Maintenance

Adjustments

Note:Shutoffengine,waitforallmovingpartsto

stop,engageparkingbrake,andremovekeybefore

servicing,cleaning,ormakinganyadjustmentsto

theunit.

CAUTION

Raisingtheunitforserviceormaintenance

relyingsolelyonmechanicalorhydraulic

jackscouldbedangerous.Themechanicalor

hydraulicjacksmaynotbeenoughsupportor

maymalfunctionallowingtheunittofall,which

couldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstandsor

equivalentsupport.

AuxiliaryPumpDriveBelt

Adjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Totightenbelt,loosenthe3/8inchnylocnuton

auxiliarypumpbeltidlerpulley.Slideboltinward

inslotandretightennylocnut.

3.Whenproperlyadjusted,thebeltshouldhave1/2

inch(1.3cm)ofdeectionwiththreepoundsof

pressureonthebeltmidwaybetweentheauxiliary

pumpandenginepulley.

TransmissionDriveBelt

TensionAdjustment

•CheckingExistingBelt:

1.Stopengine,waitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

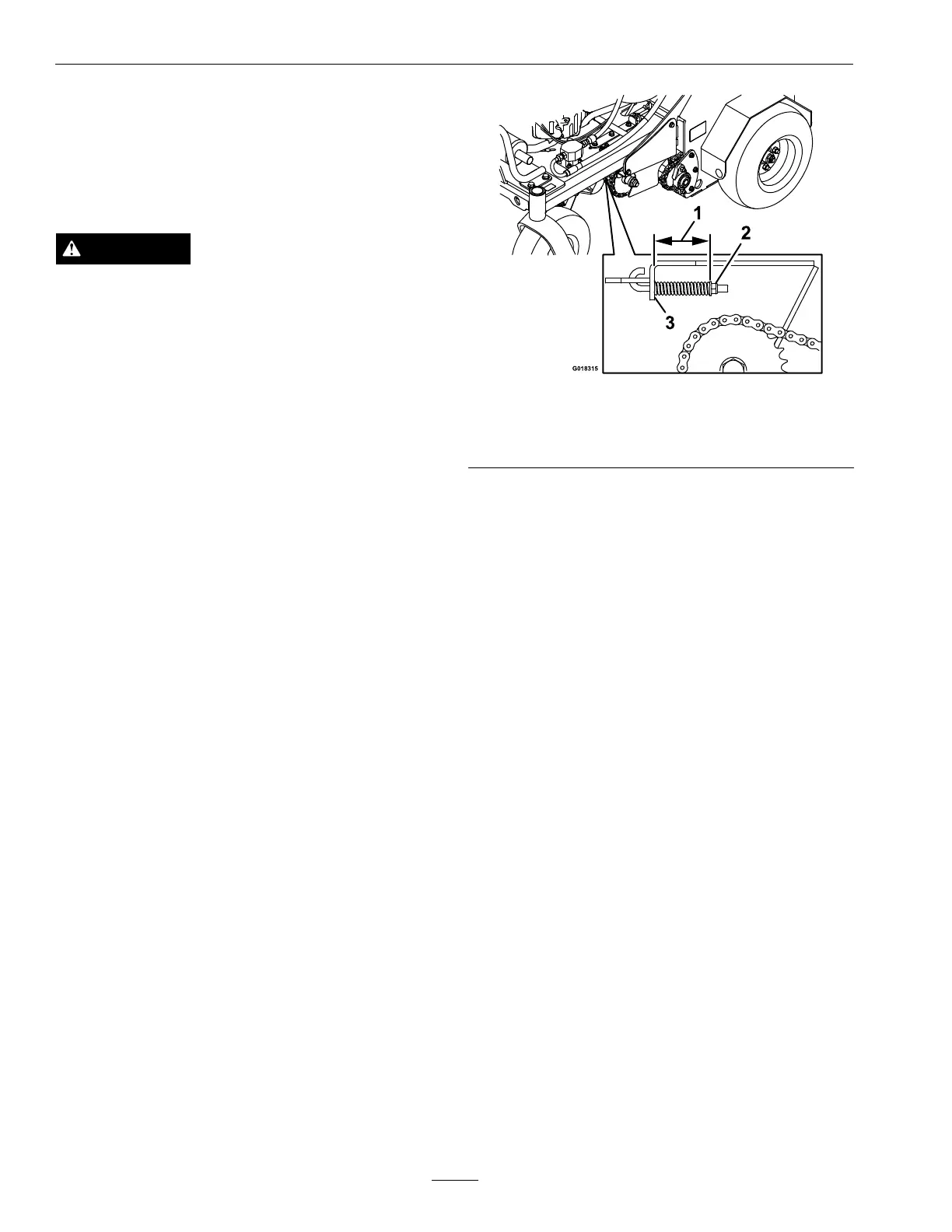

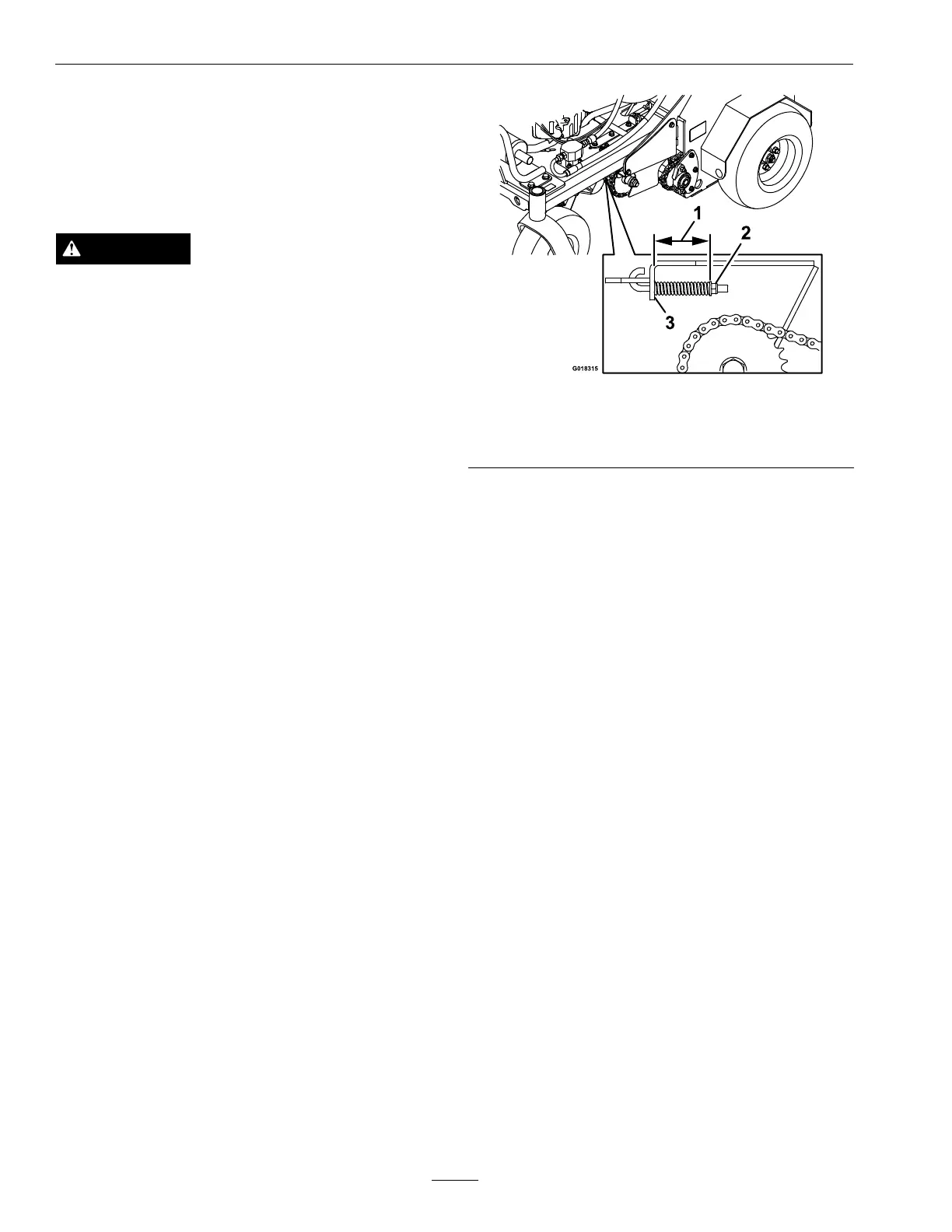

2.Measurethespringlengthfrominsidethe

idlerbrackettotheinsideoftheangednut

asshowninFigure12.

Figure12

1.Measurespringlength3.Idlerbracket

2.Flangednut

3.Adjustthenutuntilthespringlengthmeasures

25/8to23/4inches(67–70mm)maximum.

•InstallingaNewBelt:

1.Stopengine,waitforallmovingpartstostop,

andremovekey.Engageparkingbrake.

2.Installthenewbelt.

3.Measurethespringlengthfrominsidethe

idlerbrackettotheinsideoftheangednutas

shownin

Figure12.Setthespringlengthto

23/8inches(60mm).

4.Starttheengineandallowthemachinetorun

for30seconds.

5.Stopengine,waitforallmovingpartstostop,

andremovekey.

6.Checkthespringlengthandadjustthe

nutuntilthespringmeasures23/8inches

(60mm).

JackshaftDriveChain

TensionAdjustment

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lifttherearoftheunitandsupportusingjack

standsorequivalentsupport.

3.Checkthechainsonbothsidesoftheunitfor

propertension.Thechainsshouldbeableto

moveupanddown1/2-3/4inch(12-19mm).

4.Loosenthehydromountingboltsandslideto

adjustthetension.

30

Loading...

Loading...