10

www.evolutionrage.com

11

www.evolutionrage.com

GETTING STARTED WARNING: Always disconnect the saw from the

power source before making adjustments.

Refer to the “Service Parts Diagram”. Install a blade

as detailed in the “Installing or Removing a Blade”

section.

WARNING: Never start the saw with the cutting

edge of the saw blade in contact with the workpiece

surface. Do not retract blade guard manually. Guard

retracts automatically.

This saw is equipped with an approved cord and

plug for its intended Country of use. Do not alter or

modify the power cord.

Installing or Removing a Blade

WARNING: Only use genuine Evolution blades

which are designed for this machine. Ensure that

the maximum speed of the blade is compatible with

the machine. Only perform this operation with the

machine disconnected from the power supply.

Note: It is recommended that the operator

considers wearing protective gloves when handling

the blade during installation or when changing the

machines blade.

1. Place saw on a level, secure surface.

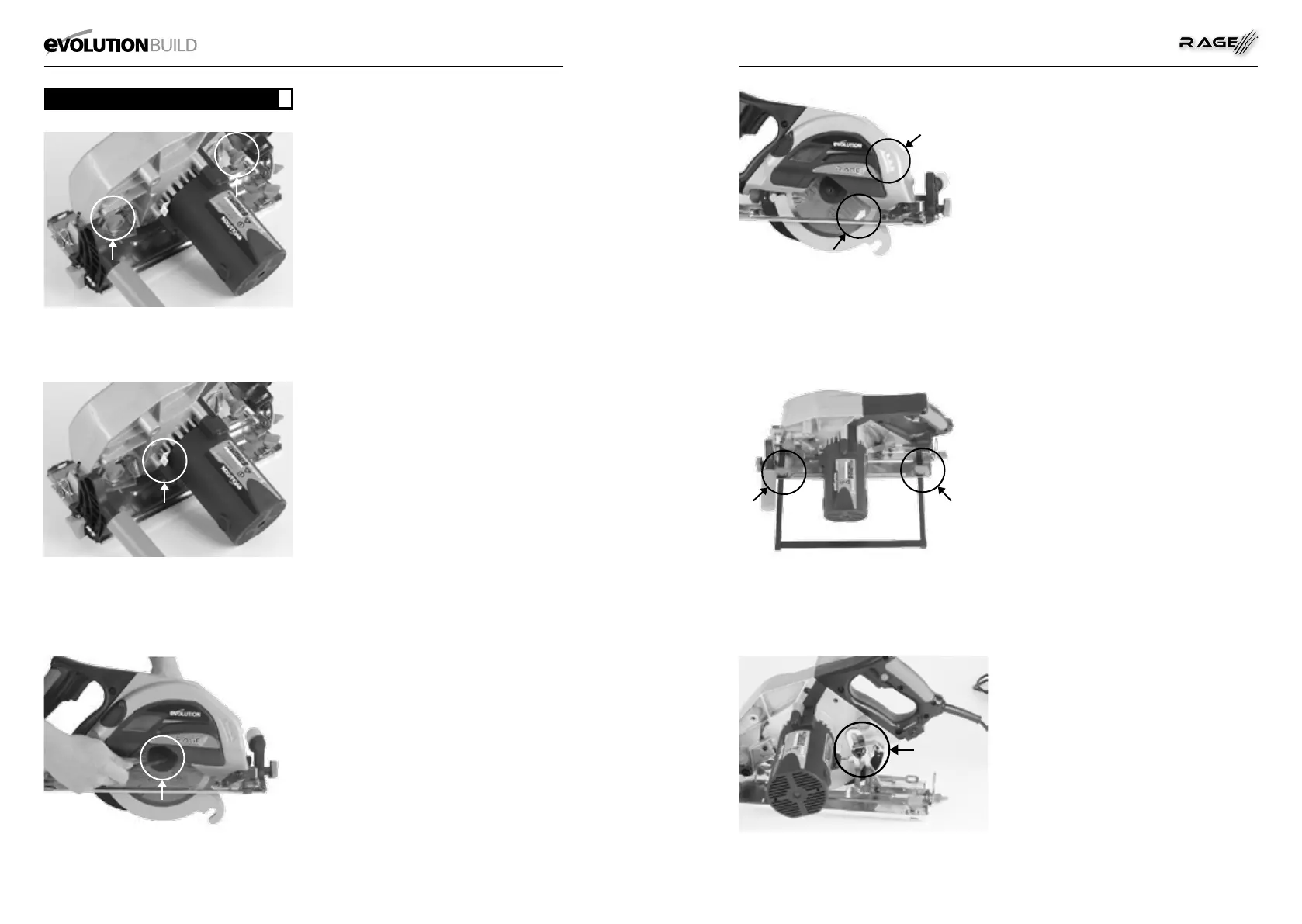

2. Remove the chip collector from the machine by

undoing the (2) large thumb screws. (Fig. 1)

Note: The chip collector thumb screws are ‘captive’

and cannot be removed from the machine.

3. Lock the machine arbor by engaging the arbor

lock. (Fig. 2)

4. Using the supplied Allen Key loosen and remove

the arbor socket headed screw and outer blade

drive ange. (Fig. 3)

5. Remove the saw blade.

6. Thoroughly clean inner and outer blade drive

anges and blade mounting surface before

installing a new blade.

7. Ensure that the direction of rotation arrows

printed on the blade, match the direction of rotation

arrow found on the chip collection cover. (Fig. 4)

8. Reinstall the outer drive ange and the arbor

socket headed screw.

9. Engage the arbor lock and tighten the arbor

socket headed screw securely using the Allen key.

Note : The socket headed arbor screw has a RH

thread.

10. Replace the chip collector and securely tighten

the two thumb screws.

11. Check that the arbor lock is fully released by

manually rotating the blade.

12. Check the operation of the safety guard.

Parallel Edge Guide

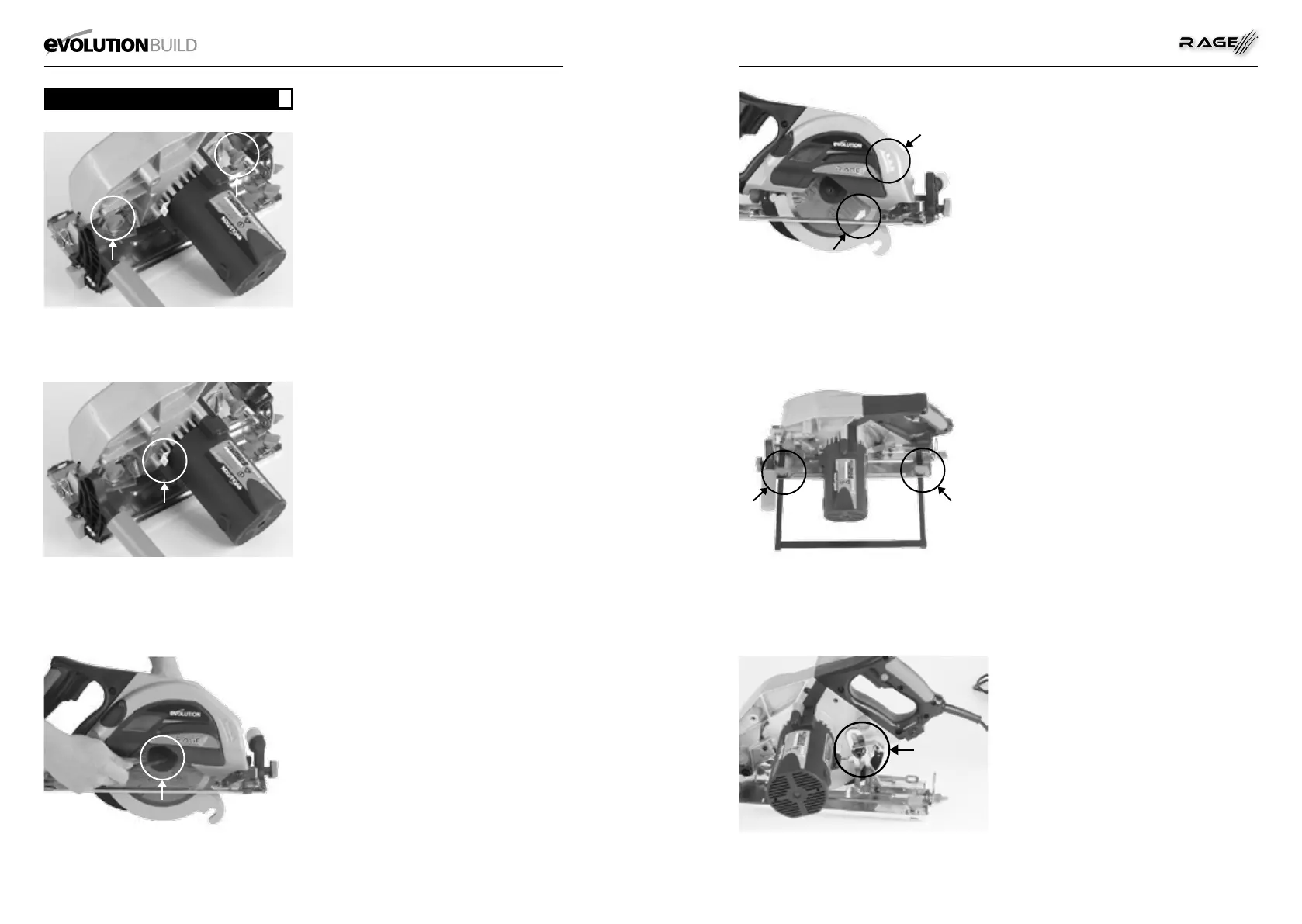

A parallel guide (for help when rip cutting) can be

tted to the sole plate of the machine The guides

arms should be inserted into the rectangular slots in

the turned up edges of the sole plate, and slid under

the locking thumb screws. (Fig. 5)

Note: The edge guide can be tted to either side

of the sole plate and should only be tted and

adjusted with the machine disconnected from the

power supply.

Adjust the edge guide so that it is at the required

distance from the blade and tighten the two thumb

screws. Check that the edge guide is parallel to the

saw blade.

Adjustment of the Cutting Depth

Release the Lever Lock to adjust to the required cutting

depth. In most cases depth should be set at maximum

unless there are obstructions below the work surface.

Tighten the Lever Lock securely to lock in the required

position. (Fig. 6)

Adjustment of the Cutting Angle

1. Loosen the Bevel Locking Screw found at the

front of the saw.

2. Loosen the Rear Bevel Locking Screw found at

the rear of the machines sole plate.

3. Tilt the blade to the required angle. (Fig. 7)

4. Tighten both Bevel Locking Screws securely

Note: An angle scale (0

O

-45

O

) is incorporated into

the Bevel Locking quadrant to aid setting.

Operating Advice

Carry out routine safety checks each time you

use the machine. Check that all safety guards are

operating correctly, and that all adjustment handles/

screws are tightened securely.

Check that the blade is secure and installed

correctly. Also check that it is the correct blade for

the material being cut.

Check the integrity of the power cord.

Always clamp the workpiece to a rigid support such

as a bench or saw horse whenever possible.

GETTING STARTED

GB

FIG 1

FIG 2

FIG 3

FIG 4

FIG 5

FIG 6

Loading...

Loading...