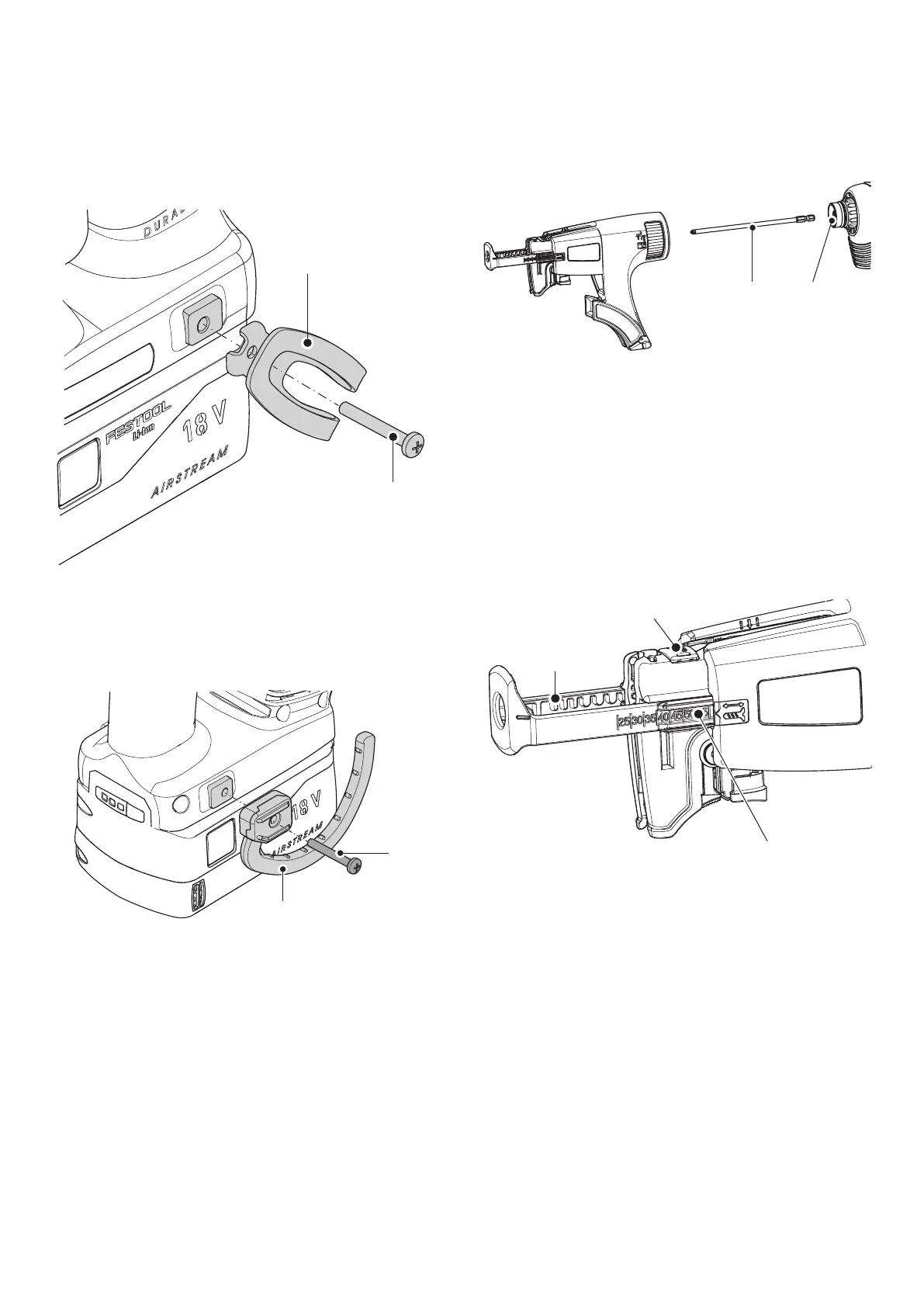

10.3 Frame hook and belt clip

The belt clip [6-1] can be used to attach the tool

to working clothes temporarily – it can be af

fixed to the left or right-hand side of the tool

using a screw [6-2], making it suitable for

right-handed and left-handed operators – see

figure [6].

The tool also has a hook [7-1], by which the tool

can be hung, as required. It can be affixed to the

left or right-hand side of the housing using the

screw [7-2] – see figure [7].

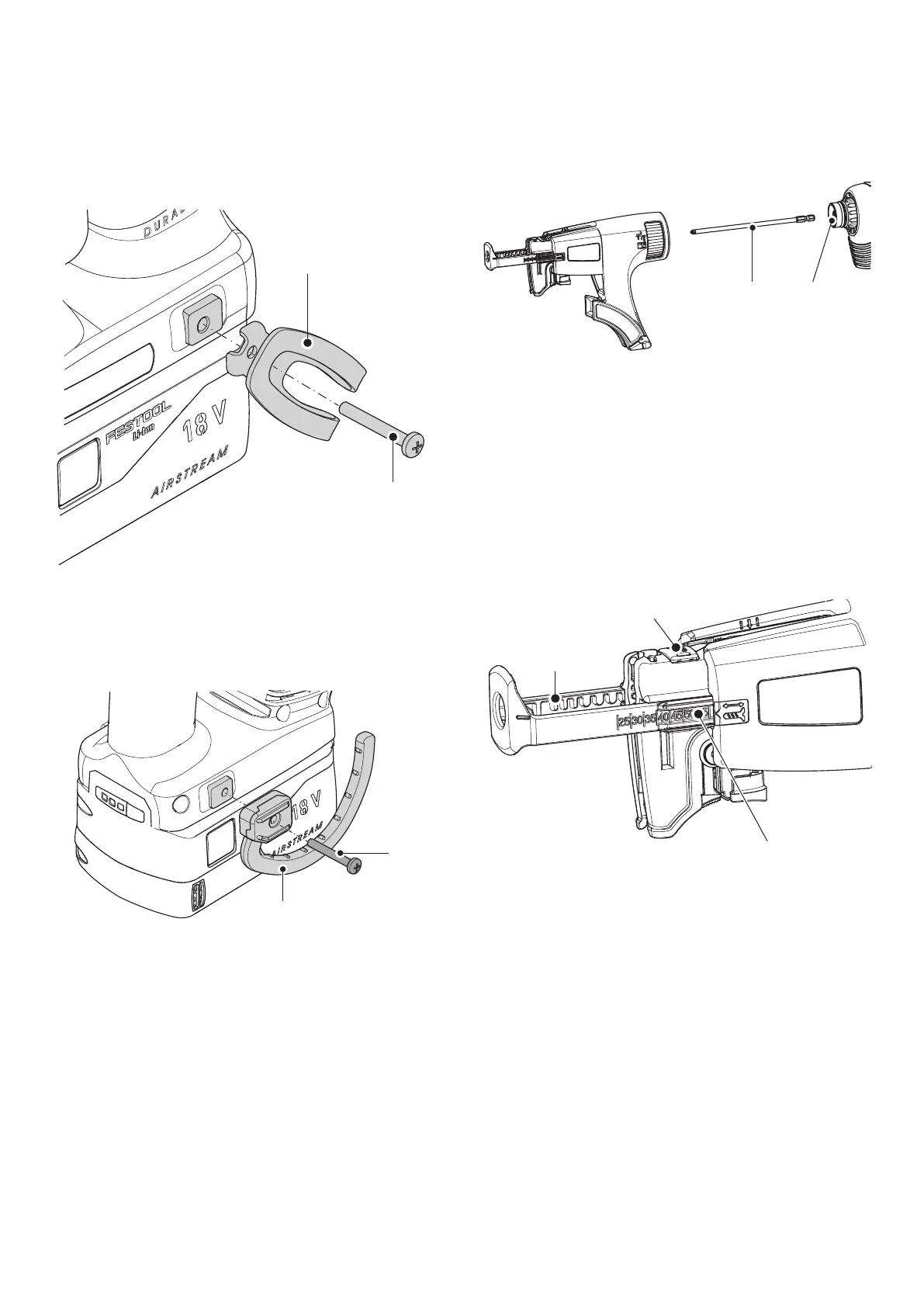

10.4 Magazine attachment

The magazine attachment enables the operator

to work continuously without unnecessary

pauses.

Fitting the magazine attachment

► Remove the depth stop [5-1] on the bit

holder [3-2] using the bit, as described in

section

9 .

► Move the selector switch [1-4] to the MAN

position.

► Push the long bit [8-1] into the tool hold

er [8-2] until it clicks into place.

► Then affix the magazine attachment to the

transmission housing. The magazine at

tachment must audibly click into place.

► The magazine attachment can be positioned

at 30° increments.

Removing the magazine attachment

► Take the magazine attachment out of the

transmission housing by pulling firmly.

Adjusting the screw length

► Pressing on the button [9-1] slides the

depth stop [9-2] in or out, so that it can be

adjusted to the required screw length.

The screw length setting is visible on the sides

of the depth stop [9-3].

Inserting collated screws

► Firstly, draw the belt of collated

screws [10-3] through the lower magazine

guide and then thread them into the car

riage guide until a screw clicks into the

working position.

Make sure that the screws are correctly

positioned and secure by pulling gently on

the belt of collated screws.

Check that the first screw is lined up in the

screwing axis – see figure [10].

► Use the adjusting wheel [10-1] to set the

required insertion depth.

► Clockwise rotation will countersink the

screws further in, while anticlockwise rota

tion will countersink the screws further out.

English

13

Loading...

Loading...