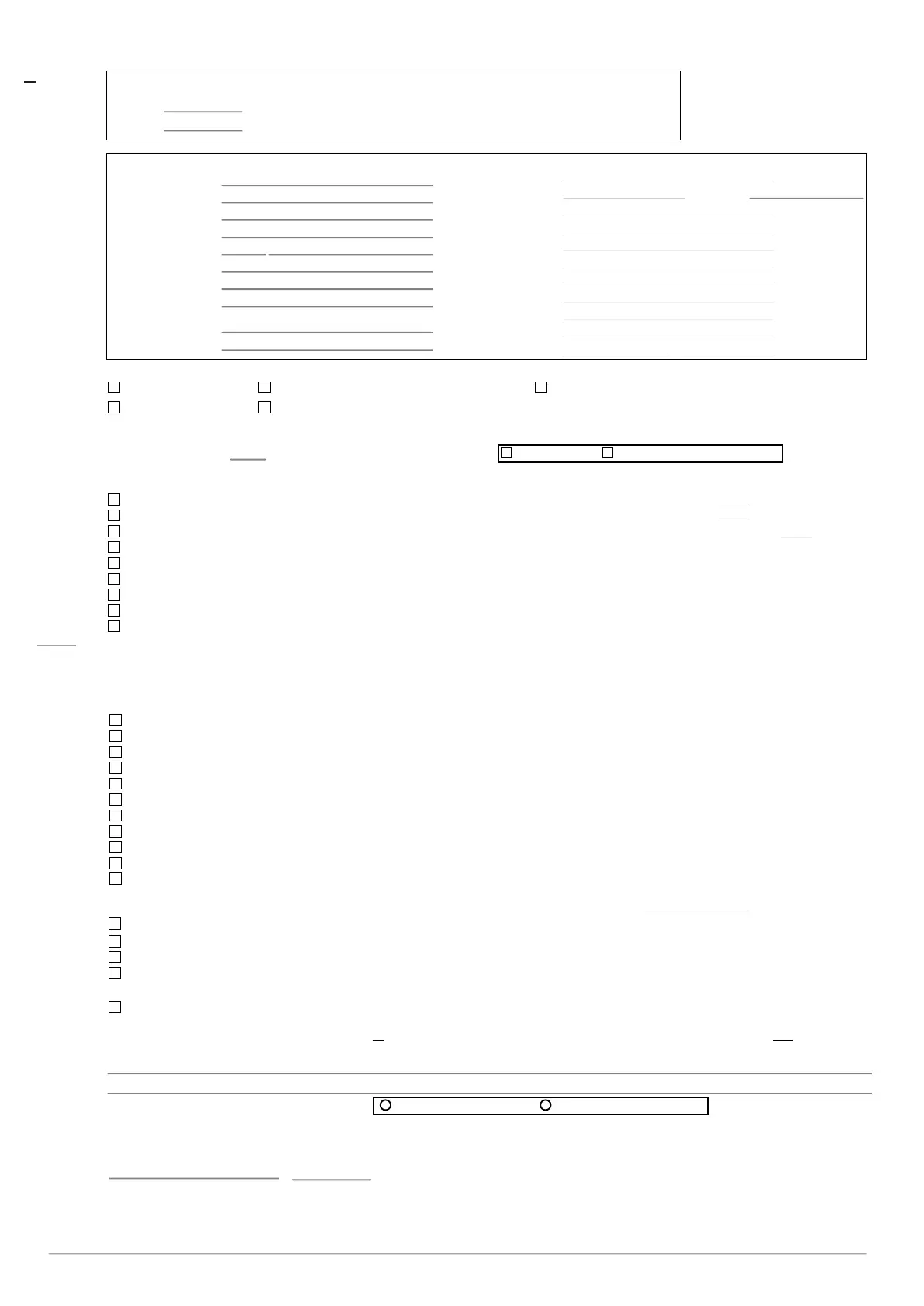

Date:

customer‘s

order number:

company:

address:

department:

Post Code/City:

attending staff:

inspector:

inventory no.:

machine located at:

cost centre:

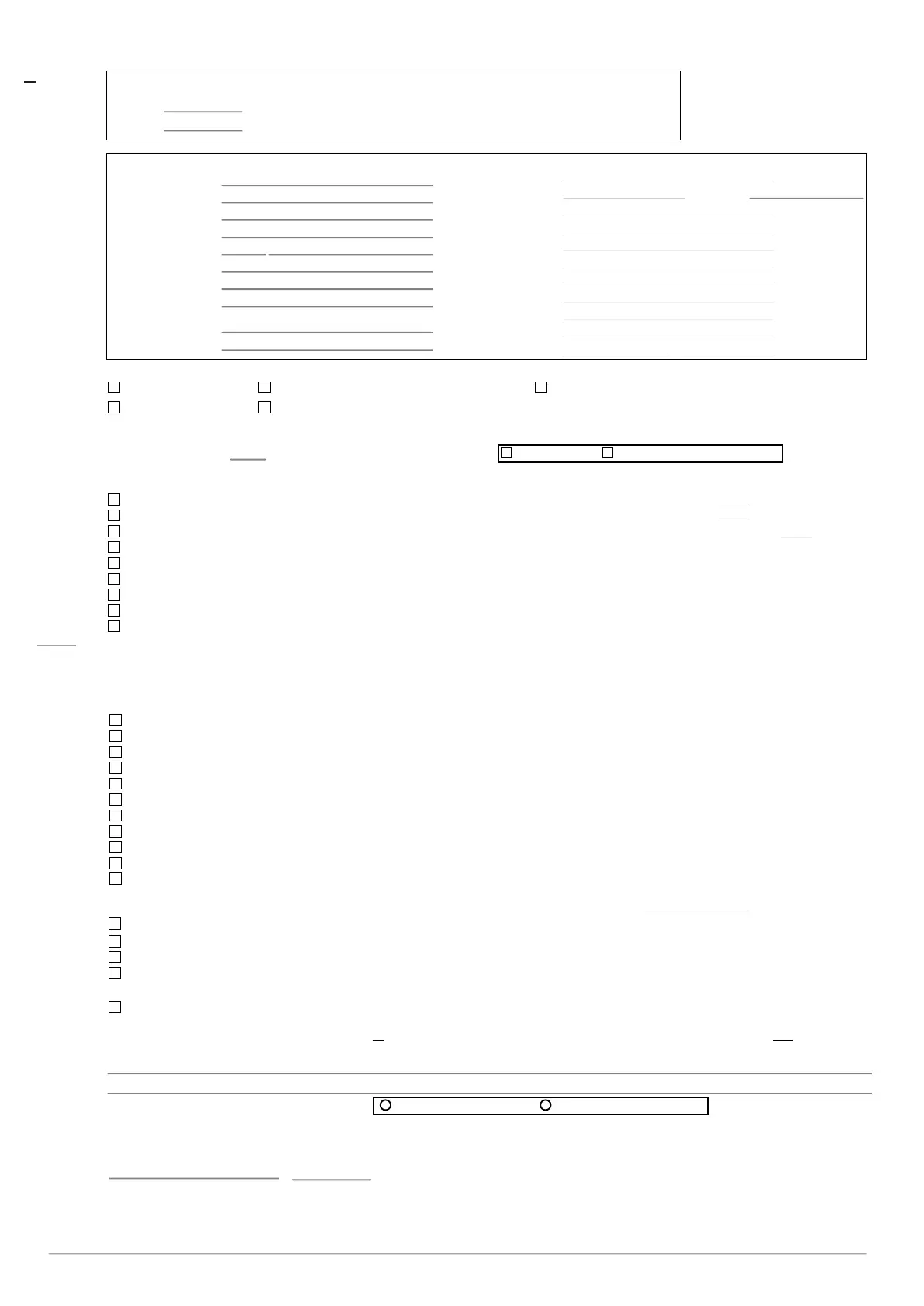

2. Installation:

3. Visual Inspection of the Installation

No.:

Inspection Sheet

Inspection of a press brake safeguarded by a press

brake protection system AKAS®

After viewing of the electrical diagrams, the electrical integration of the AKAS® can be accepted as safe according to

safety class 4 EN 954T.1, under the condition that the machine control is wired exactly as shown in the said diagrams.

3.10 max. work speed:

4.1 The stopping of the AKAS® during the dangerous movement complies with the safety level of safety category 4

4.2 control elements : OK

4.3 closing movement during foot operated motion with AKAS® only possible when foot pedal remains pressed down

4.4 interruption of the AKAS® during fast speed: OK

4.5 interruption of the AKAS® during work speed: OK

4.6 operation mode „foot-fast motion“ is possible only when AKAS® is activated

4.7 AKAS® is switched off in all operation modes where AKAS® is not activated

4.8 Muting signal is given if the gap above metal sheet corresponds to distance between „lower edge E2 and tool tip+2mm“

4.9 Muting signal from valve position signal during work stroke or AMS

4.10 Muting signal monitored by LSUW N1 Muting K switching unit , safety PLC or machine control.

4.11 Muting signal monitored by machine control

4. Cooperation between the AKAS® system and the machine

5. Comments

badge issued badge not issued

Inspection Badge:

...........................................................................,

first inspection

regular inspection

maintenance contract existing

cost estimate of maintenance contract requested

regular inspection requested

1. Inspection:

machine control by:

type of control:

Muting box no.:

detection range: m

AKAS® no:

machine builder

machine type:

3.1 correct electric connection

3.2 cables damage free

3.3 strain relief at both sides of cable loop

3.4 cable protected against all mechanical damages by metal sheet

3.5 correct position of vertical light grid (not too far behind from bending line)

3.6 correct position of vertical light grid (distance sufficiently behind the bending line)

3.7 transmitter beams are parallel to the ram

3.8 work speed < 10 mm/s

3.9 test with test rod passed

mm/s

3.11 max. fast speed:

3.12 Overrun traverse of the AKAS® is:

when interrupted during fast speed motion

mm

mm/s

AMS no:

Sensors 1/2, nos:

phone:

Fax:

inspecting company:

Serial no..

transmitter receiver

optional swivable holder at:

Muting point in mm:

If tops 3 and 4.1 - 4.10 are not completely ticked, or if one or more of the tops 4.21- 4.24 are ticked, the AKAS® installation is not

in a faultless condition. In this case, the protective effect by the system is not completely provided.

4.30 The protective effect might be cancelled by a malfunction of the press.

4.22 Muting signal unsafe

4.21 PLC input is controlled by ESPE output.

4.23 Safety level of the following machine control is lower than ESPE

4.24 Secondary control is single channel

The inspection refers only to the functionality check of the AKAS® according to the regulations. It does not replace the safety check

of the machine itself. All modifications of the AKAS® or of the machine may impair the protective effect of the AKAS®. In this case,

the inspection must be repated.

AKAS® , Safety PLC e.g. FPSC or machine control

Loading...

Loading...