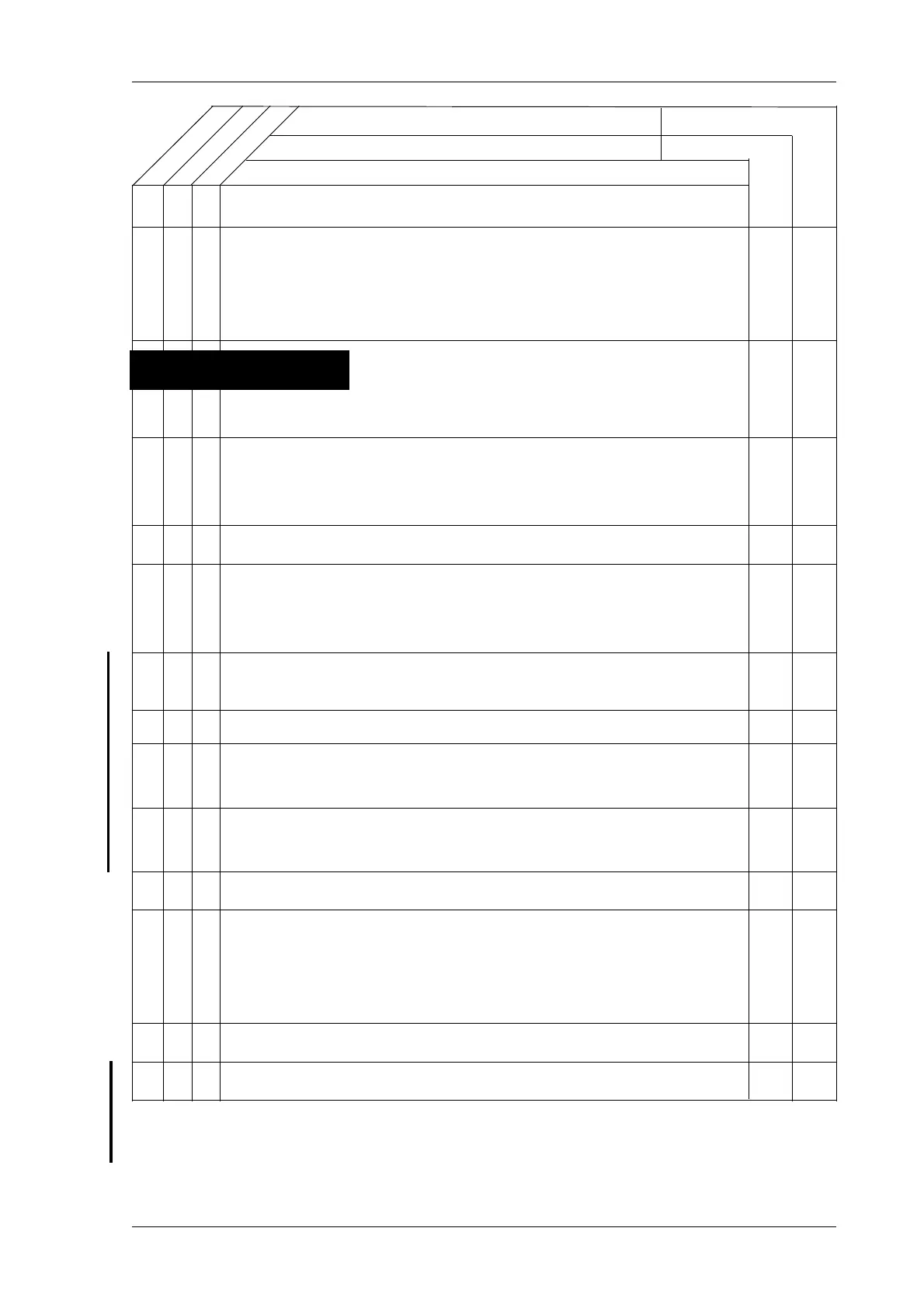

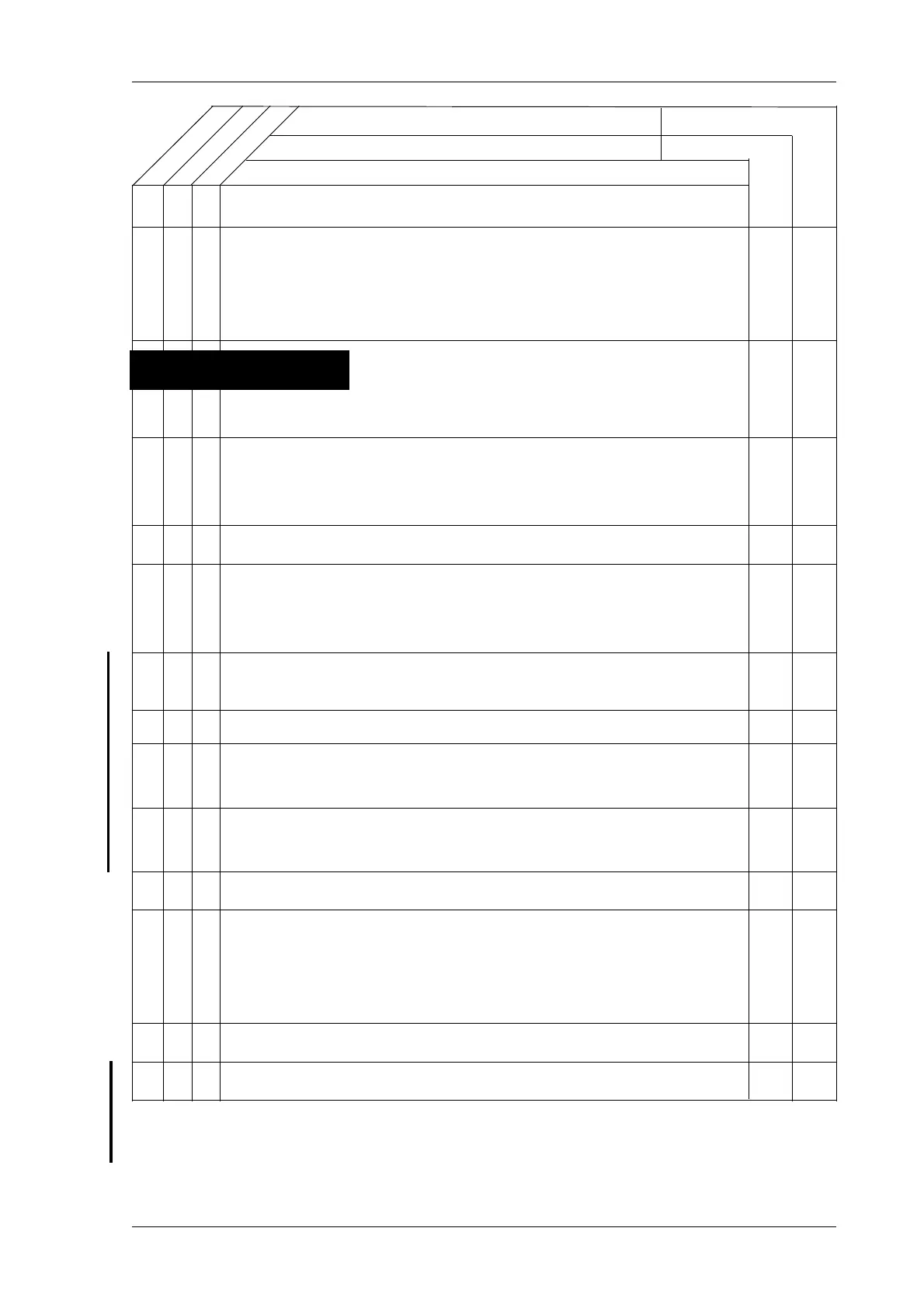

EXT

RA - FLUGZEUGBAU GmbH

SERVICE MANUAL EXTRA 200

CHAPTER 05

PAGE 12

PAGE DATE: 1. July 1996

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

Engine compartment

(Refer to latest edition of Textron Lycoming Operator's

Manual and SB's, of Christen Product Manual 801 Series and

SB's and of Slick Magneto Maintenance and Overhaul Manual

and SB's)

Ground magneto primary circuit before

working on engine

O O 1 Remove engine cowling.

O O 2 Inspect cowling and air inlet screen for damage, cracks,

distortion, overheated areas and loose or missing blind nuts

and secure attachment of oil level access plate.

O O 3 After this inspection clean cowling.

O O 4 Check fire protection paint. If necessary repaint the fire

protection paint ("WIEDOFLUGAT" Brandschutzfarbe N

56582 / T508).

O

1

O O 5 Drain oil sump in accordance with Chapter 12-10-04 En-

gine Oil Replenishing

O

1

O O 6 Clean and inspect oil screen filter

O

1

O O 7 Clean suction oil strainer at oil change (check strainer for

foreign particles).

O

2

O O 8 Change full flow (cartridge type, AEIO-360-A1E type en-

gine) oil filter element (check element for foreign particles).

O 9 Inspect oil temperature sender unit for leaks and security.

O O 10 Inspect flexible oil lines, oil return lines and fittings for leaks,

security, chafing, dents, and cracks (ref: FAA AC 43.13-1A).

Replace flexible oil lines at engine TBO per Lyc. SB 240.

Check condition of fire sleeves.

O 11 Clean and inspect oil radiator and attachment.

O

3

12 Remove and flush oil radiator.

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

D A N G E R

1 at 10 and 25 hours and then each 25 hours

2 at 10 and 25 hours

3 each 500 hours

PAGE DATE: 15. December 1999

Loading...

Loading...