MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 6 -

Unpacking/ Inspection/ and Storage Continued

Pump Storage Requirements

• The MSD unit must be protected from

moisture, sand, grit, and other foreign mat-

ter. Do not remove the protective covers

from the pipe connections until ready to in-

stall. For long-term storage, keep pump and

all other components in its original crate

away from moisture, sand or dust.

Long-Term Storage (>6 Months) Checklist

1. Check caps to ensure they have not been

damaged or allowed debris inside the unit.

• Check for debris (wood, slag, sand or any

dirt) and clean up with a clean, wet rag if

minor.

2. Shaft Check:

• Turn manually (through feed inlet) and

check for ease of turning.

• Check for axial movement.

3. Seal Check:

• Prime MSD with clean water and allow the

O-rings to soak for 1 hr before start-up.

Check for leaks.

Motor Storage Requirements

• Specic conditions are required for proper motor care and storage. Refer to the motor manu-

facturers instructions for specic steps and instructions.

Pre-Installation

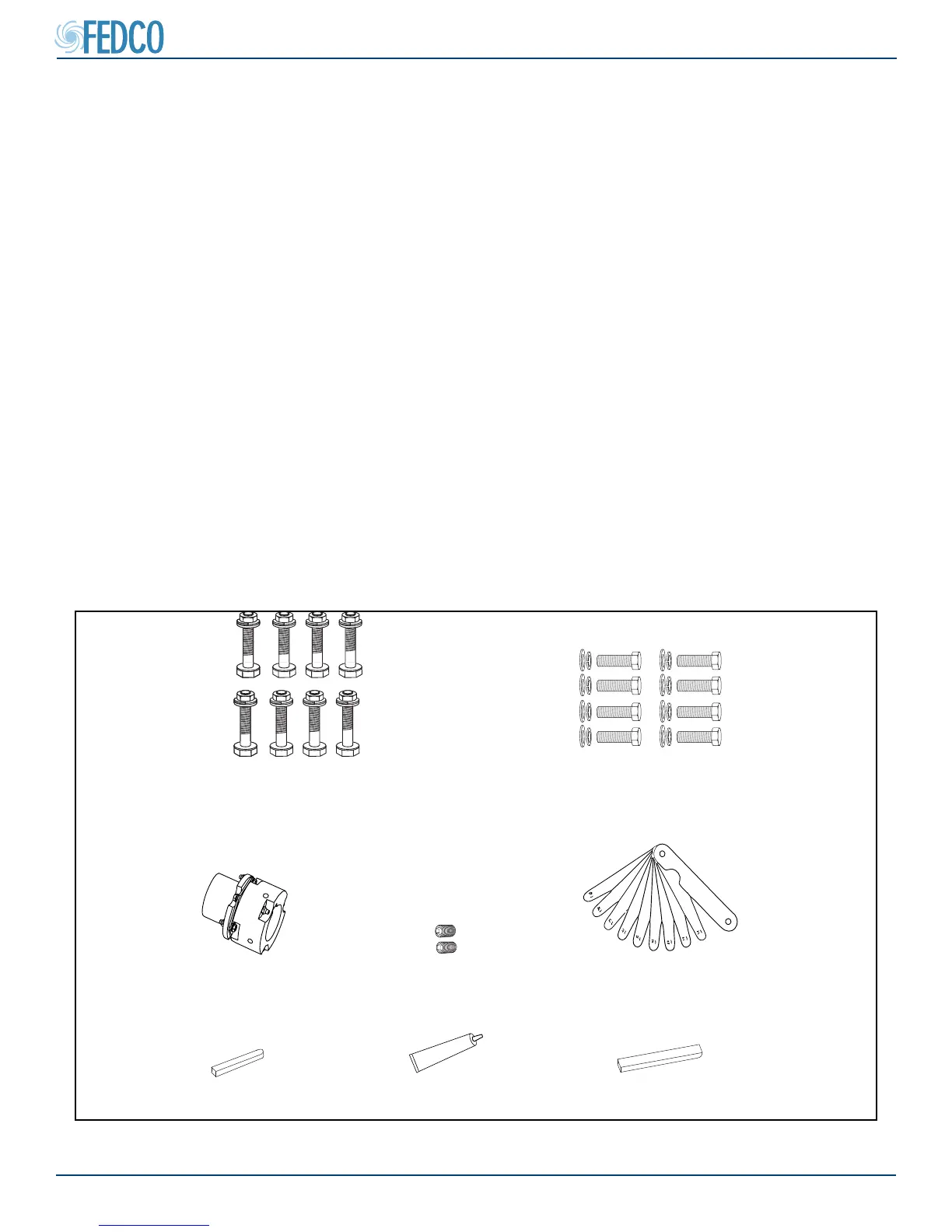

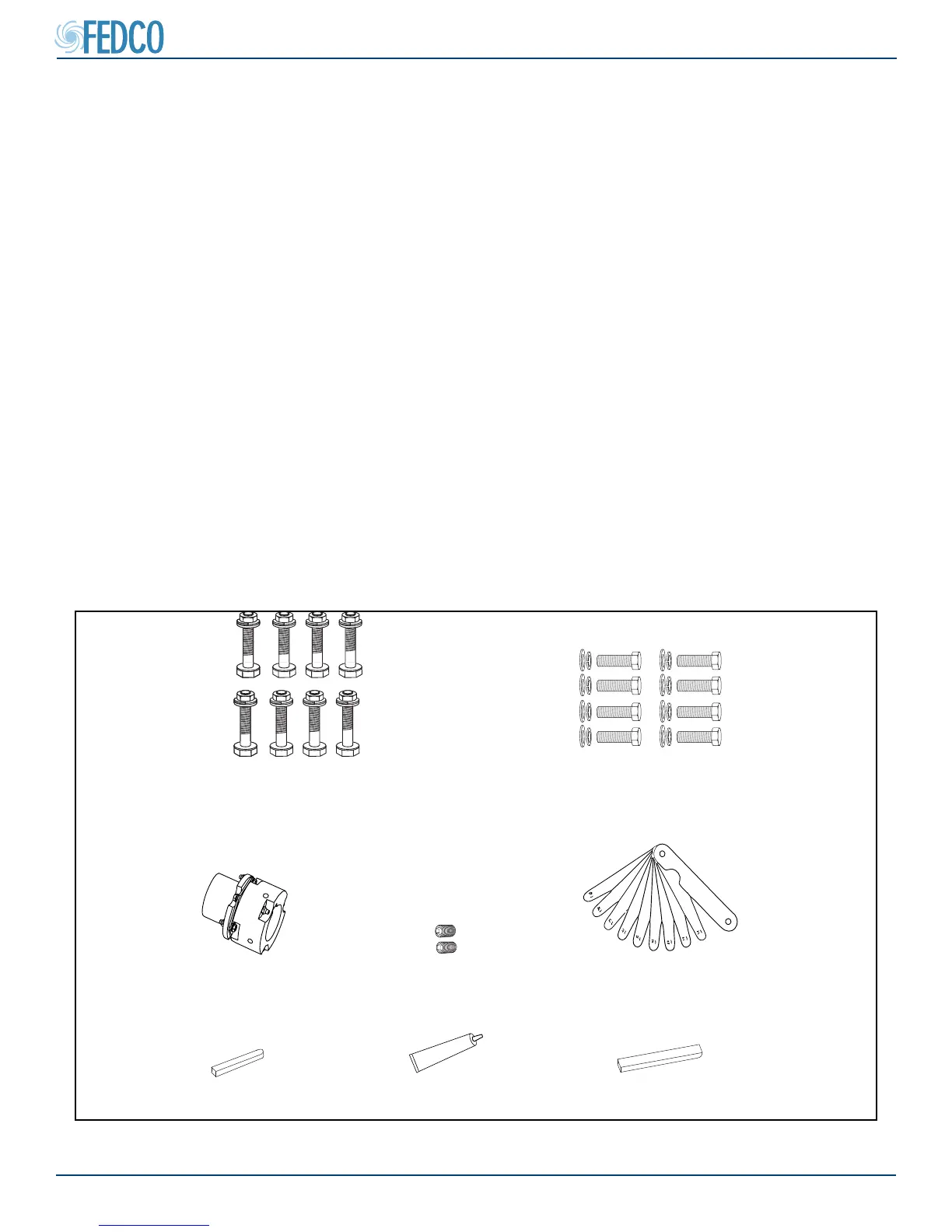

• In most instances, the unit and motor are shipped pre-assembled. All necessary installation

accessories will be included with the pump.

Feeler Gauges

(Horizontal orientation only)

Anit-seize compound

ANTI-SEIZE

Motor adapter bolts with washers

(note that quantities may vary, depending on pump size)

Coupling set screws

Pump shaft key

Coupling

Motor mounting bolts with washers and nuts

(if motor and baseplate is provided by

FEDCO)

(note that quantities may vary, depending on pump size)

Motor shaft key (if motor is

provided by FEDCO)

Figure 2 - Installation Accessories

Loading...

Loading...