CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

RHINO REGULATOR (HPR) The Rhino regulator is an ultra compact

high pressure regulator that offers high flow and was designed to

require minimal maintenance. An indication that the regulator needs

maintenance is a high spike in velocity or a leak in the regulator area.

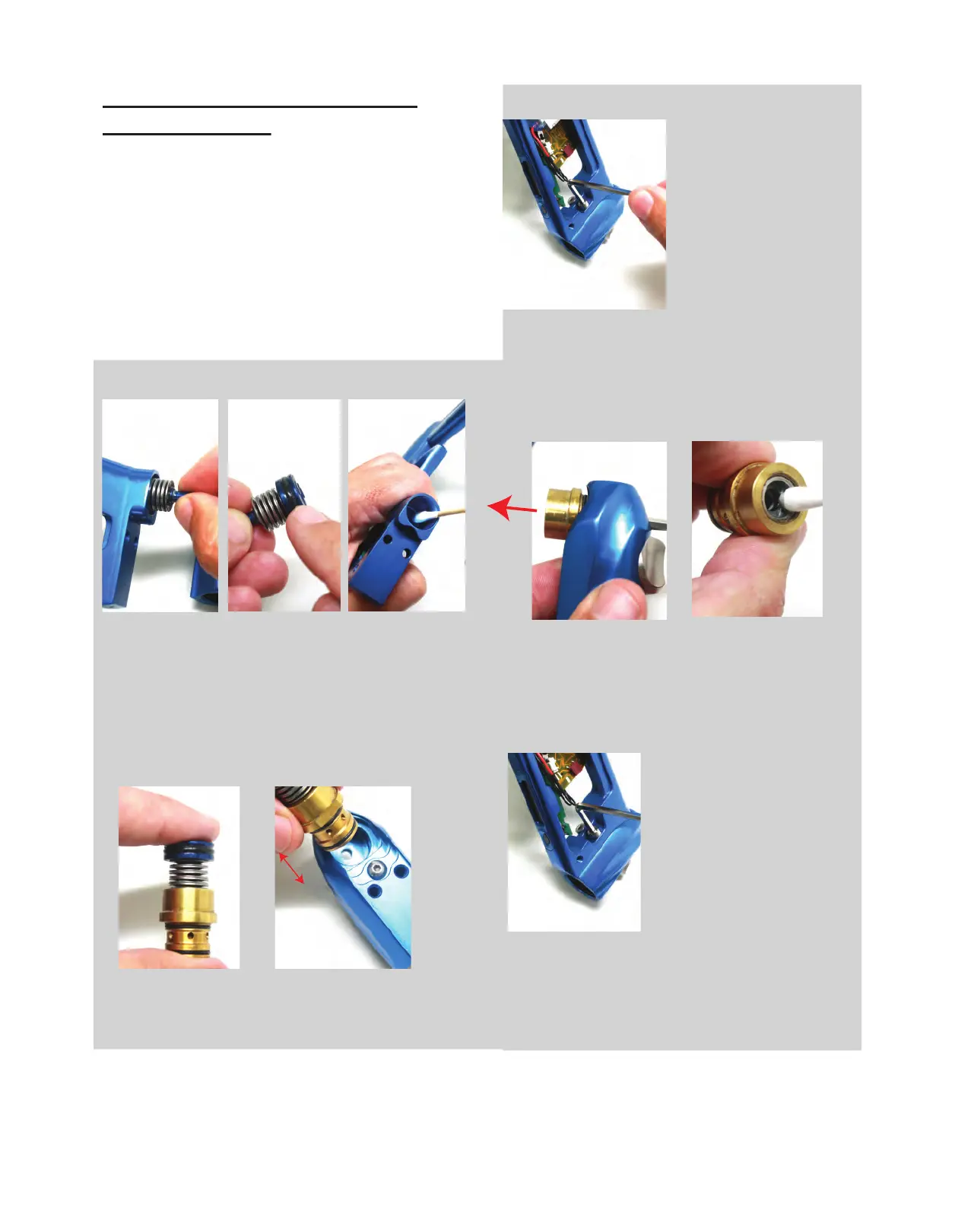

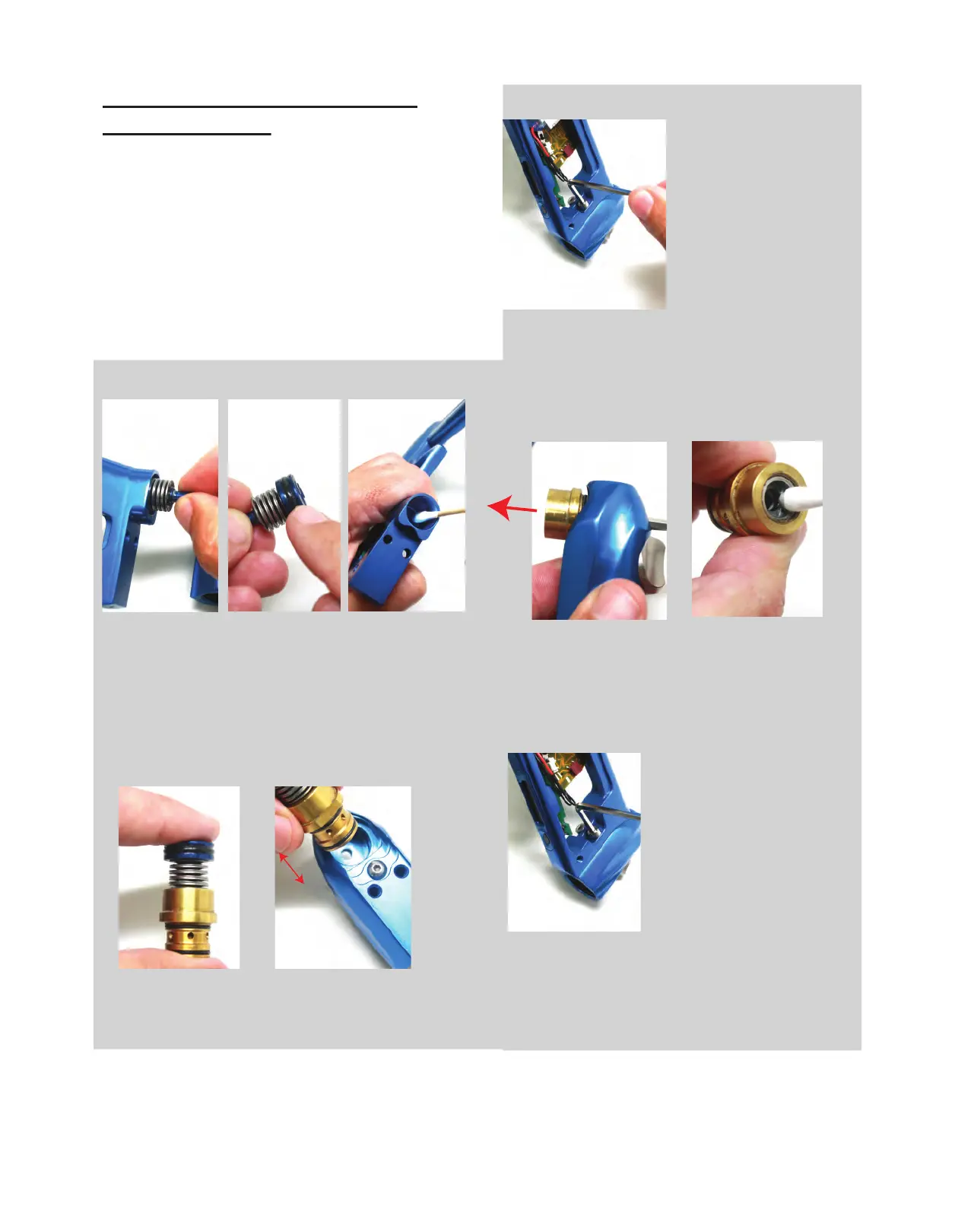

To access the Rhino Regulator open the grip panels on both sides

and remove the ASA and Regulator from the grip frame by unscrew-

ing the ASA mounting screws with a 1/8 allen wrench (fig 1). Remove

the reg piston and clean and grease the piston o-ring (fig 2). Clean

and grease the piston housing inside the grip frame. Clean and

grease the (008) o-ring underneath the c-clip inside of the brass

regulator adjuster housing (fig 4). Use a cotton swab to clean the reg

seat at the bottom of the brass regulator adjuster housing (fig 4).

When re-assembling the Rhino Regulator make sure to clean and

apply grease to all o-rings..

FORCE RHINO REGULATOR

MAINTENANCE

4. Clean and grease the

o-ring inside the adjuster

housing using a swab. Clean

the reg seat at the bottom of

the adjuster housing assembly.

6. Press reg assembly and ASA

back into the bottom of the

grip frame and firmly tighten the

mounting screws.

3. Remove brass adjuster

housing by pressing it out

of the ASA using a 1/8

allen wrench.

5. Clean inside of the ASA reg housing and apply light grease to

static o-rings. Reassemble Rhino Regulator and reinsert into the ASA

reg housing. The flat edge of the brass piston guide aligns with the

rear of the ASA housing.

1. Remove ASA screws

using 1/8 allen wrench

2. Remove reg piston. Clean

and grease o-ring, stem and housing.

Loading...

Loading...