1 3

EXPERT Manual

The final step in your flight pack installation will be to determine the

amount each control surface will move on your model at full transmit-

ter stick deflection. Please refer to your aircraft’s instruction manual

for suggested travel limits.

It is possible to increase/decrease the amount that your control surface

moves at full stick deflection by mechanical adjustments.

It is imperative that the servo does not attempt to push/pull the con-

trol surface past its mechanical limits. This condition is called “binding.”

When a servo moves a control surface into a “binding” position, the

servo itself then becomes “stalled,” unable to reach its full deflection.

This condition is both harmful to your control linkage and to your

servo. This “stalled” condition will also force the servo to drain power

more quickly from your flight pack battery, thereby reducing your

usable flying time. Fortunately, servo “stalling” is usually easy to

detect by either a “buzzing” or “humming” sound which comes from

the stalled servo.

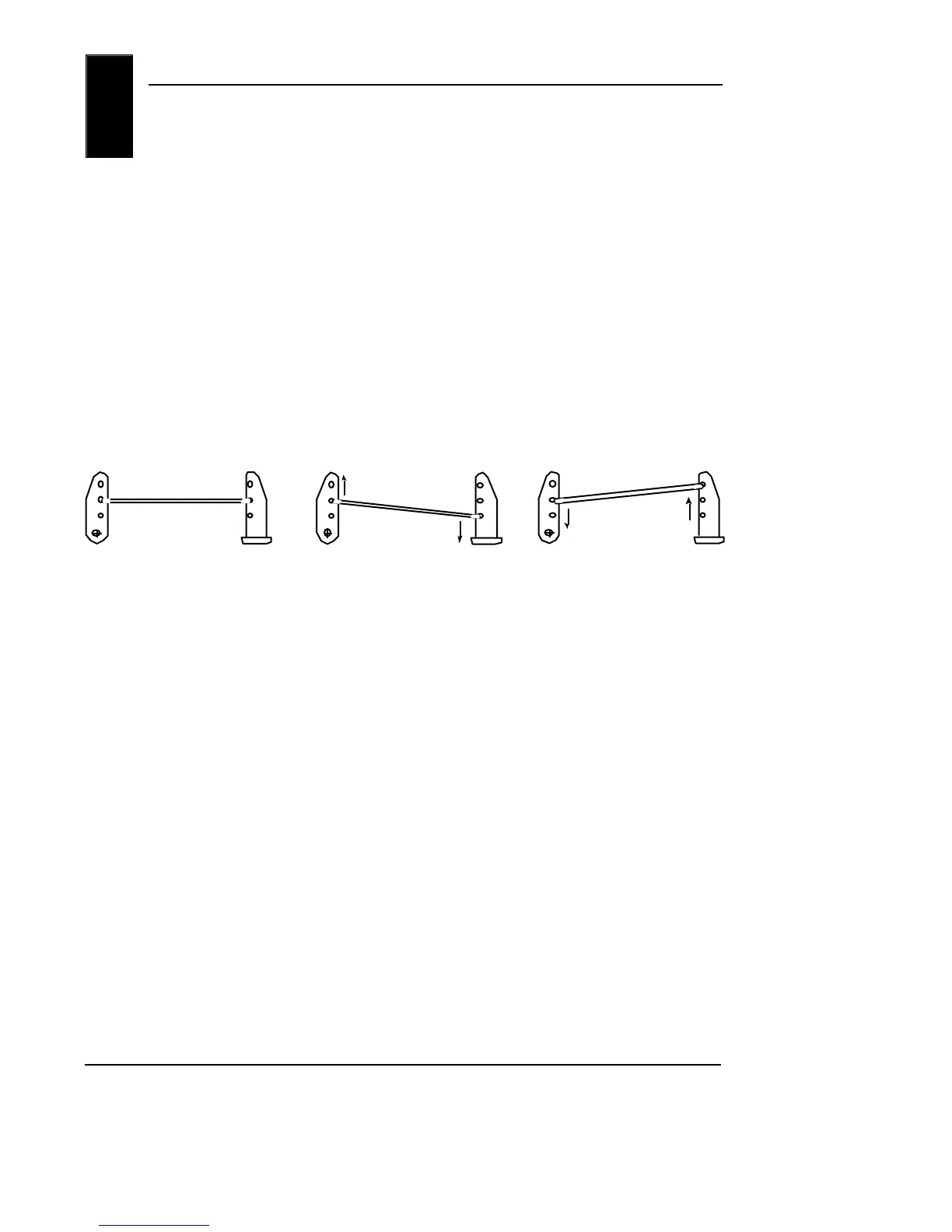

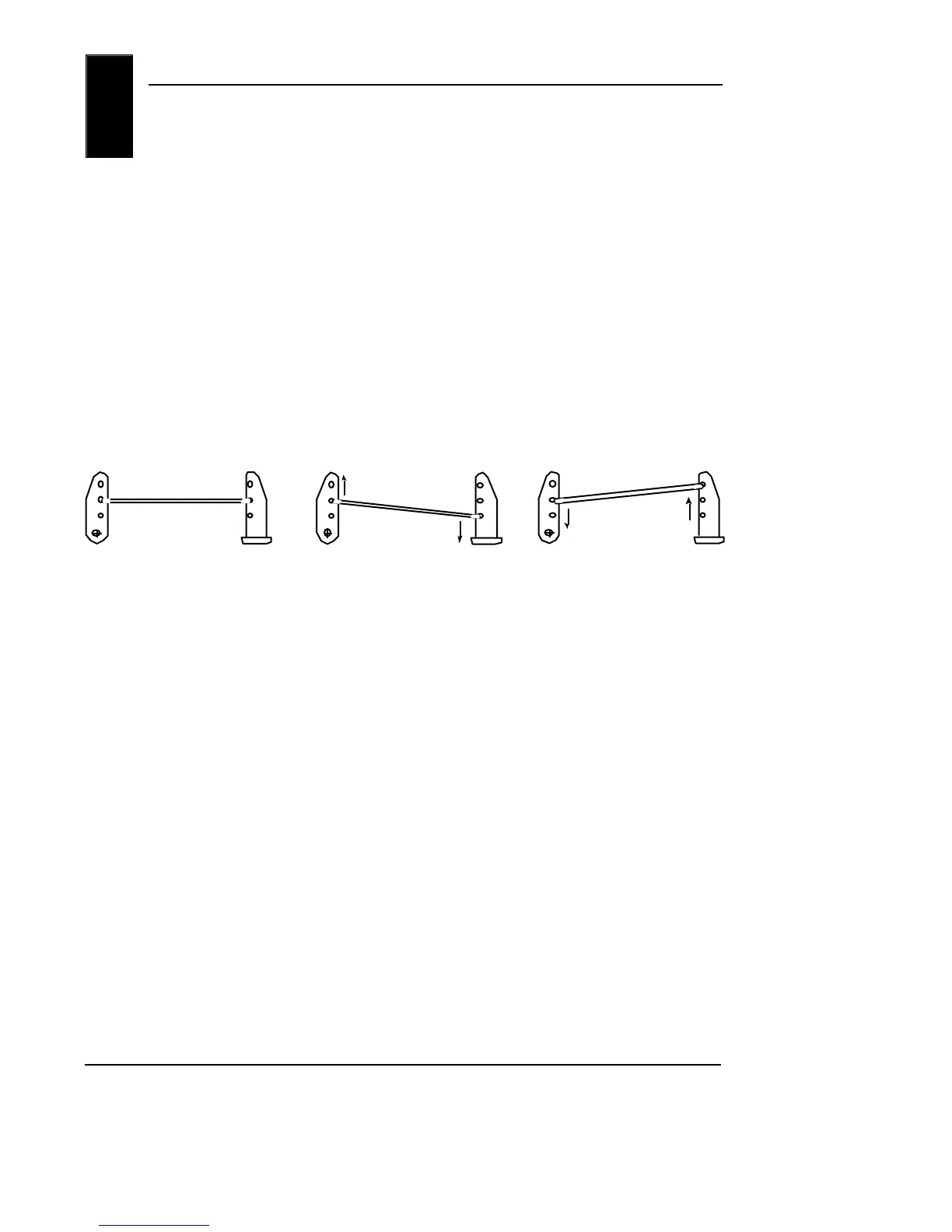

The following diagram is designed to help clarify how to increase or

decrease control surface travel mechanically to eliminate control sur-

face “binding” and servo “stalling”.

To increase control surface travel, select a linkage attachment point fur-

ther outward on the servo arm or further inward on the control horn

closer to the control surface (Figure 2).

To reduce control surface travel, select the linkage attachment point

close to the center of the servo area or further out on the control horn

on the control surface (Figure 3).

Quite simply, by moving the control rod in on the servo arm/wheel,

control surface travel will be reduced, and by moving the control rod

out on the servo arm, the control surface travel will be increased. The

opposite holds true for the control surface arm (horn) as well. You may

also use any combination of these positions to achieve proper control

surface/servo travel.

NOTE:Once the appropriate servo arm/wheel and control rod location

has been established, be certain that you have secured the

servo arm to the servo output shaft using the original servo

horn screw.

Control Rod

Figure 1 Normal (Linear)

Linkage Set Up

Figure 2 Increased Control

Surface Movement

Figure 3 Reduced Control

Surface Movement

Servo Arm

Control Surface Arm

(Horn)

Control Surface Arm

(Horn)

Control Surface Arm

(Horn)

Servo Arm Servo Arm

Control Rod

Control Rod

ADJUSTING CONTROL SURFACE TRAV E L

9.3

Loading...

Loading...