Page 2 of 4

109-2027 Rev. A

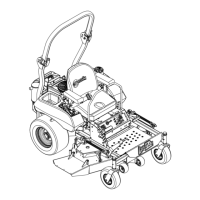

Figure 2

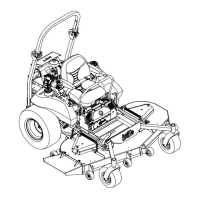

Figure 3

10. LOOSELY install lower roll bar hardware (four 3/8-

16 x 1 capscrews, four spring disk washers and

four 3/8-16 whizlock nuts) to the tubes on each

side. (Fig. 2).

Note: Be sure the spring disk washer cone is

installed towards the head of the capscrew.

11. For units with Kohler engines, secure oil drain

hose assembly to left-hand lower roll bar bracket

with 24” long plastic tie supplied (Fig 2). Clip off

excess tie.

12. Locate the latch pin assemblies (pin and hairpin

connected with a lanyard).

13. Insert a 1/2-13 x 3 1/4 capscrew (removed in step

5) into the bent tab washer on the lanyard of each

pin assembly (Fig. 3).

Note: Make sure the bent tab in the washer is

towards the head of the bolt.

14. Lightly oil the inside surfaces of the ear-shaped

plates at the upper end of the lower roll bar tubes

(Fig. 3).

15. Locate the upper u-shaped section of the roll

bar. Install the upper roll bar section using the

two 1/2-13 x 3 1/4 capscrews and two 1/2-13

hex flange lock nuts (removed in step 5). Do

not over tighten. Make sure upper roll bar can

pivot freely.

Notes:

• Make sure the capscrew and nuts are

installed with the nut to the inside of the roll

bar.

• Make sure the tab on the lanyard washer is

installed as shown and points toward the

front of the unit.

16. Raise the roll bar into the upright position and

secure with the latch pin assemblies on each

side. Install latch pin from outer surface of roll

bar assembly and secure with the hairpin to the

inside.

17. Torque all lower roll bar hardware attached to

the machine frame to 30 ft-lbs. (41-47 N-m).

18. Tighten the front knobs against the upper roll

bar ends.

Installing the Drive Wheels

1. Remove the 1/2-20 drive wheel nuts (installed

on studs of drive motors; See Fig. 2) and retain

for wheel mounting. Remove and discard

shipping brackets mounted on wheel hubs.

2. Mount drive wheels with the valve stem to the

outside of the unit. Secure using four (4) 1/2-20

wheel nuts removed in step 1.

3. Torque to 95 ft-lbs (128 NxM).

Checking Tire Pressure

1. Check the tire pressure in the drive tires. Proper

inflation for drive tires is 13 psi (90 kPa).

2. Adjust if necessary.

Servicing the Battery

The machine is shipped with a filled lead

acid battery.

1. Unhook seat latch and tilt seat up to gain access

to the battery.

Battery posts, terminals, and related

accessories contain lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash

hands after handling.

FOR KOHLER UNITS,

SECURE OIL DRAIN

HOSE IN THIS AREA

Loading...

Loading...