– Pay attention to cleanliness while repairing the quarter-turn actuator. Do not allow dirt particles to get into the quar-

ter-turn actuator.

– A shutdown must be performed before any repair work is carried out.

– Before repairing the quarter-turn actuator, any attachments on it must be dismantled.

– The control block must be completely depressurised and de-energised, and reliably secured against unauthorised

restarting before starting any repair work is started.

– Accidental switching on or concealed pressure can trigger unexpected movements during dismantling of the quar-

ter-turn actuator. Therefore, completely vent the quarter-turn actuator before each repair.

– Use original spare parts only to repair the quarter-turn actuator.

– Wear the necessary personal protective equipment.

– In the event of damage to the quarter-turn actuator caused by

– unauthorised manipulation,

– non-intended use (misuse),

– use of non-original spare parts

all warranty and liability claims against the manufacturer expire.

– The technical documentation required for installation and start-up (functional test) of the quarter-turn actuator must

be available.

2.2 General information

– Standard tools are needed to repair the quarter-turn actuator, which must be available in a service workshop

( Chapter 1.4 on page 6).

– Components and equipment replaced during repair must be disposed of in accordance with the relevant local

environmental protection regulations.

– Where possible the repair should be carried out on a stable and at work surface with space for small parts.

– The gures of the repair steps show size DFPD-300-…-D / S-…-60 (12 installed springs) by way of example. Individual

minor differences between the quarter-turn actuator in hand and the illustrated example are possible.

– Depending on the temperature range (standard / T4 / T6), Festo recommends the following lubricants:

– SYNTHY POLYMER 402/2 (standard variant)

– HEVOLIT PE 280-1 FG (high-temperature variant T4)

– RENOLIT SI 300 M (low-temperature variant T6)

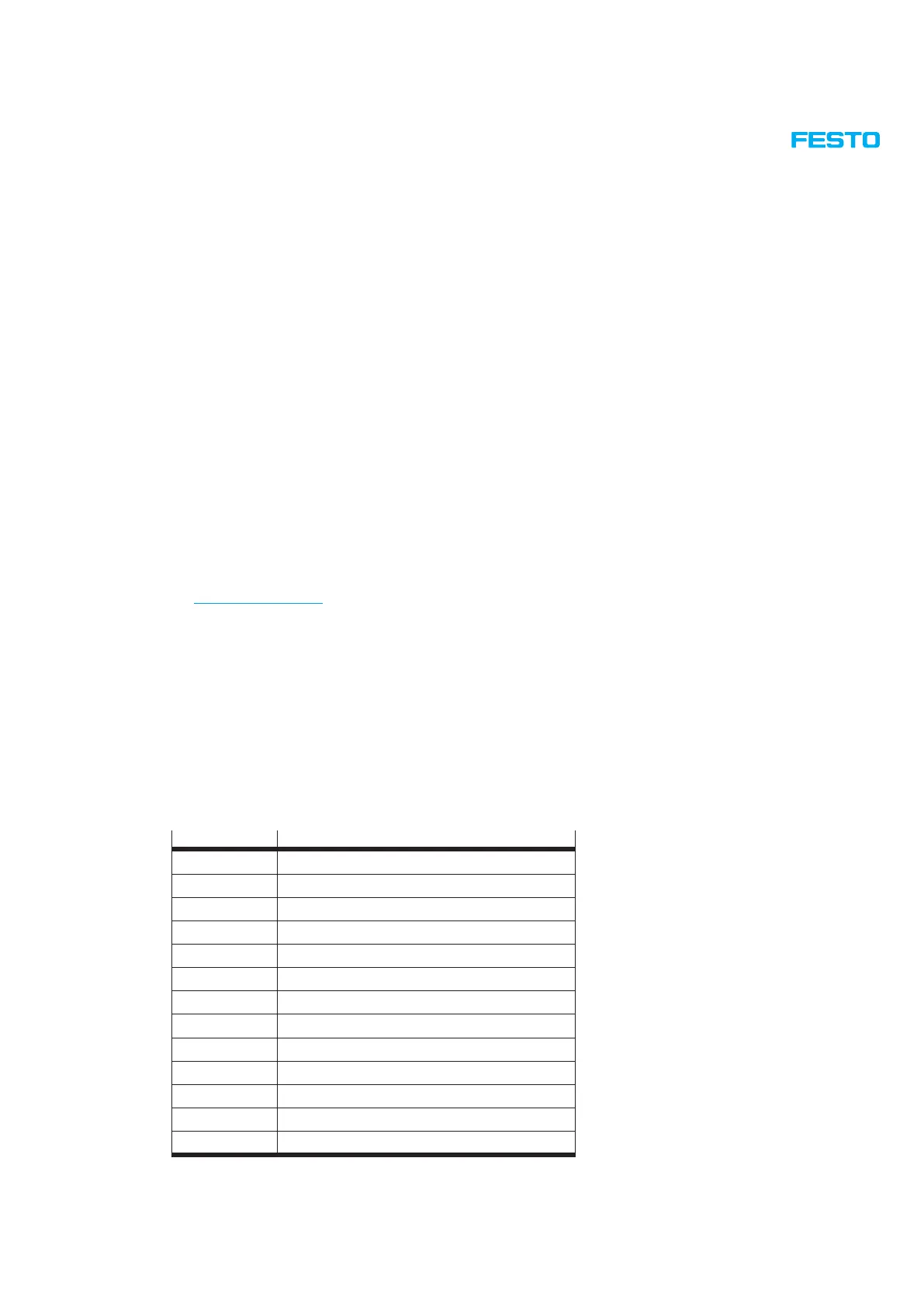

– Individual components must be greased when installing the quarter-turn activator. The following table shows the

recommended quantity of grease during the entire installation.

Size Recommended quantity of grease for installation

DFPD-10 2 g

DFPD-20 3 g

DFPD-40 5 g

DFPD-80 7 g

DFPD-120 11 g

DFPD-160 15 g

DFPD-240 20 g

DFPD-300 30 g

DFPD-480 45 g

DFPD-700 55 g

DFPD-900 65 g

DFPD-1200 85 g

DFPD-2300 110 g

7 / 74DFPDb_en

Loading...

Loading...