MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 44 -

Pump Assembly Continued

.125

3.18

.125

3.18

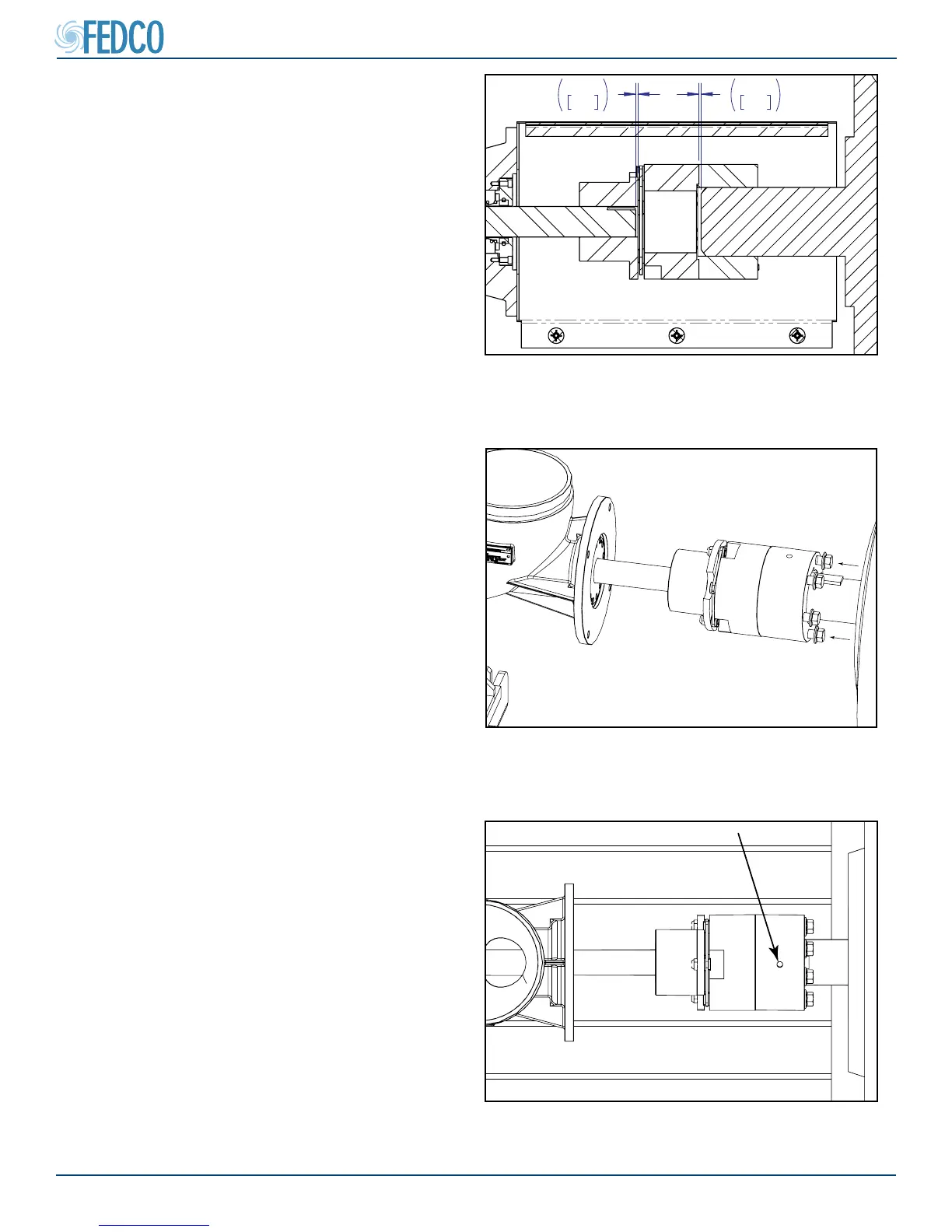

Figure 84 - Installing Dropout Coupling Set

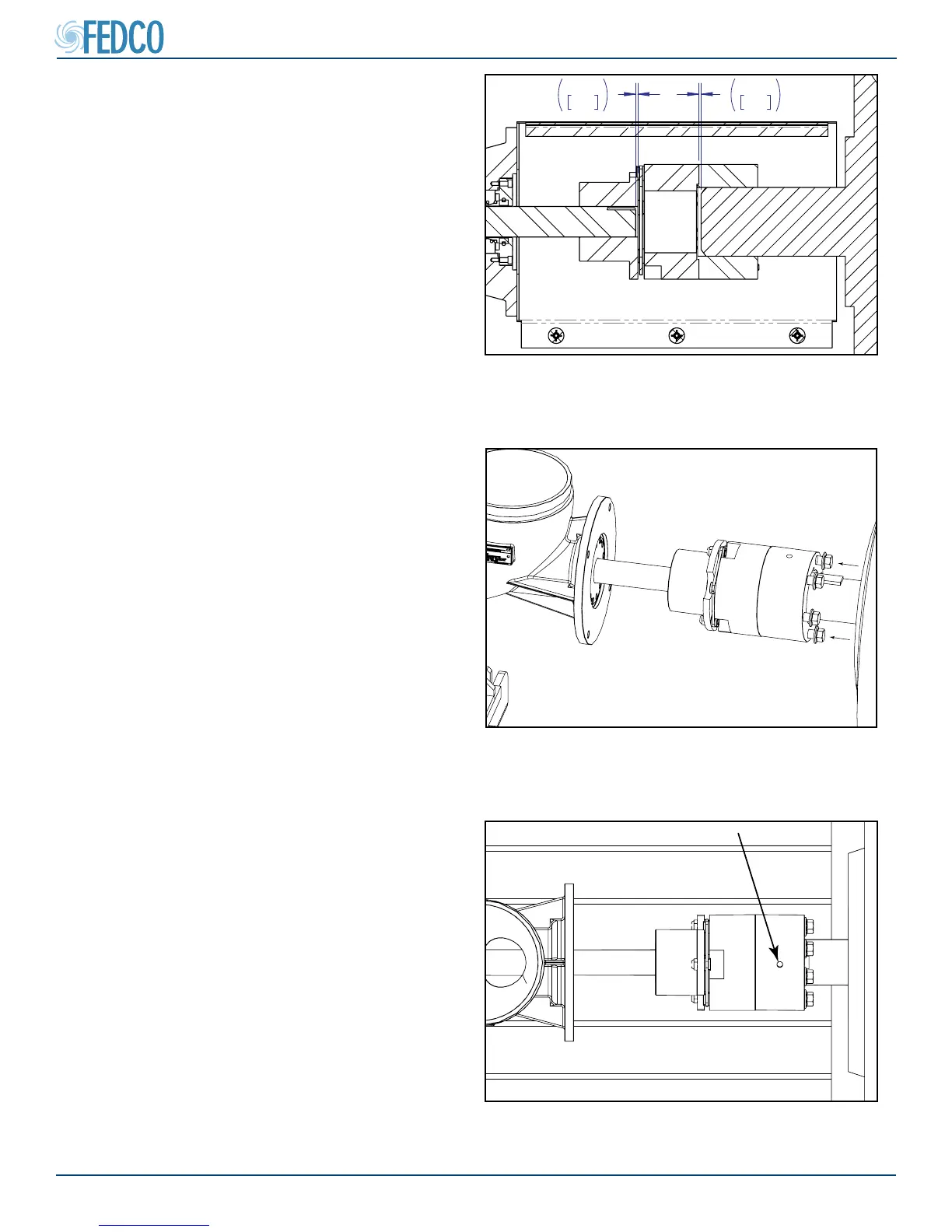

Screw

Figure 83 - Joining Coupling Hubs

Figure 82 - Dropout Coupling Cross Section

14. Install the dropout coupling set screw and

tighten to torque specs found in the Fas-

tener Torque Specications section of this

manual.

NOTES: Set screws are only on the motor side

of the dropout coupling. NO set screws should

be installed on the pump shaft side of the cou-

pling.

13. Join the motor hub with the dropout hub us-

ing hardware removed in step 2.

NOTES: If indicating pump using the Reverse

Indicator or a Laser Alignment Tool Method,

tighten dropout coupling set screw and initiate

alignment process. Upon completion, remove

coupling and alignment bushing as described

in step 1. Re-install dropout coupling and pro-

ceed with next step.

NOTES: Remove alignment bushing before

operation.

NOTES: Cross section for reference only.

Loading...

Loading...