Maintenance - RT17, RT19 Tedder

41

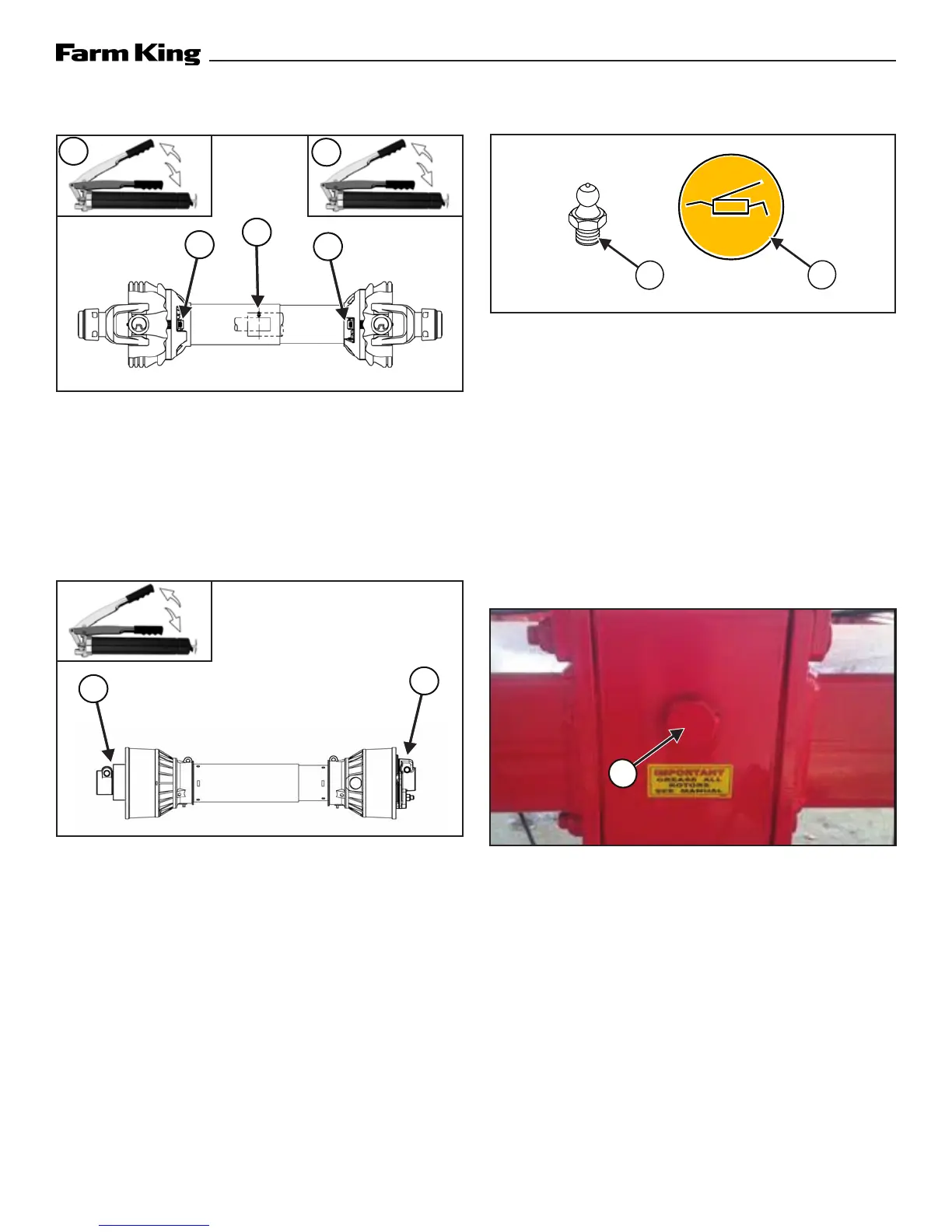

Figure 23

Apply two pumps of grease to the guard bushings

(Item 1) [Figure 23].

Apply eight to ten pumps of grease to the

telescoping member (Item 2) [Figure 23].

Grease every 50 hours.

Figure 24

Apply two pumps of grease to the slip clutch (Item

1) [Figure 24] and PTO quick disconnect (Item 2)

[Figure 24].

Grease every 50 hours.

1

1

2

2

8-10

1 2

1

2

2

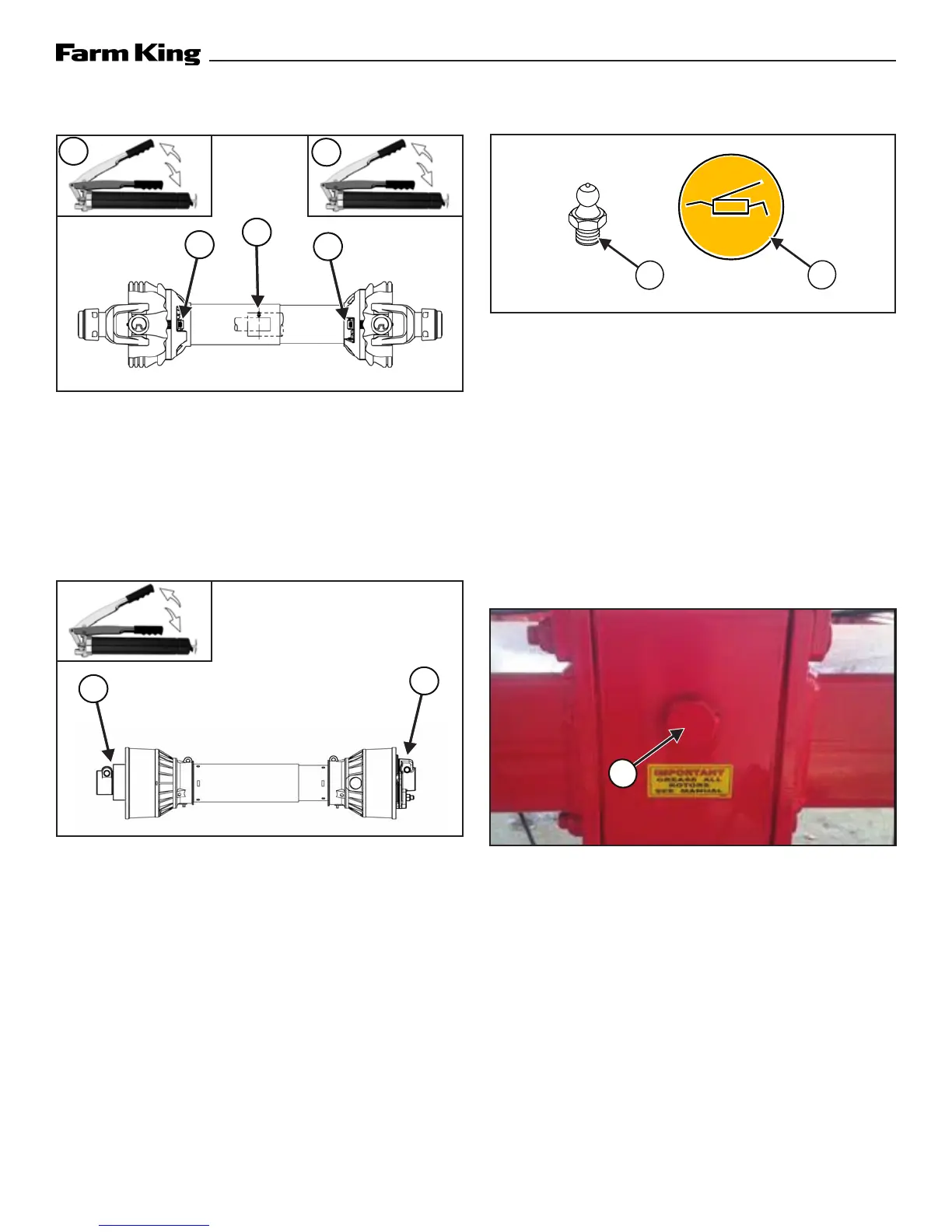

Figure 25

Lubrication point locations (Item 1) are identified

with a sticker (Item 2) [Figure 25].

Lubrication points include:

• Wheels

• Driveline mounts

• Hitch pivot points

• Wing pivot points

Grease every 50 hours.

Figure 26

Check the grease in the transfer box (Item 1).

Internal components must be immersed in grease

[Figure 26].

Use grease type: AGIP GREASE MU EP2

Grease type equivalents:

• ISO L-X-BCHB 2

• DIN 51825 KP2K-20

• CINCINNATI MILACRON P-64

Check / fill grease in gearbox every 100 hours.

2

1

1

Loading...

Loading...