Page 1

OWNER’S MANUAL

www.fimcoindustries.com

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049

Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440

[5194678 (01/22)]

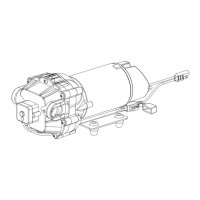

12 Volt, 1.2 GPM, 60 PSI

Diaphragm Pump

Model: HFP-12060-111

(5281370/5151086)

Installaon and Service

Informaon

Fimco High-Flo High Performance pumps are designed to pump water and aqueous soluons of common pescides. They are not

designed to pump petroleum products or other ammable materials. They are not designed to pump bleach soluons. Use of this

pump for petroleum products or bleach soluons will void the warranty. When pumping liquids other than water, the pump

should be ushed out with a cleaning soluon, such as Fimco Tank Neutralizer & Cleaner, or clean water mixed with a good grade

dish soap aer each use to prolong pump life.

This High-Flo High Performance pump is equipped with a demand switch that reacts to outlet pressure and shuts the pump motor

o at a factory set pressure limit of 60 PSI. When the pressure drops below this preset limit the switch allows the pump motor to

start again.

High-Flo High Performance pumps are self-priming. Vercal prime will depend on the viscosity of the liquid and sucon line size.

Minimum recommended sucon line size is 3/8 inch. Make sure all hose clamps are ght before tesng or spraying for the rst

me. The installaon of a 50 mesh strainer is recommended to prevent debris or other foreign material from entering the pump

and causing pump failure. The pump should be mounted in a dry and adequately venlated area. The pump can be mounted

horizontally or vercally. If mounted vercally, the pump head should be down and the motor should be up. Your pump has two

male 3/8” hose barb ngs molded into the pump head. Use exible hose or tubing to connect to the inlet and outlet ports on the

pump. This minimizes stress on the pump head. Never use rigid pipe connecons. Do not compress the feet. Overghtening will

reduce the ability to isolate vibraon & noise.

Your pump is rated at 1.2 GPM @ open ow. If the discharge plumbing is very restricve or nozzle ps are undersized, the back

pressure will cause the pump to cycle rapidly. This rapid cycling will increase the operang temperature of the motor and the

amperage draw on the power supply. Extended use with this cycling will cause premature failure of the pump.

Your pump is designed to run o of the baery of your ATV, lawn tractor, or other vehicle with a 12V system. If using a stand alone

baery, use a deep cycle RV or marine baery.

The pump should be winterized before storage, by pumping a soluon of RV anfreeze through it, and the enre plumbing system.

Retain a copy of receipt for your pump.

As it will be required to validate any warranty service.

High-Flo High Performance Pumps are warranted against manufacturer or workmanship defects for Two (2) years from date of

purchase for home owner usage and 90 days for commercial usage.

See Page 6 for Warranty Informaon

WARNING: To reduce the risk of injury, the

user must read and understand the operator’s

manual before using this product.

WARNING: Cancer and Reproducve Harm.

www.P65Warnings.ca.gov