Maintenance

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecouldseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Also

pushthewire(s)asidesoitdoesnotaccidentally

contactthesparkplug(s).

WARNING

Theenginecanbecomeveryhot.Touchingahot

enginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheenginearea.

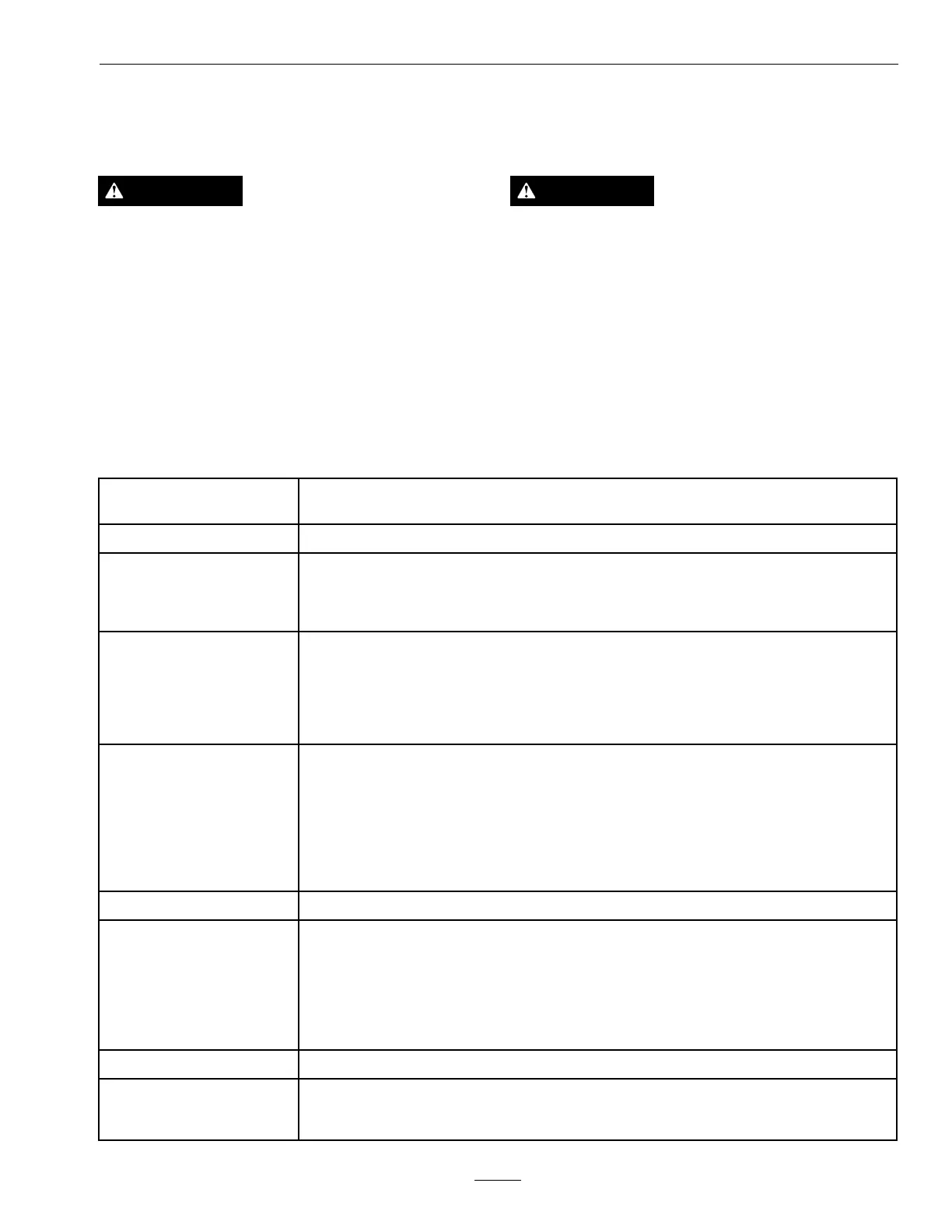

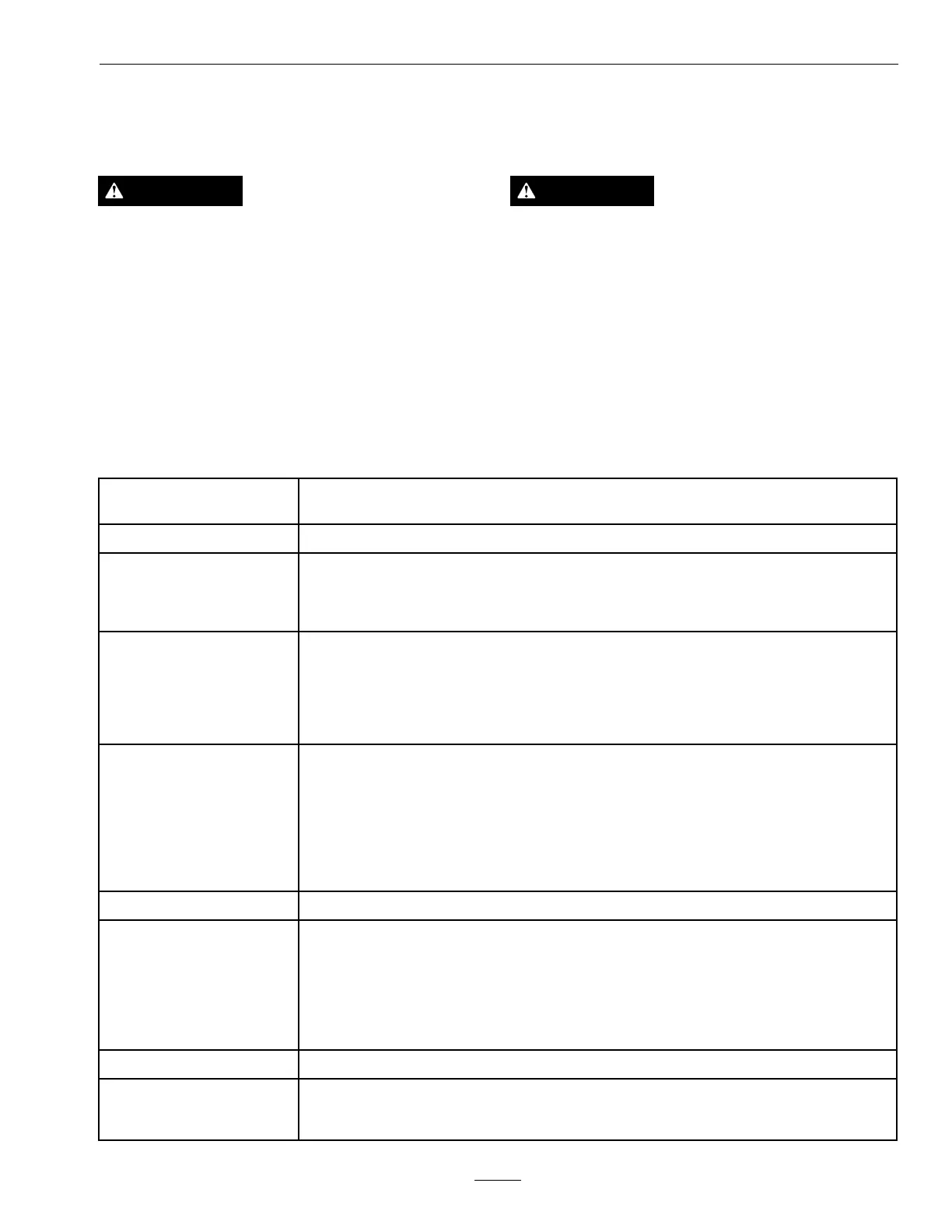

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst5hours

•Changetheengineoil.

Aftertherst100hours

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethehydraulictransmissionlteranduid.

•Checkthewheelhubandtransmissionoutputshaftnuttorquespecication.

•Checkthewheellugnuts.

Beforeeachuseordaily

•Checktheengineoillevel.

•Checkthetines.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Cleantheengineandexhaustsystemarea.

•Cleanthegrassanddebrisbuild-upfromthemachine.

Every50hours

•Checktheauxiliaryhydraulicoillevel.

•Checkthehydraulictransmissionoillevel.

•Checkthetirepressures.

•Checktheconditionandtensionofthebelts.

•Checktheconditionofthechains.

•Checktheconditionofthesprockets.

•Lubricatethechains.

•Checksparkarrester(ifequipped).

Every80hours

•Removeengineshroudsandcleancoolingns.

Every100hours

•Changetheengineoil.(Mayneedmoreoftenundersevereconditions.)

•Greasethejackshaftbearings.

•Greasethewheelbearings.

•Greasetineshaftbearings.

•Greasetineassemblyidlers.

•Greasecontrolpivots.

•Greasebeltidlerpivot.

Every160hours

•Checkthesparkplugs.

Every250hours

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;replaceif

dirty.(Mayneedmoreoftenundersevereconditions.SeetheEnginemanualforadditional

information.)

21

Loading...

Loading...