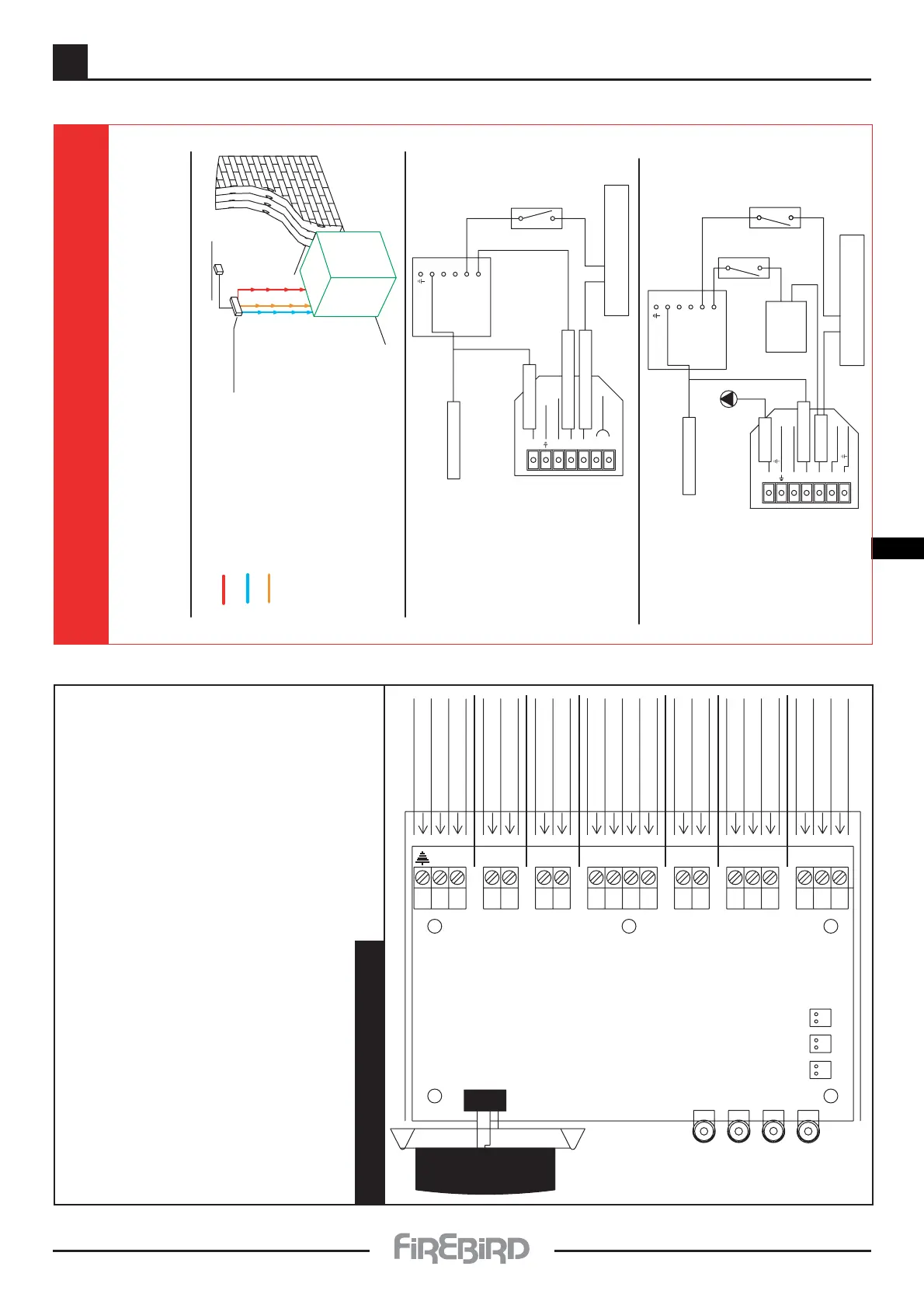

1. Permanent Live To Combi

2. Switch Live For Domestic Hot

3. Switch Live For Central Heating.

Important Re: Wiring Combi Boiler

When connecting the Combi to a remote single channel timer,or programmable room stat,

or a two gang timer, follow instructions shown in diagrams below.

The Permanent Live to a Combi is needed for an over heat thermostat,

and for a Frost Thermostat in the case of the Firebird Combi Pac.

Make sure that the permanent live is connected to the

'mains in' plug and is protected by a 5 Amp. Fuse.

Heat Resistant Cable must be used when connecting

power supply to, and from this boiler.

Remote Timer

Mains Supply

Firebird

Combi Pac

Boiler

2.

3.

1.

Mains Plug Wiring for

Combi and Combipac.

Mains Plug Wiring for Kitchen Utility,

Heatpac & System Boilers.

Use Heat

Resistant Cable

Protect Supply

With 5 Amp fuse.

Permanent Live.

Earth.

Neutral.

Mains Plug

L1 N T1 L2 S3 B4

Switch Live

Earth.

Neutral.

Mains Power Supply

MV.

Refer to

manafacturers

instruction

Tank

Stat.

Zone Valve.

Refer to manafacturers instruction

Two Wire

Volt Free

Room Stat.

System Programmer.

DHW.

CH.

Neutral.

Pump Live

Zone Valve.

Refer to manafacturers instruction

Two Wire

Volt Free

Room Stat.

System Programmer.

DHW.

CH.

Neutral.

Mains Power Supply

Combi

Mains Plug

Permanent Live.

Earth.

Neutral.

L1 N T1 L2 S3 B4

Hot Water Switch Live

Room Stat

Heating Timer Switch Live

Use Heat

Resistant Cable

Protect Supply

With 5 Amp fuse.

Firebird Enviromax Condensing Range

3

23

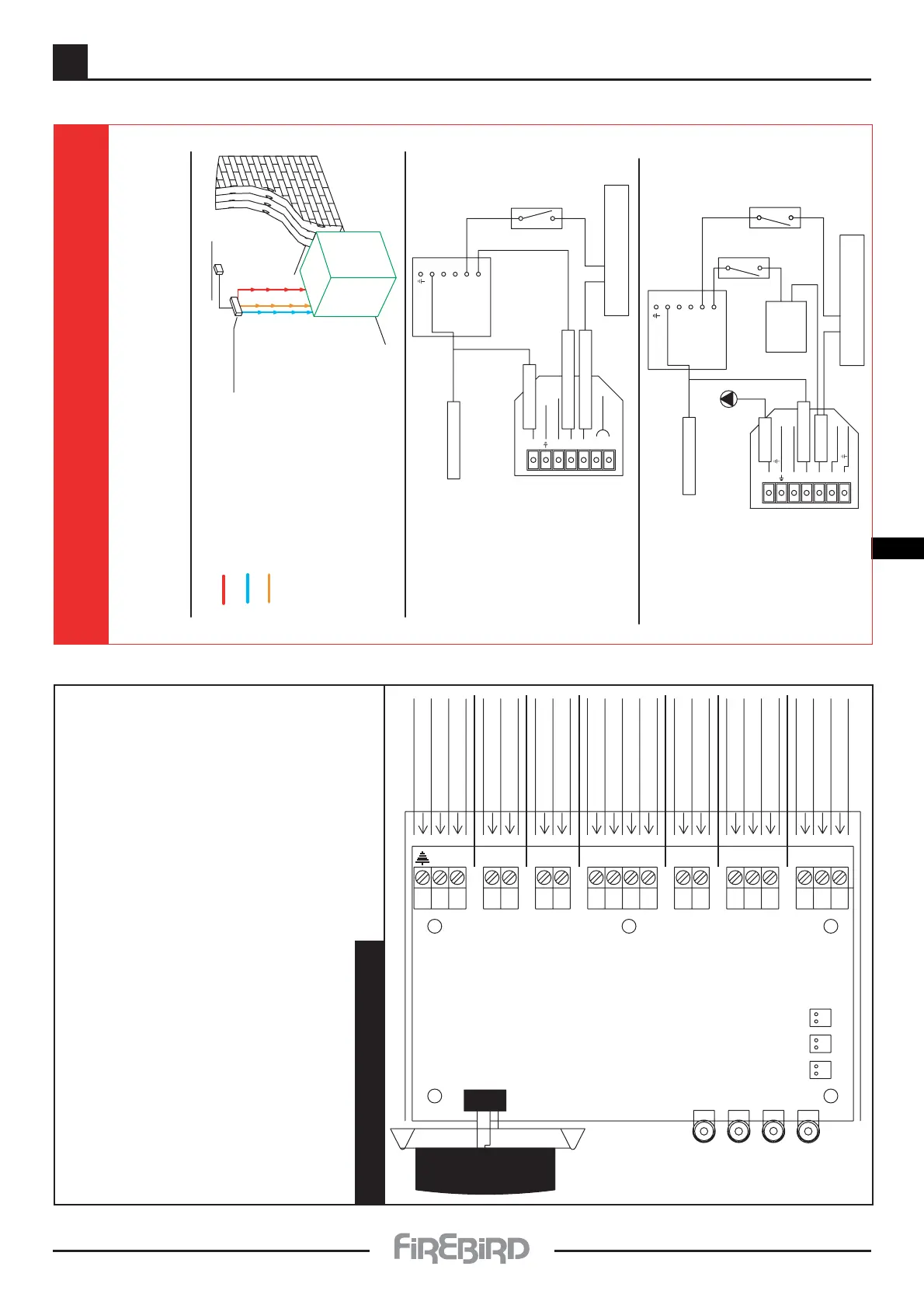

3.3 - COMBI - WIRING

Combi PCB Board

Earth. From Panel Body.

N. Mains In Plug Neutral.

L1. Mains In Plug Live.

DHW. Pump Neutral.

DHW. Pump Live.

CH. Pump Neutral.

CH. Pump Live.

Timer Permanent Live.

Timer Neutral.

DHW. Timer Switch Live.

CH.Timer Switch Live.

Room Stat 2.

Room Stat 1.

Burner Lockout.

Burner Neutral.

Burner Live.

High Limit No.2.

High Limit Comm.

High Limit No.1.

D.H.W.

C.H.

Limit.

Lock out.

Flow.

Boiler.

Tank.

19 2120

1 2 3 4 5 6 7 8 9 101112 1314 1516 1718

IMPORTANT

1. Ensure all wiring and earthing is carried out strictly to best practice and national standards.

2. Protect supply with a 5 amp fuse.

3. Use Heat Resistant Cable.

4. Route and Secure All Leads Away From Hot Parts Of This Appliance.

WARNING:

The manufacturer cannot accept responsibility for any damage to persons, animals or property due to error in

installation or in the boiler. Or due to improper or unreasonable use or non-observance of the technical instructions

enclosed with the boiler, or due to the intervention of unqualified personnel.

ELECTRICAL SUPPLY:

The boiler and controls require 230V 1 phase 50Hz electric supply protected with a 5amp fuse.

THIS APPLIANCE MUST BE EARTHED.

A qualified electrician must carry out all electric wiring in accordance with current I.E.E Regulations and any local

regulations which may apply. The mains electrical supply must be taken from a double pole isolating switch with

a 5amp fuse, positioned somewhere close to the boiler. Heat resisting cable must be used which can be routed into

the boiler through the access provided on either side of the base. Ancillary controls may be provided for with

terminal connections in the control panel.

Loading...

Loading...