Lubrication

This unit is equipped with twenty four (24) different grease

fittings that must be lubricated on this unit. They must be

lubricated at the intervals as specified in the

Maintenance Chart

.

Qty of

Fittings

Grease fitting Location

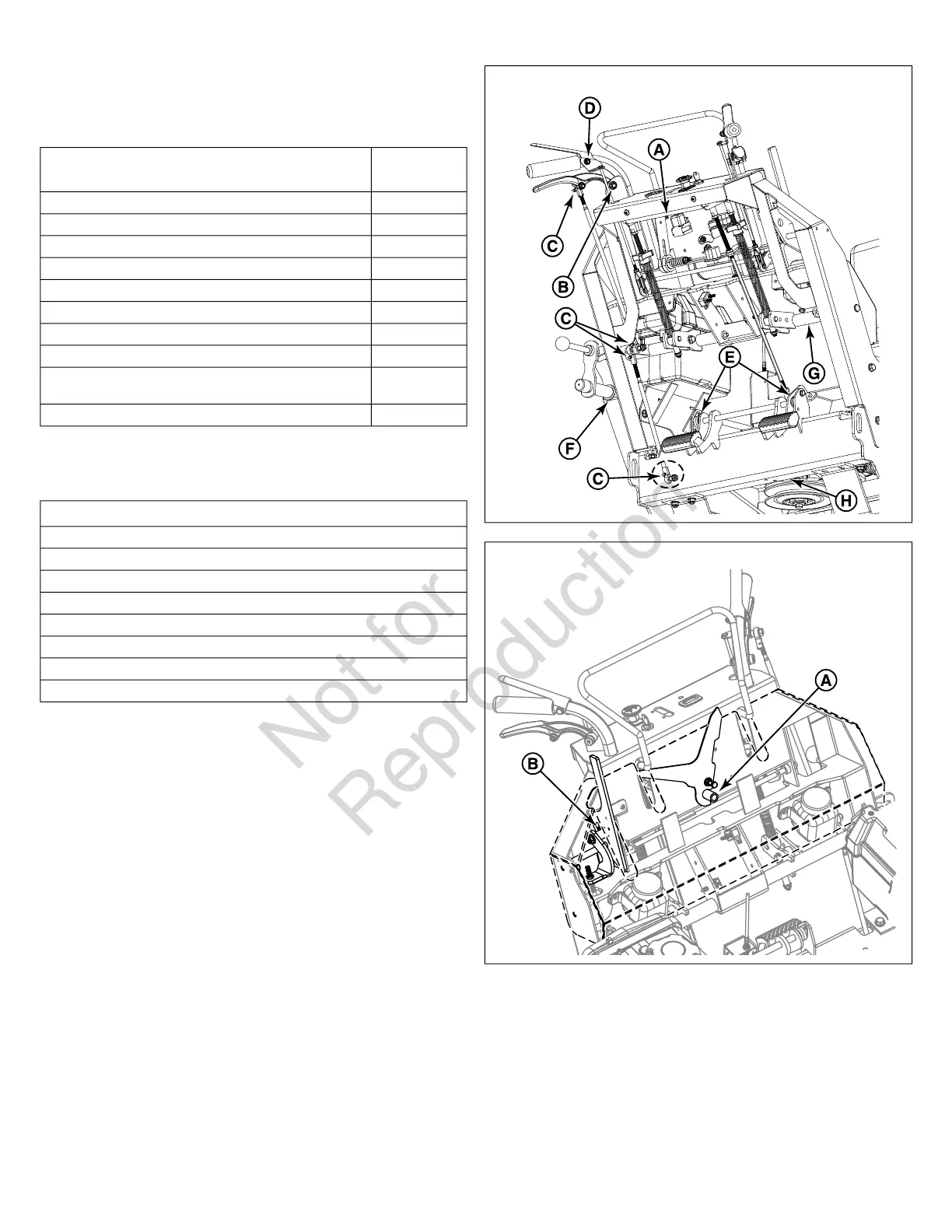

1Forward Speed Control Lever Rod (A, Figure 17)

2Drive Lever Pivots (B)

8Grease-able Ball Joints (C)

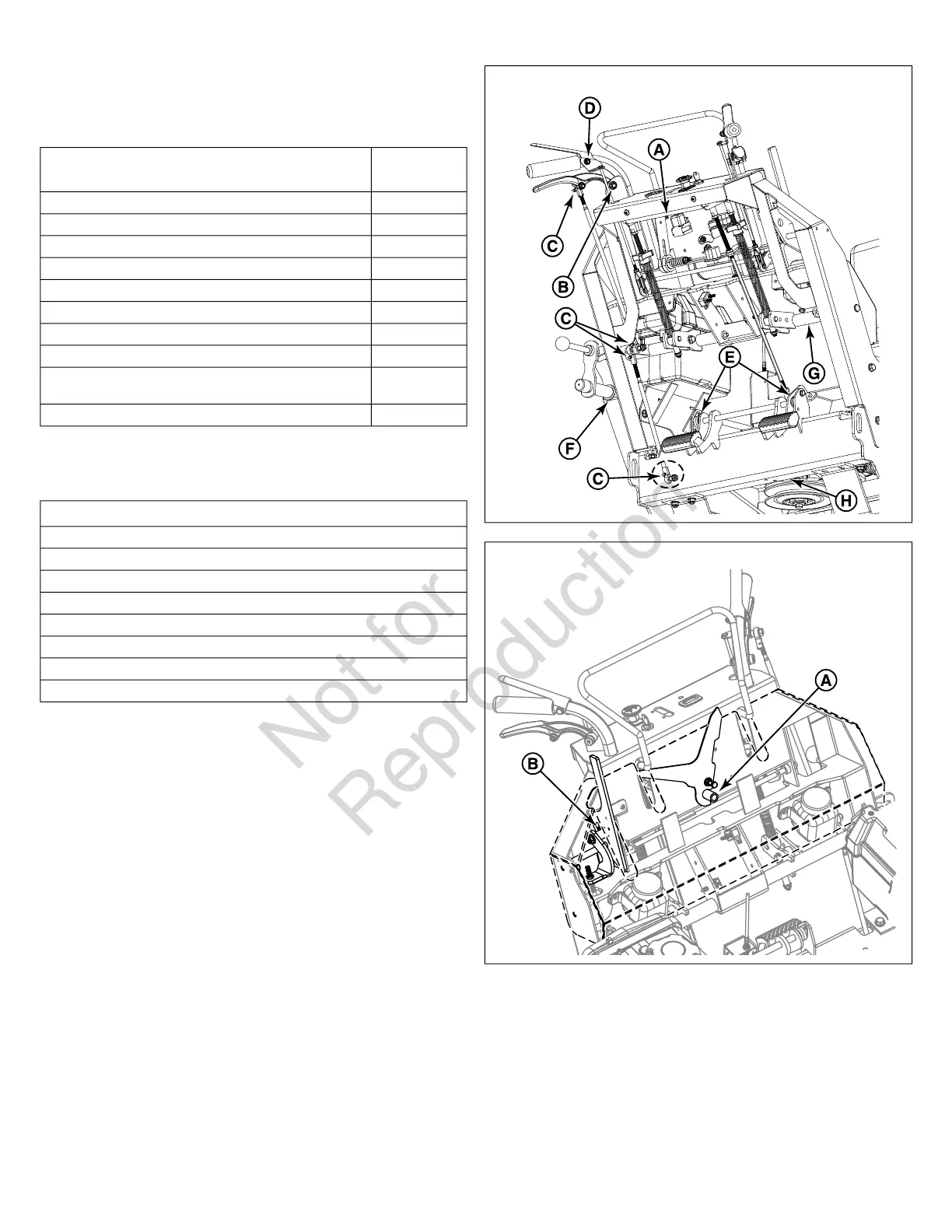

1Forward Speed Indicator Pivot (A, Figure 18)

1Parking Brake Pivot (B)

2Frame Rails (A, Figure 19)

4Deck Adjusters (B)

3Mower Deck Spindles (A, Figure 20)

2Front Caster Wheel Axles (See

Lubricating the Front Casters

)

(A, Figure 21)

N/AFront Casters (See

Lubricating the Front Casters

)

Not all greases are compatible. Red grease (p/n 5022285) is

recommended, automotive-type, high-temperature, lithium

grease may be used when this is not available.

Oil Application Locations

Operator presence flap pivots (D, Figure 17)

Neutral return pedal pivots (E)

Deck Lift Crank Pivots (F)

Control Rod Pivots (G)

Lower Parking Brake Rod Pivots (H)

Deck Lift Linkage Rods (C, Figure 19)

Deck Lift Trunnions (D)

Discharge Chute Rod Hinge (B, Figure 20)

Generally, all moving metal parts should be oiled where contact

is made with other parts. Keep oil and grease off belt and

pulleys. Remember to wipe fittings and surfaces clean both

before and after lubrication.

17

18

22 ferrisindustries.com

Loading...

Loading...