8 Settings

WARNING

Risk of injury, electric shock

► Always pull the mains plug out of the sock

et before performing any type of work on

the machine!

8.1 Electronics

The machine features full-wave phase control

electronics with the following features:

Smooth start-up

The electronically controlled smooth start-up

function ensures that the power tool starts up

smoothly.

Constant speed

The motor speed is electronically kept con

stant. This ensures a uniform cutting speed

even when under load.

Speed control

You can continuously adjust the speed within

the speed range using the adjusting

wheel [1-10] (see Technical data). This enables

you to optimise the cutting speed to suit specific

surfaces (see table).

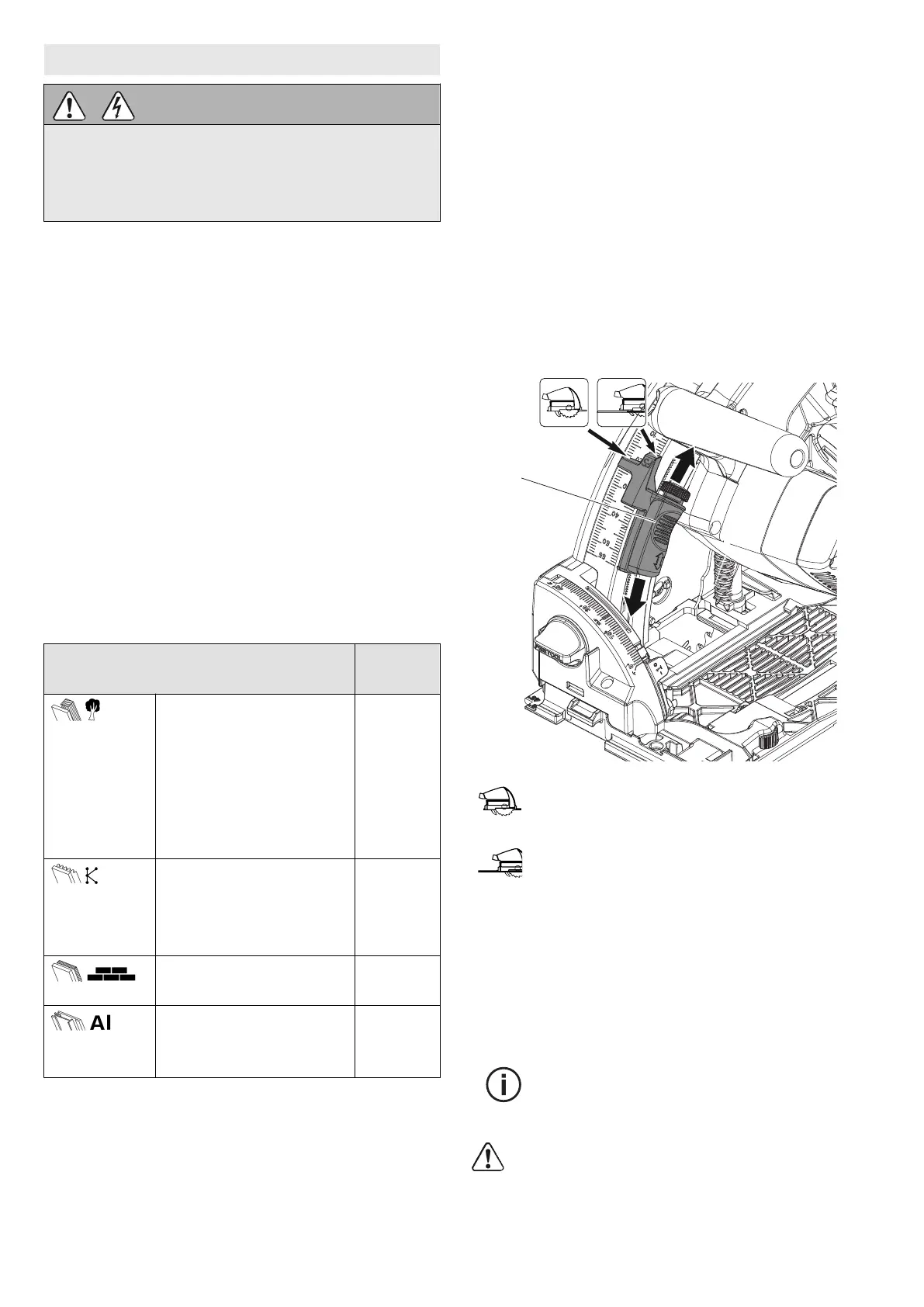

Material Speed

range

Solid wood (hard,

soft)

Chipboard and hard

board

Laminated wood,

blockboard, veneered

and laminated panels

6

3-6

6

Plastics, fibre-rein

forced plastics (FRP),

paper and mesh

Acrylic glass

3-5

4-5

Gypsum and cement-

bonded fibreboard

1-3

Aluminium panels

and profiles up to

15 mm

4-6

Temperature cut-out

When exceeding a certain engine temperature

level, the machine power supply and speed are

capped. The power tool continues operating at

reduced power to allow the ventilator to cool

the motor rapidly. The power tool resumes to

full performance automatically once the motor

has cooled sufficiently.

Current limiting

Current limiting prevents excessive current

consumption under extreme overload, which

can lead to a decrease in the motor speed. The

motor immediately restarts after the load is re

moved.

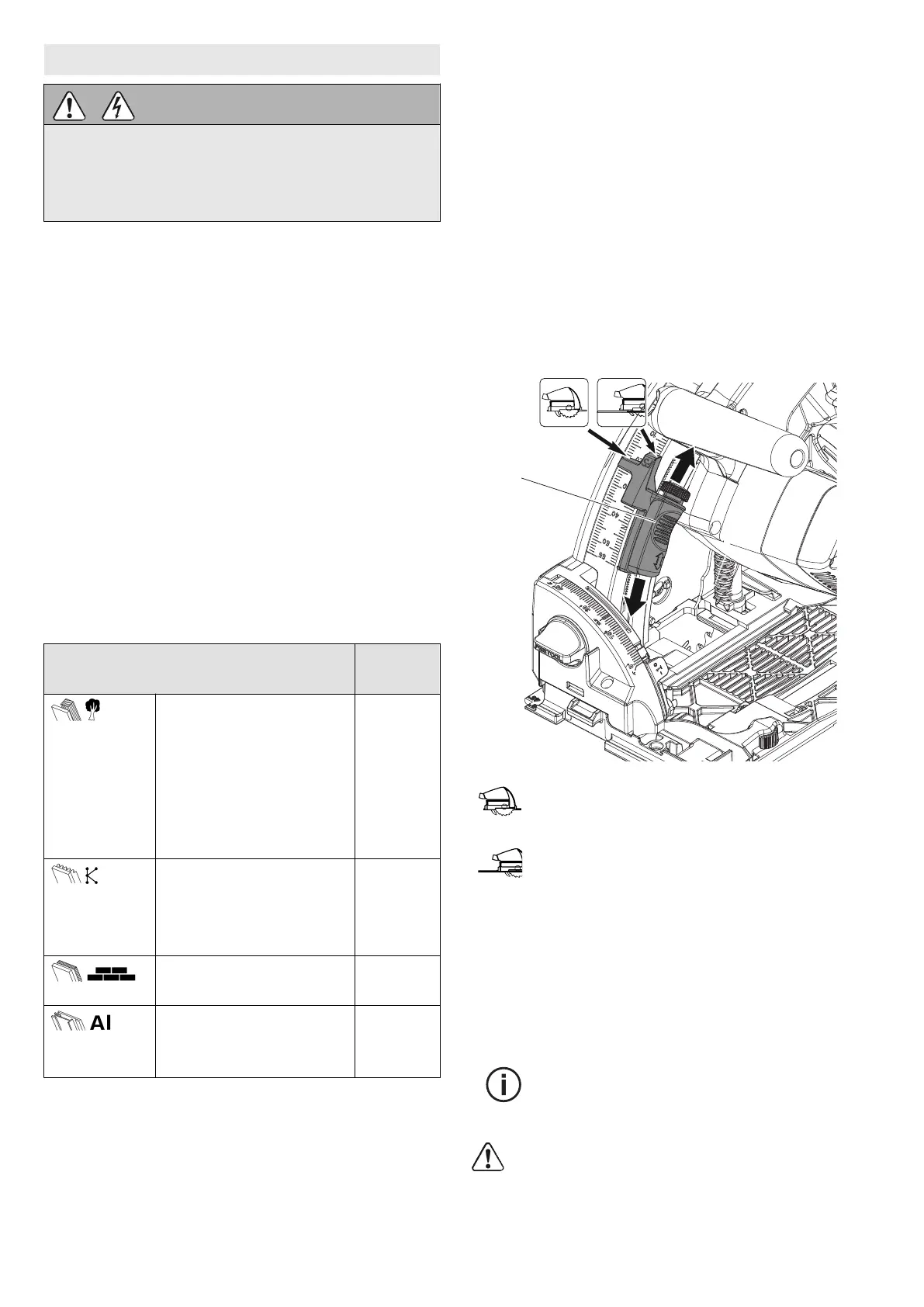

8.2 Adjusting the cutting depth

The cutting depth can be adjusted to between 0

and 2-1/8" (55 mm) on the cutting depth

stop [3-1]:

The sawing unit can now be pressed down to

the set cutting depth.

Cutting depth without guide rails

max. 2-1/8" (55 mm)

Cutting depth with guide rail FS

max. 1-15/16" (51 mm)

8.3 Adjusting the cutting angle

between 0° and 45°:

► Unscrew the rotary knobs [4-1].

► Swivel the sawing unit to the desired cutting

angle [4-2].

► Tighten the rotary knobs [4-1].

Both positions (0° and 45°) are set at

the factory and can be readjusted by

the customer service team.

When making angled cuts, slide the view

ing window/splinter guard to the highest

position.

English

12

Loading...

Loading...