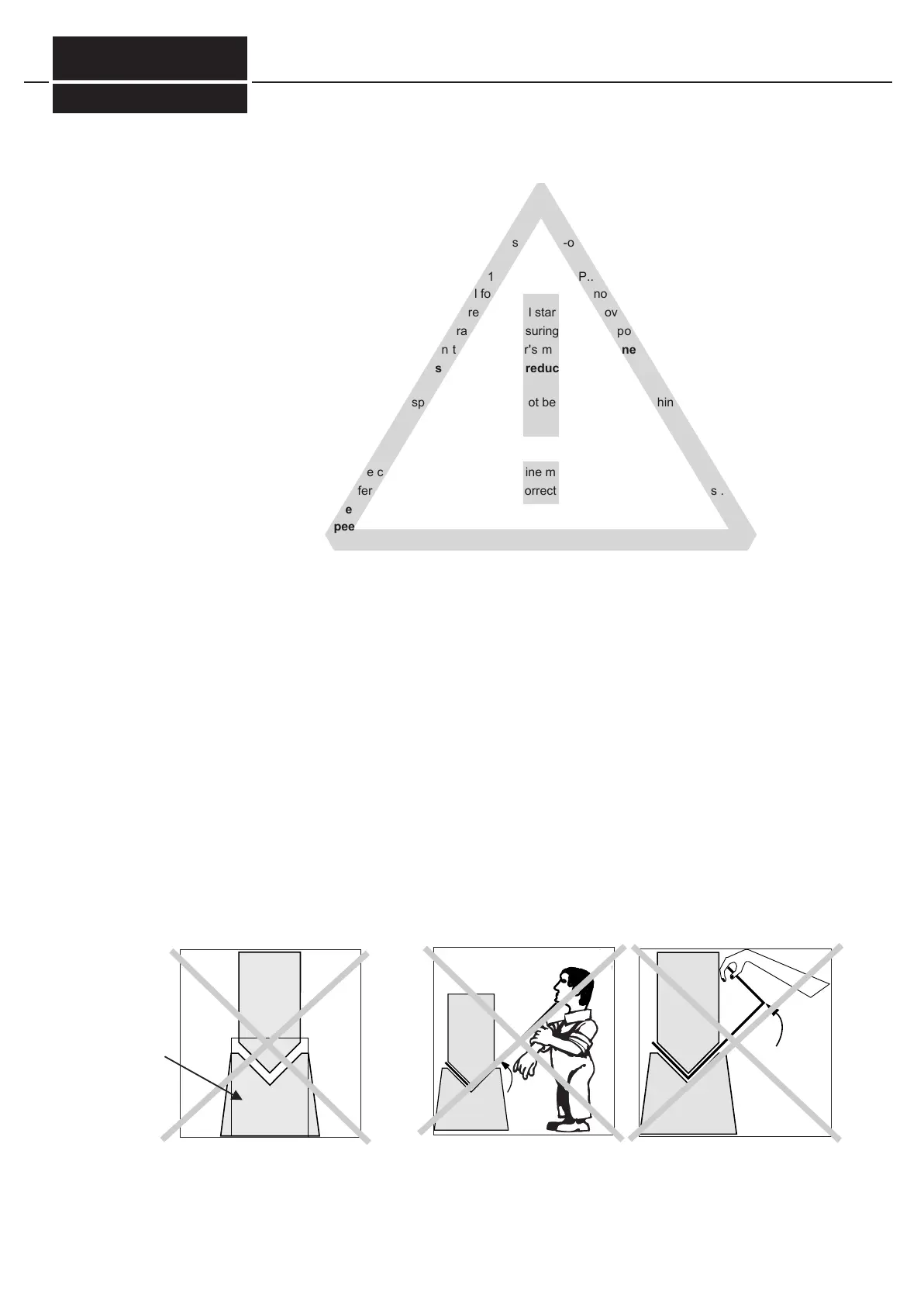

1. Use only tools with the same height in the same fixing on the press. All utilized tools must have one common bending

line.

2. According EN 12622 the press brake safety safety system AKAS® is designed specifically and only for the use of “V”

type tools.

3. Stoppers, which are mounted at the matrix, lead to a premature switching-off of the downward movement

4. The maximum allowable overrun traverse of the machine: 11mm / AKAS®-3P..

The press must have an automated overrun traverse control for the first stroke. If not, it can be realised by the AKAS®-3PF

and a cam controller or by the Fiessler AMS-system . Before the initial start-up, the overrun traverse must be checked either by

using the test rod (see page 9) or by using an Overrun Traverse measuring device. (upon customer's request, Fiessler Elektro-

nik will perform the Overrun Traverse Measuring on the customer's machine.) If one results of 10 consecutive measure-

ments is larger than 11mm / AKAS®-3..., the fast speed must be reduced.

5. Due to the missing sychronization during fast speed, AKAS® cannot be used for two machines aligned in parallel

(e.g. "tandem press brake") .

6. Muting of AKAS.

During the slowspeed closing movent the control system of the machine must send the mute

signal to the AKAS receiver. Please refer page 15 how to setup the correct blanking / mute point values .

The control system of the machine must reliably guarantee, according to safety category 4,

that from this point the stroke speed is <= 10mm / s.

6.1 Bending boxes with AKAS If the “boxbending” mode of AKAS is activated the

blanking and the muting signal must be activated before the receiver element E2 (for Details see page 12) is interrupted.

Please refer page 15 columns “boxmode” how to setup the correct blanking / mute point values

for boxbending mode.

6.2 Bending flat sheets with AKAS Before the blanking signal is sent to the AKAS receiver

any of the receiver elements E1 and E3 – E6 must not be interrupted by the sheet or the

lateral die cover (for Details see on page 10)

But the receiver element E2 must be interrupted by the sheet or the lateral die cover.

The blanking signal can be a output signal from the machine NC.

The closing stroke can continue in high speed until the mute point is reached

7. The protection of a pressbrake by the AKAS® does not permit bending in the bottom of a box inside the box in fast

speed.

8. The AKAS® does not protect: -if the machine is only run in the work speed, or AKAS will be

interrupted during fast speed and the stroke will be continued in

work speed

-if the overrun traverse of the press brake is too long

-from squeezing during the bending operation

-if the mutinglamp is constantly on

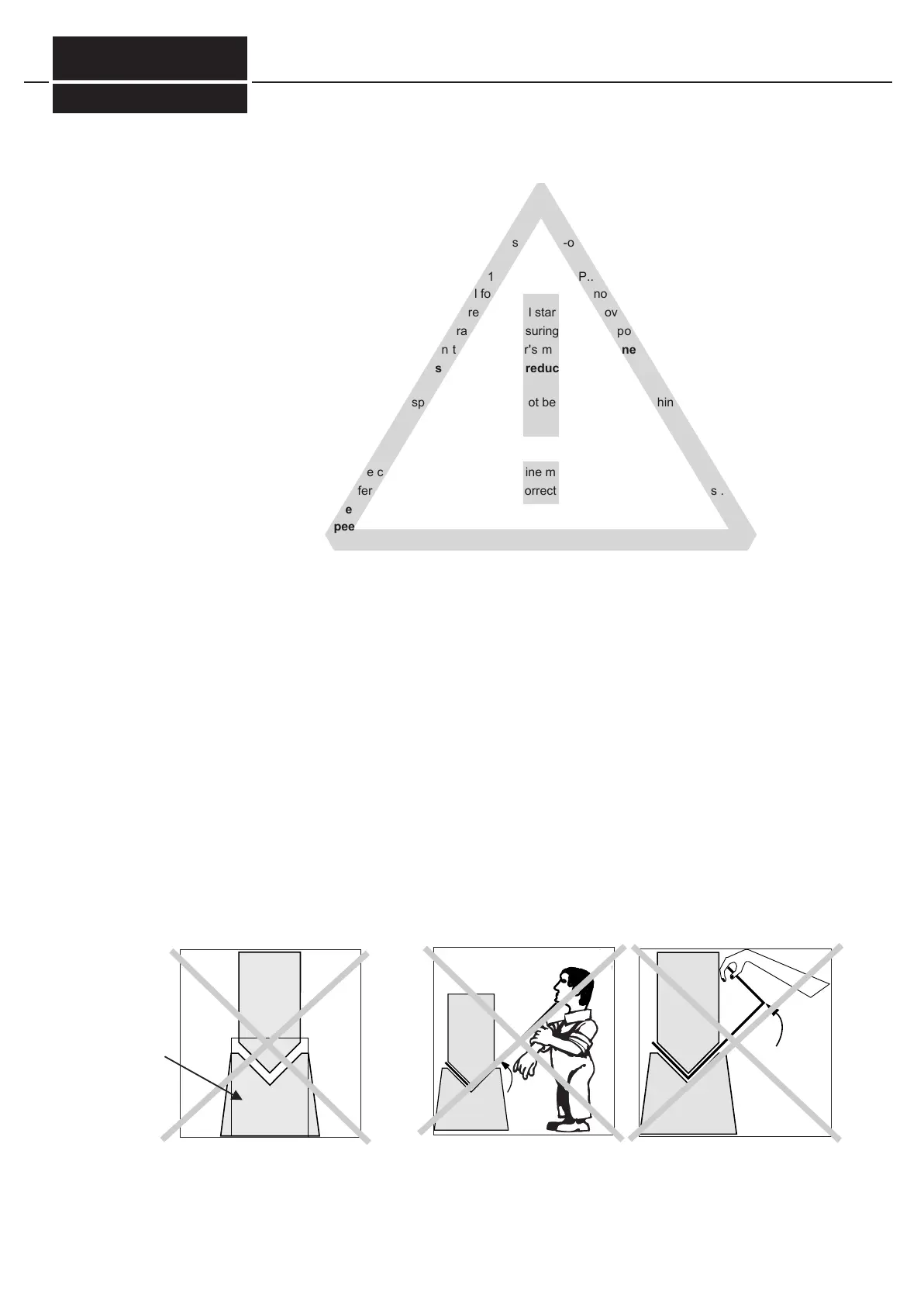

-if the lateral stencil cover is higher than the top of the die ans the blanking

signal (SP) is set to this wronh position of the leteral die cover.

See pic 6/3 together with a wrong SP setting

9. The hazardous state of the machine must be terminated by the sensor function.

10. The safety level (class 4) of the accident preventing light barrier should at least correspond to the safety level of the control

system of the machine.

11. Laser beams may be deviated due to air currents, this may cause unwanted and unforeseen machine stops.

Therefore the machine must be erected at a place free of air currents.

Safety Instructions

2

Fig.6/ 1

Fig.6/ 2

Prerequisites for using the press brake protection AKAS®

Doku Nr. 1379 Stand 27.1.2017 /Aui

FIESSLER

E L E K T R O N I K

Fig.6/ 3

leteral die cover

Loading...

Loading...