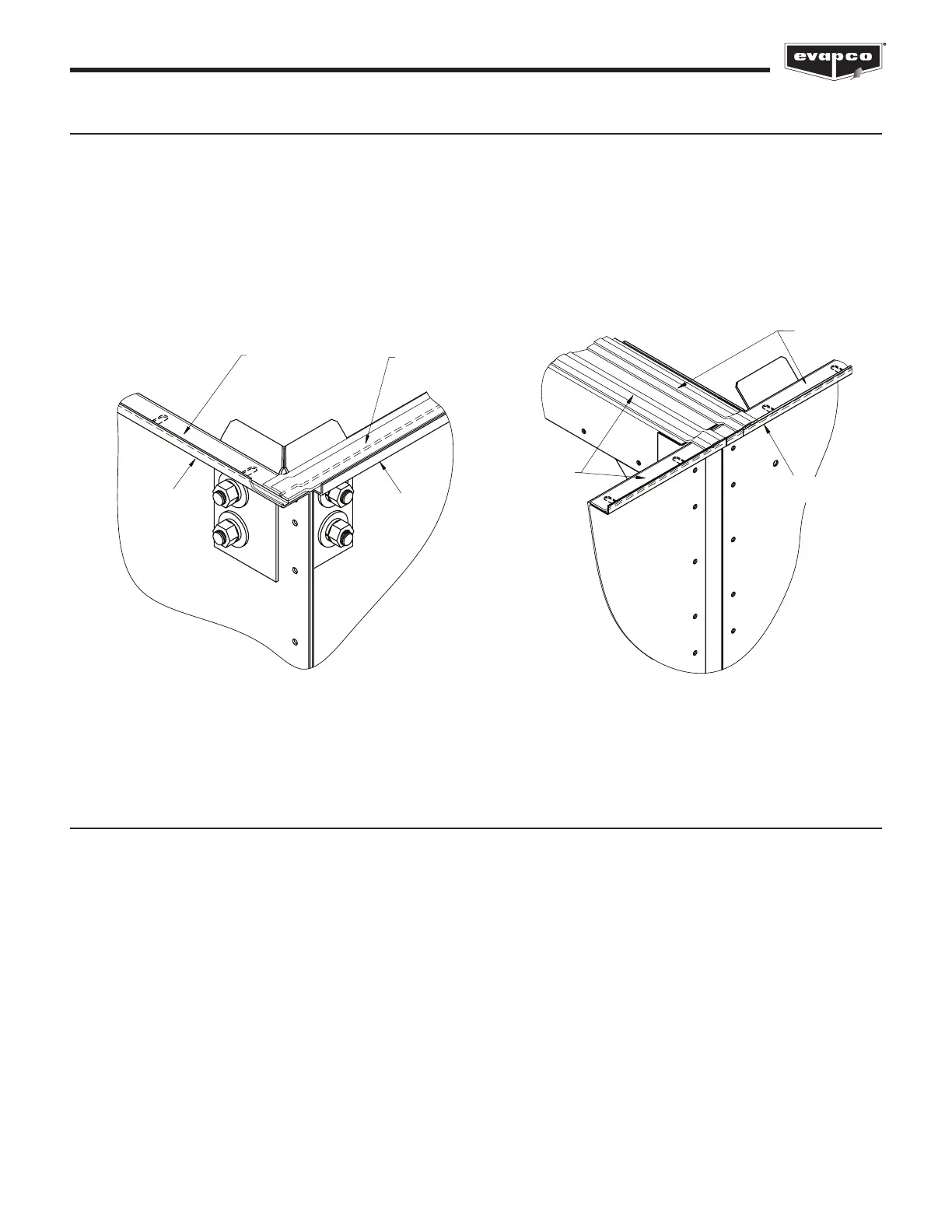

For units which have two casing sections, sealer tape must be applied to all internal flanges (Figure 6).

Rigging the Heat Transfer Casing (Top) Section

U-bolts or li points are located inside the casing on the four corners of the coil for small single coil casing sections. These li points are

for liing and final positioning (Figure 7). On larger casing sections, the liing points are on the outside of the casing section (Figures 8

and 9).

The end and center eliminator sections on small, single casing sections should be removed before liing from the U-bolts or li points.

See Table 4 for the minimum “H” dimensions for rigging the casing section. Always use safety slings for extended lis or where any

hazard exits. See the “Extended Lis” section in this bulletin.

NOTE: Use all of the U-bolts or li points provided for liing.

CAUTION: On units shipped as two separate sections, do not assemble sections and attempt to li the entire unit. The

U-bolts and li points are designed to carry only the weight of their individual section.

SIDE

FLANGE

END

FLANGE

SEALER

TAPE

SEALER

TAPE

SEALER

TAPE

SEALER

TAPE

SIDE

FLANGE

Figure 5 – Proper Sealer Tape Application Figure 6 – Sealer Detail for Center Joint of

Units with Two or More Casing Sections

Loading...

Loading...