601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-2A-210

INSTALLATION & OPERATION INSTRUCTIONS

TYPE PSE PAD-MOUNTED SWITCHGEAR

NOVEMBER 2017, REV 4.2

PAGE 5

Customer Cable Connections

1. Make up the primary cable connections per user’s standard URD

operating procedures, cable manufacturer instructions, and elbow

terminator manufacturer instructions.

Installation

Each unit is shipped with this instruction bulletin, which is located

inside the switch compartment door. These instructions should be

reviewed prior to placing unit on pad.

Placement of Unit

Remove unit from shipping pallet per handling procedures on Page

2 (see Figure 3). When unit has been correctly oriented and placed

on pad (see Figure 7), verify that unit is level and shim if necessary

between unit base and pad. Secure unit to pad using four (4) tie-down

clips as furnished (see Figures 8 and 9). Check compartment door

operation for any binding due to enclosure distortion and re-shim

if necessary. A recessed grouting should then be applied between

unit base and pad to prevent entry of foreign objects and moisture.

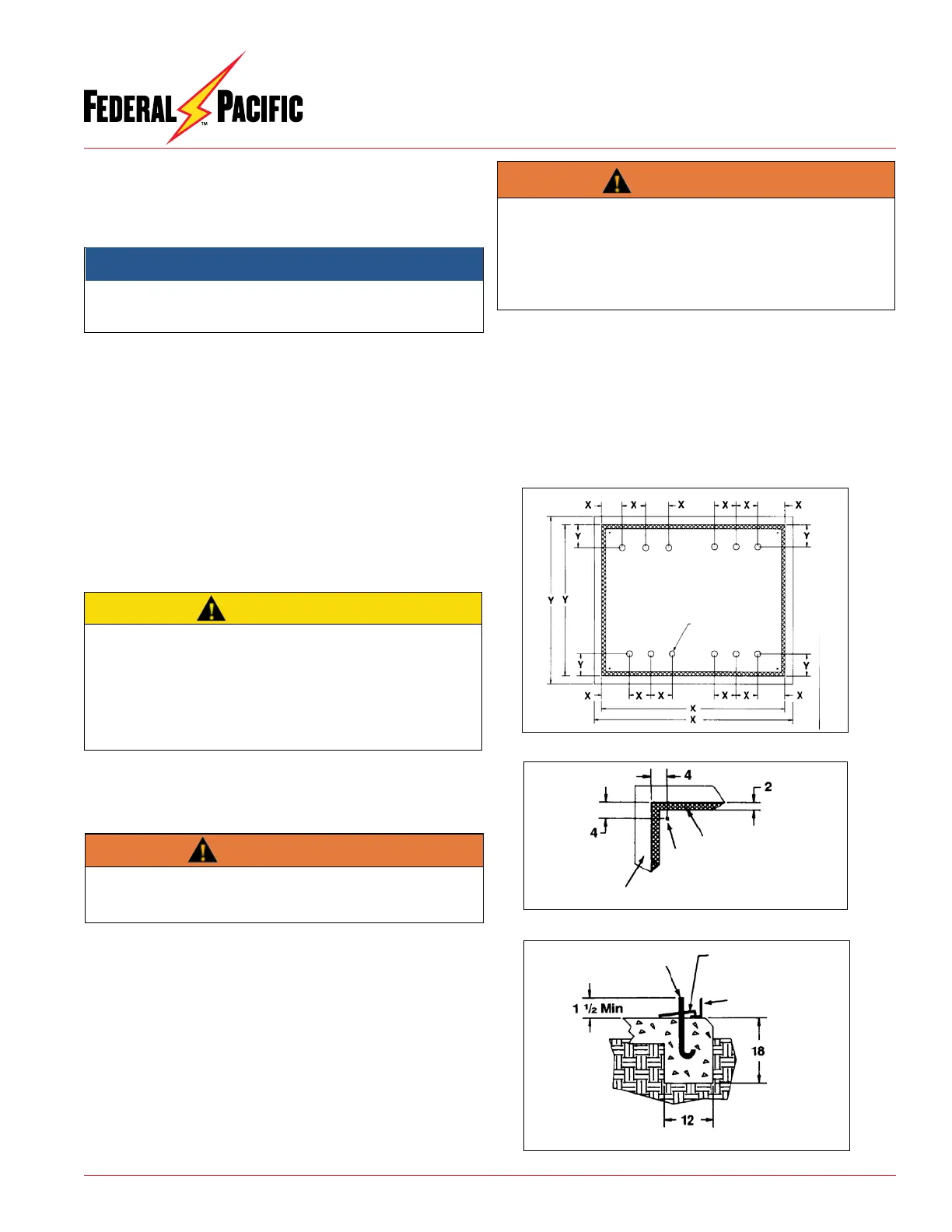

Figure 7. Typical Pad Layout

PSE-X

Recommended Pad Layout

Approximate Cable

Locations

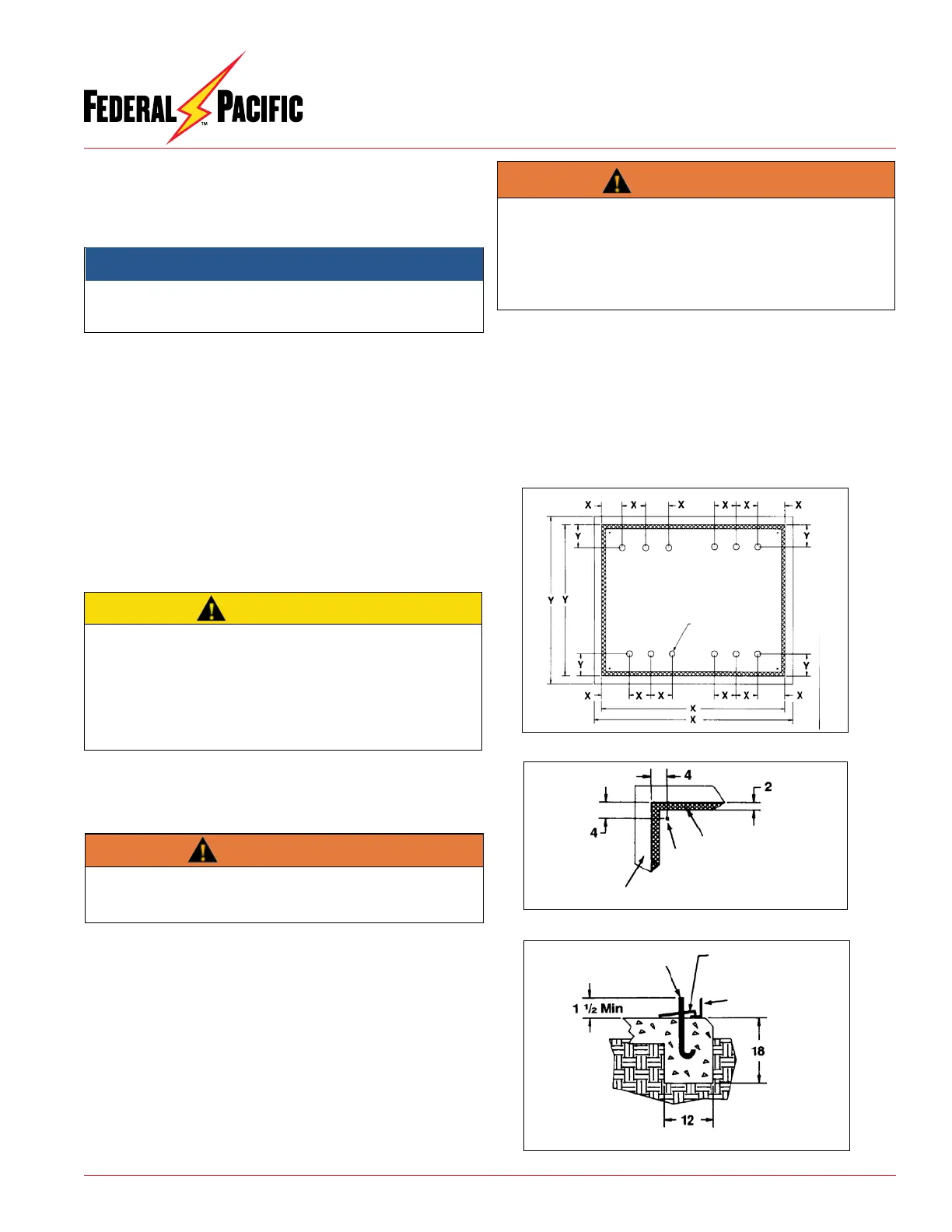

Figure 8. Typical Anchor Bolt Location

Base of Cabinet

Customers Pad

Corner Detail

Anchor Bolt

Figure 9. Bolting Units to Pad

Cabinet

5/8-11 Anchor

Bolts (by others)

4 Tie Down

Plates Provided w/Unit

Recommended Pad Section

Before energizing the switchgear, remove all yellow and red

shipping caps on bushings and bushing wells, and replace

them with a suitable system of insulated separable connectors

(elbows), insulating protective covers, or plugs, as appropriate.

Failure to replace the shipping caps may result in flashover,

equipment damage, serious personal injury, or death.

WARNING

2. Connect the concentric neutral wires to the enclosure ground

pads inside enclosure to facilitate ground system conforming to

user’s grounding procedures.

NOTICE

Installer shall provide appropriate clear working space, as re-

quired by applicable codes and/or work practices, to allow instal-

lation, operation, inspection, and maintenance of the switchgear.

CAUTION

When terminating cables in dead-front switchgear, ensure that

each cable termination connector lays flat against the correspond-

ing flat copper contact surface of the associated bushing, prior

to making up the elbow, so that no additional strain is put on the

bushing. The connecting hardware and components of dead-break

T-body elbows are not to be used to pull the cable terminations

into alignment with the bushings.

3. Install fault indicators, if applicable.

4. Fuse Compartment Cable Positioning

a) Cable connections to the loadbreak fuse mounting terminals must

be fed through the cable guides, which are located under the

parking stands. This is required to permit the proper operation

of the pivoting fuse mountings.

b) Each cable guide may be rotated or temporarily removed to

facilitate cable installation, so long as it is returned to its original

orientation, under its corresponding parking stand, after the

cables are installed.

Switch Description

The Auto-jet

®

II switch provides a unique method of load interruption,

producing a laminated jet of air which extinguishes the arc.

Auto-jet

®

II switches have a heavy gauge steel, all welded base

frame that assures proper alignment and eliminates any problem

with switch-to-enclosure alignment. A quick-make, quick-break

stored energy mechanism with heavy duty, long life die springs

provides high speed opening and closing independent of the op-

erating handle speed.

WARNING

The maximum momentary rating of the switchgear must be

considered when selecting cable size for connecting switch-

gear to system ground. Refer to unit rating plate.

Loading...

Loading...