IONPURE

®

LX CEDI Modules

Page 21 IP-MAN-LX-1220-EN.pdf

5. START-UP PROCEDURE

5.1. Test Interlocks

· Test flow switches and other interlocks, including the RO interlock if applicable

· Test pressure relief if applicable

· Set alarm points

5.2. Startup of LX Modules

· Make sure that modules are correctly connected to the DC power source.

· Make sure that the LX product line is directed to drain.

· Turn on the feedwater. Adjust pump and/or valves to obtain the desired flows and

pressures in the product and reject streams. The reject flow is typically set at about

11% of the product flow (this gives a water recovery of 90%). See Section 5.4, below.

· Valves are adjusted so the product outlet pressure is about 2 to 5 psig (0.1 to 0.3 bar)

higher than the reject outlet pressure at the desired flow rates.

· Adjust the DC power supply to the current setting determined in section 4.2.

· Test all flow switches and interlocks to ensure LX DC power is shut off when flow is

interrupted.

· Continue to direct the product water to drain until it reaches the desired quality.

· Once product reaches the desired quality, connect to process. Readjust pressures as

required to maintain product outlet pressure 2 to 5 psi (0.1 to 0.3 bar) above the reject

outlet pressure.

· Record operating data daily on suitable log sheet (see example in section 7.0). The

CEDI system should achieve steady-state operation in a few days,

5.3. Minimum Reject Flow Rate

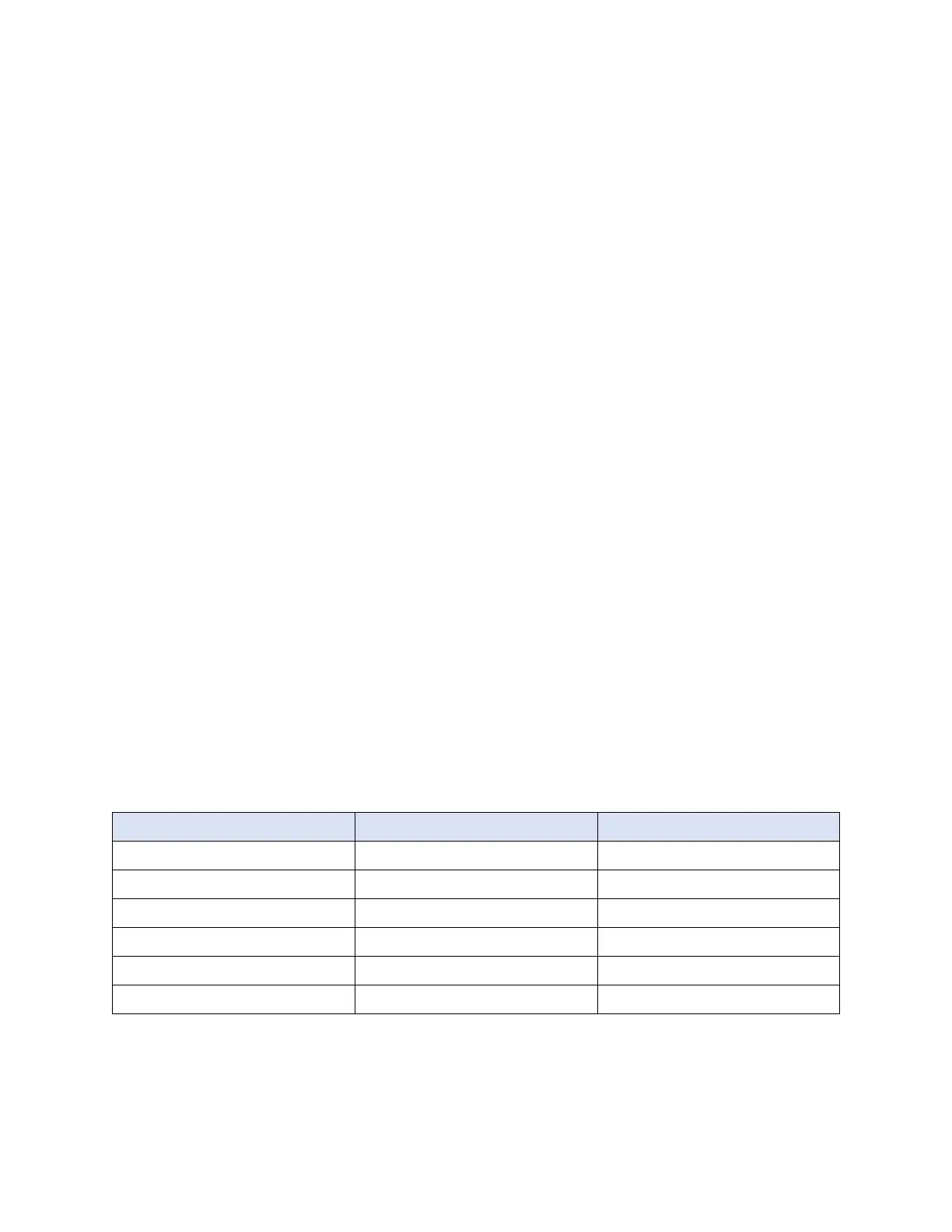

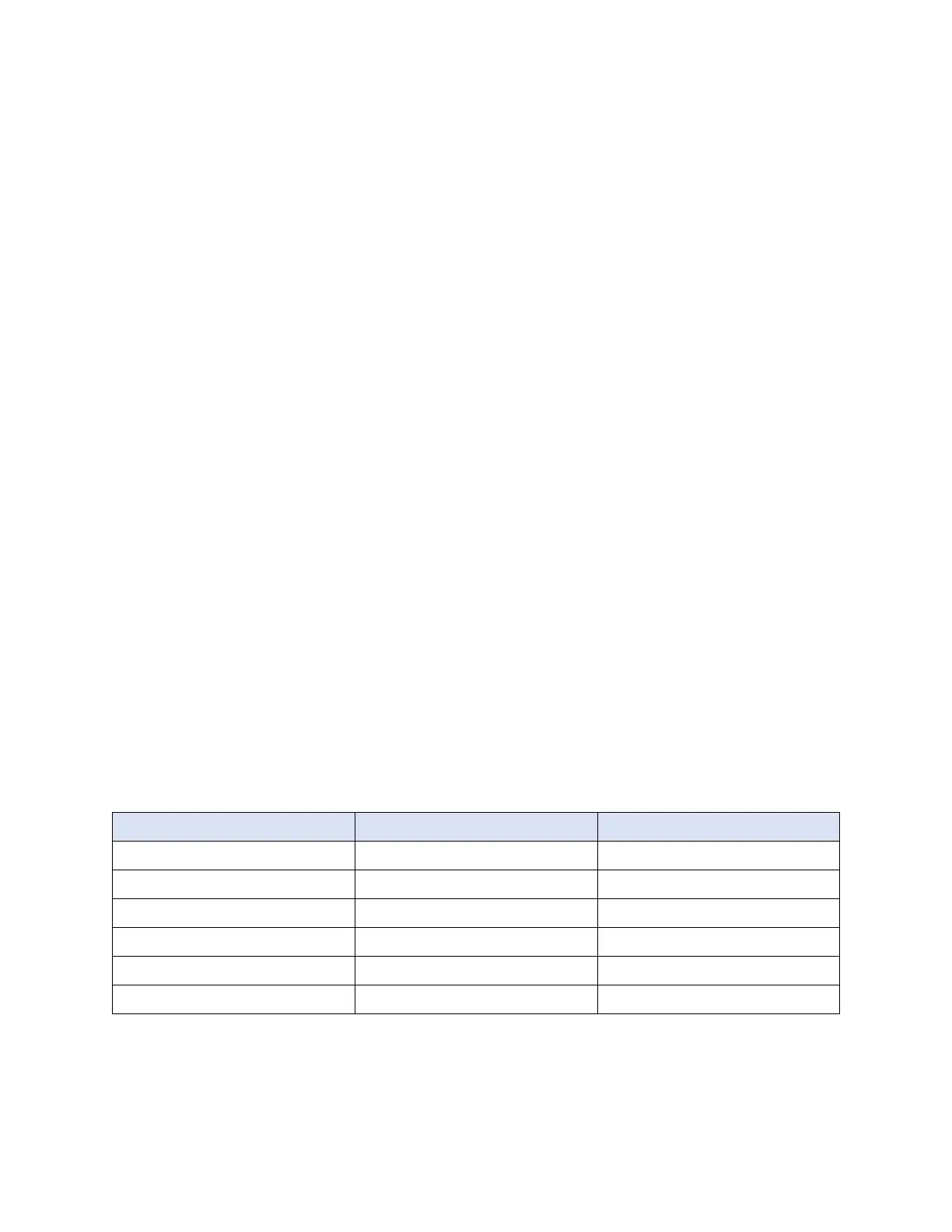

Table 5-1 Minimum Reject Flow Rates for Various LX Module Sizes

Module Size gpm L/min

IP-LXM 04 0.07 0.26

IP-LXM 10 0.16 0.61

IP-LXM 18 0.27 1.02

IP-LXM 24 0.36 1.36

IP-LXM 30 0.44 1.67

IP-LXM 45 0.66 2.50

5.4. Water Recovery

· Percent water recovery = (100)(product flow)/(product flow + reject flow)

Loading...

Loading...