CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

The Field One Nucleus engine was designed to give your Force

maximum reliability with minimal maintenance. The Nucleus engine

uses U-Cup directional seals along side traditional O-rings.

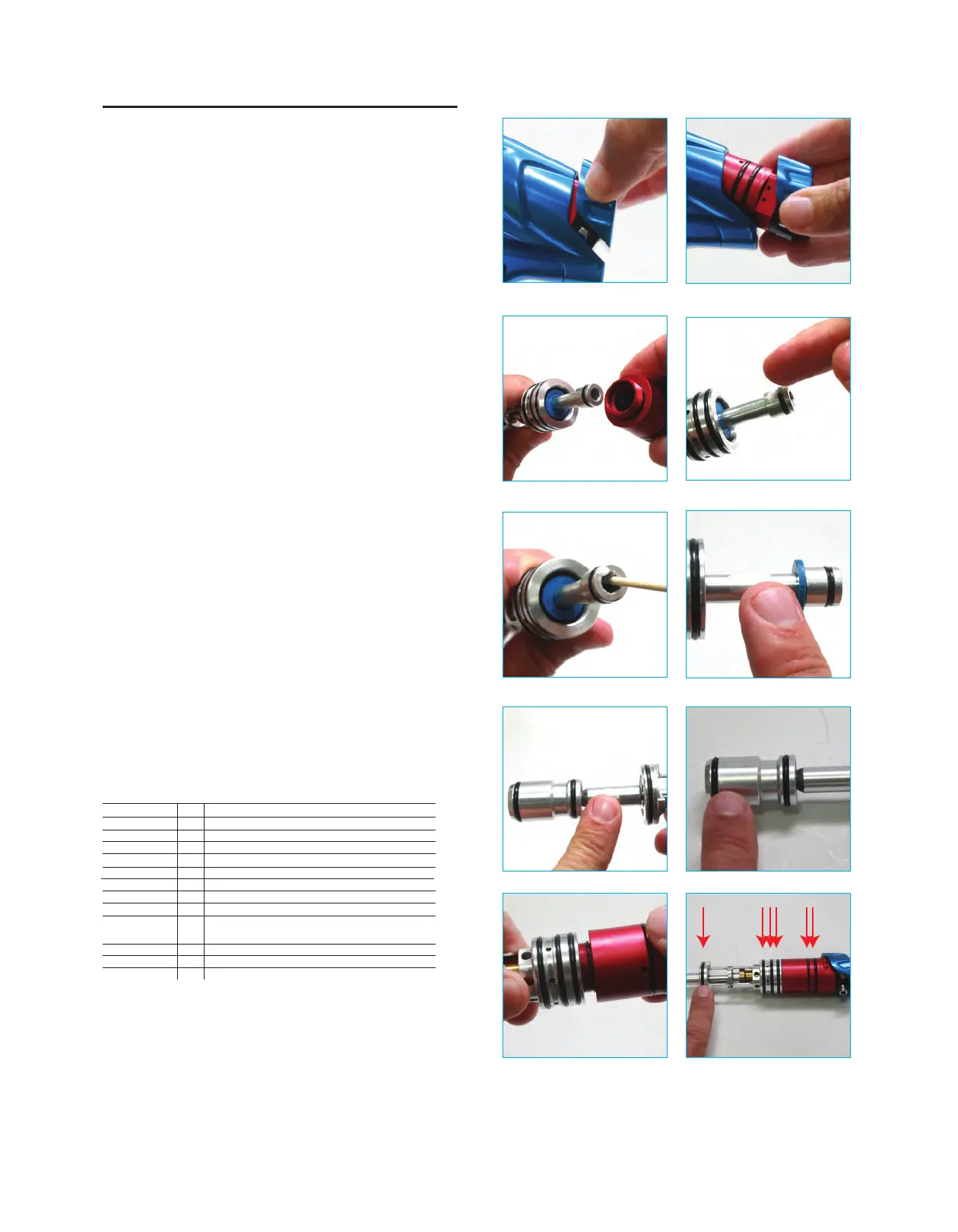

1) To remove the engine de-gas your marker and make sure there is

no pressure retained inside the marker. Pull up on the back cap

until it lifts away from the main body (fig 11A). If the cap does not

lift the gun may still be presurized. Empty the chamber by dry

fireing a shot in a safe location.

2) Pull the engine out towards the rear of the marker (fig 11B). Once

the engine is separated from the body you can separate the two

engine halves.

3) To seperate the engine halves unscrew the volume chamber from

the ram housing these parts should be tightly screwed together so

you may want to uses a towel to hold the volume chamber as you

twist. (fig 11C)

4) Apply grease to the.

• External Ram Shaft O-ring (U-cup 011) (fig 11D)

• Internal Ram Shaft O-ring (U-cup 009) (fig 11E). (You can

use a cotton swab r small allen wrench.)

• The ram shaft in front of the blue extension bumper. (fig 11F)

• The Bolt Stem.(fig 11G)

• A very light layer of grease on the bolt and bolt o-rings. (fig

11H) (if too much grease is applied here it may affect eye

performance).

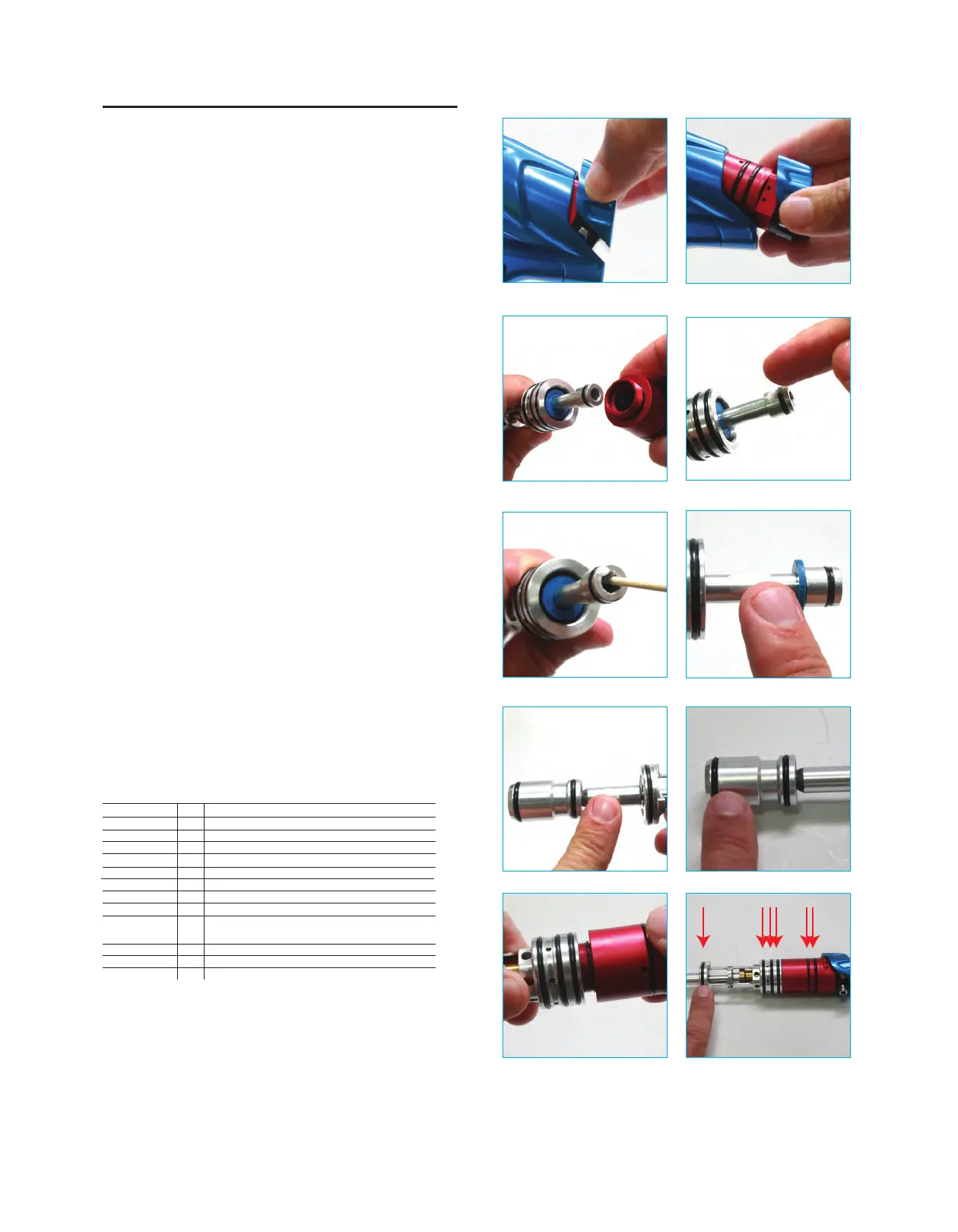

5) When rejoining the two engine halves, be sure to tighen them

togather to insure a tight fit. (fig 11I)

6) Add a small amout of grease to the static o-rings around the

outside of the engine to insure a smooth re-entry. (fig 11J)

7) To reinstall your engine make sure the back cap is in the up

posintin and gently slide the engine back into the marker.

8) Once it is completely inserted push down on the back cap untill it

snaps into place.

You do not need to change any of the seals unless there is an

obvious leak or fault in performance. When troubleshooting always

make sure your air tank has adaquire pressure and is screwed into

the ASA completely and the cam drive knob is fully engaged. Make

sure the marker has fresh batteries. Please consult the complete

manual at fieldonepaintball.com for trobleshooting guide ad FAQ.

Engine O-ring Index

(fig 11A) (fig 11B)

(fig 11C) (fig 11D)

(fig 11E) (fig 11F)

(fig 11G) (fig 11H)

(fig 11I) (fig 11J)

O ring 1x3

O ring 1x2

O ring 021

O ring 021

U Cup 009

O ring 020

U Cup 110

O ring 017

U Cup 011

U Cup 011

O ring 011

O ring 015

O ring 1x15

2

1

2

3

1

1

1

2

1

2

1

2

1

Back Block Detent Plunger

Reduction Shaft to Ram Housing

Outside Ram Housing

Outside Volume Chamber Rear

Inside Ram (opening faces front)

Outside Volume Chamber Front

Front of Volume Chamber (opening faces back)

Inside Volume Chamber Outside Brass Shut Off

Back of Ram (opening faces front)

Inside Brass Shut Off

(openings face away from eachother)

Inside Front Brass Shut Off

Outside Bolt

In between Engine Halfs

FORCE ENGINE MAINTENANCE

Loading...

Loading...