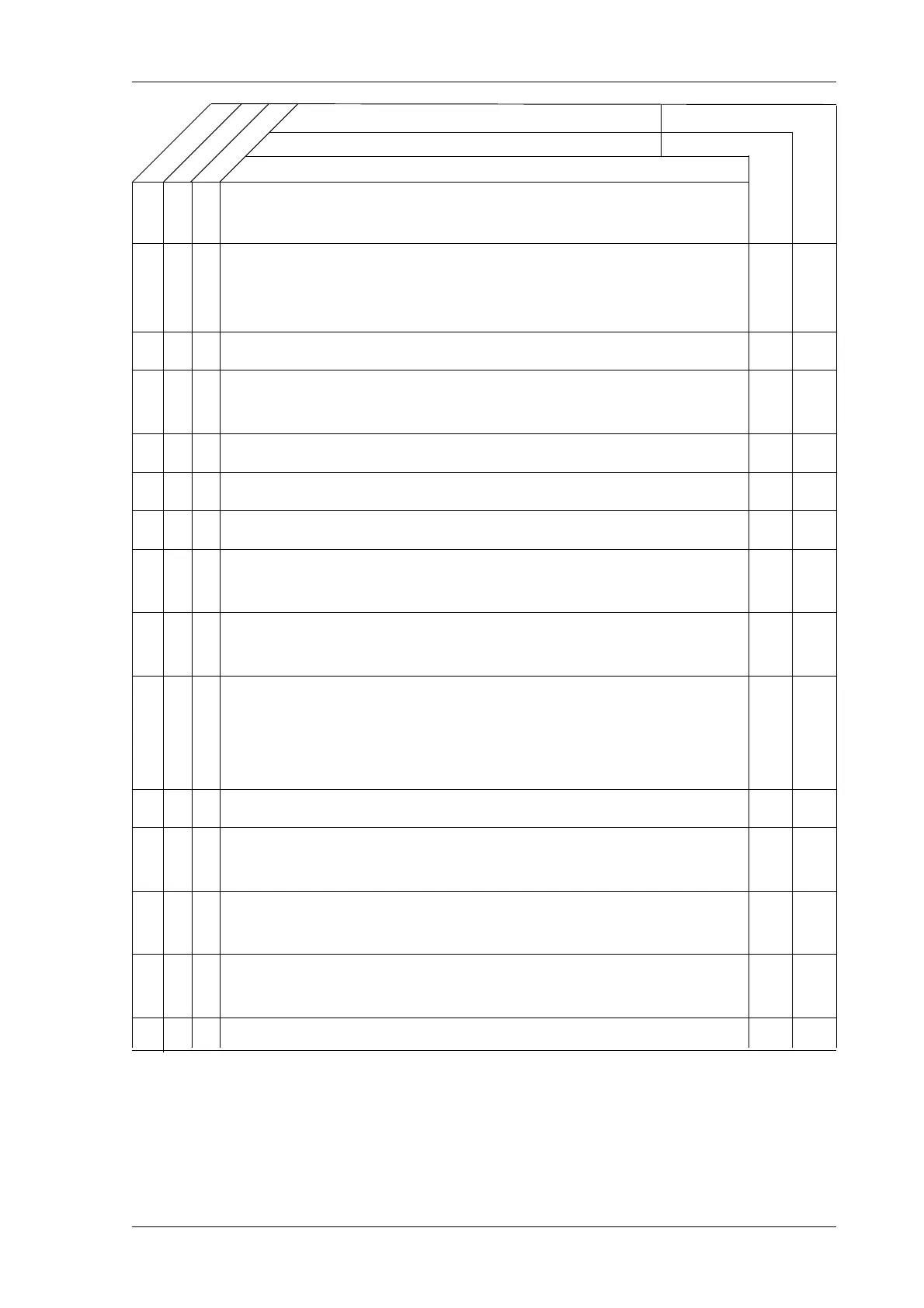

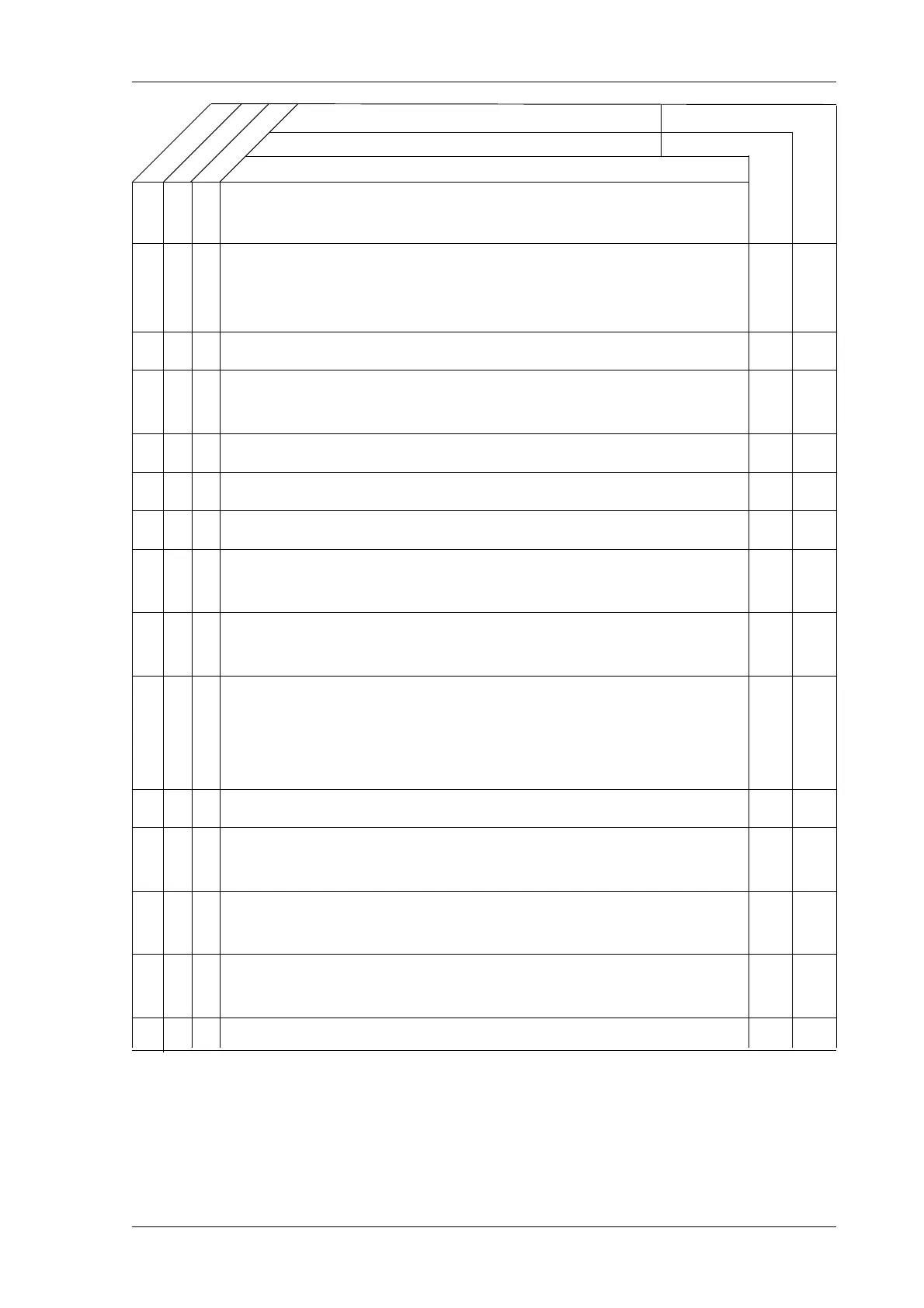

EXT

RA - FLUGZEUGBAU GmbH

SERVICE MANUAL EXTRA 200

CHAPTER 05

PAGE 14

PAGE DATE: 1. July 1996

O 24 Adjust magneto to engine timing, refer to Slick Magneto

Maintenance and Overhaul Manual

O 25 Inspect wiring connections, vent holes and P-lead

attachment, refer to Slick Magneto Maintenance and Over-

haul Manual.

O

1

26 Clean magnetos.

O

1

27 Inspect ball bearing assembly, impulse coupling, coil, con-

tact points, condenser and carbon brush.

O

2

28 Replace ball bearings.

O

1

29 Lubricate magnetos.

O

3

30 Overhaul or replace magnetos.

O 31 Check fuel injector for general condition, clean fuel inlet

screen.

O O 32 Inspect intake seals and O-rings for leaks and clamps for

tightness.

O O 33 Inspect flexible fuel lines, fuel injection lines and fittings for

leaks, security, chafing, dents, and cracks (refer to Lycoming

SB 342 each 100h; replace or overhaul as required or at

engine overhaul). Check condition of fire sleeves.

O O 34 Check fuel system for leaks.

O

4

O O 35 Remove, clean and inspect gascolator screen and fuel filter

bowl.

O O 36 Inspect throttle, mixture, and propeller governor controls for

security, travel, and operating conditions.

O O 37 Inspect exhaust stacks, connections and gaskets (replace

gaskets as required).

O O 38 Inspect exhaust slip joints for general condition.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

1 each 500 hours

2 each 1000 hours

3 together with engine

4 clean at least every 90 days

Loading...

Loading...