Firebird Enviromax Condensing Range

3

16

3.2 - DOMESTIC HEATING & HOT WATER

Hot and Cold taps, mixing valves and fittings must be

suitable for operating at mains pressure up to 10 bar

Bidets with the supply of hot and cold mains water are

permitted if they are of the over-rim flushing type and

have shrouded outlets which enable them to have

temporary hand held spray attached. Showers of loose

headed or flexible type must be fixed so that the head

cannot fall closer than 25mm above the top edge of the

bath to prevent it immersing into the bath water.

Alternatively the shower should have a double check

valve incorporated at the point of the flexible

connections.

WATER FLOW REGULATION

The flow rate of water from individual taps may be

affected by any of the following:-

1. Number of taps in use at one time

2. Cold mains pressure

3. Diameter and length of pipework in the

domestic water circuits within the dwelling.

4. Excessive flow from 3/4” bath taps in a house

system converted to mains water supply.

It is recommended:-

A. To ensure that the mains water connection to

the appliance is the first connection from

the mains on entering the dwelling.

B. Where flow starvation is encountered that flow

restrictors or balancing valves are fitted

at supply outlets.

* The boiler has circulating pumps fitted therefore no

other is normally required. They are factory set at

maximum output.This setting should not be altered

on the domestic hot water pump as production of

domestic hot water may be adversely affected.

SYSTEM FILLING, TESTING AND MAKE-UP

Introduction

Mains cold water is supplied through the boiler

pipework to two separate circuits operating at different

pressures.

Circuit One

This is the Radiator Heating System including boiler

and primary tank which is filled from mains supply via

flex filling loop (see - Method A) within boiler to a

pressure determined from system static head,

expansion vessel size and system water volume. This

flexible filling loop should be disconnected when

boiler and system are filled and checked, See

diagrams - Method A & Method B).

Circuit Two

This is the domestic cold water supply through the

boiler plate heat exchanger via domestic hot water

pipework direct to hot taps. This works at full mains

pressure or if this is excessive at a reduced pressure

controlled by a mains pressure reducing valve to a

pressure acceptable to householder and satisfactory for

the correct operation of Combi C Boiler System.This

mains pressure reducing valve is not supplied with

boiler, but will be available from a local supply

merchant.

System filling should take place slowly and can

be done by either of the following methods:-

Manual Filling

The Firebird Combi C comes with this system built into

the appliance. It consists of a flexible hose connection

with a butterfly shut off valve at each end and a double

check valve assembly at boiler end. To conform to

requirements of BS 7074 Part I and local water Authority

Bye Laws, the flexible hose should be disconnected at

one end when filling has been completed and checked.

Two end caps are supplied and should be fitted to

disconnected ends as a safety precaution against

inadvertent opening of ball valves.

Pressure gauge on Control Panel should be checked

occasionally when system is cold. Refill to initial fill

pressure if necessary. Should this be a frequent

occurrence, complete system should be checked for

leaks.

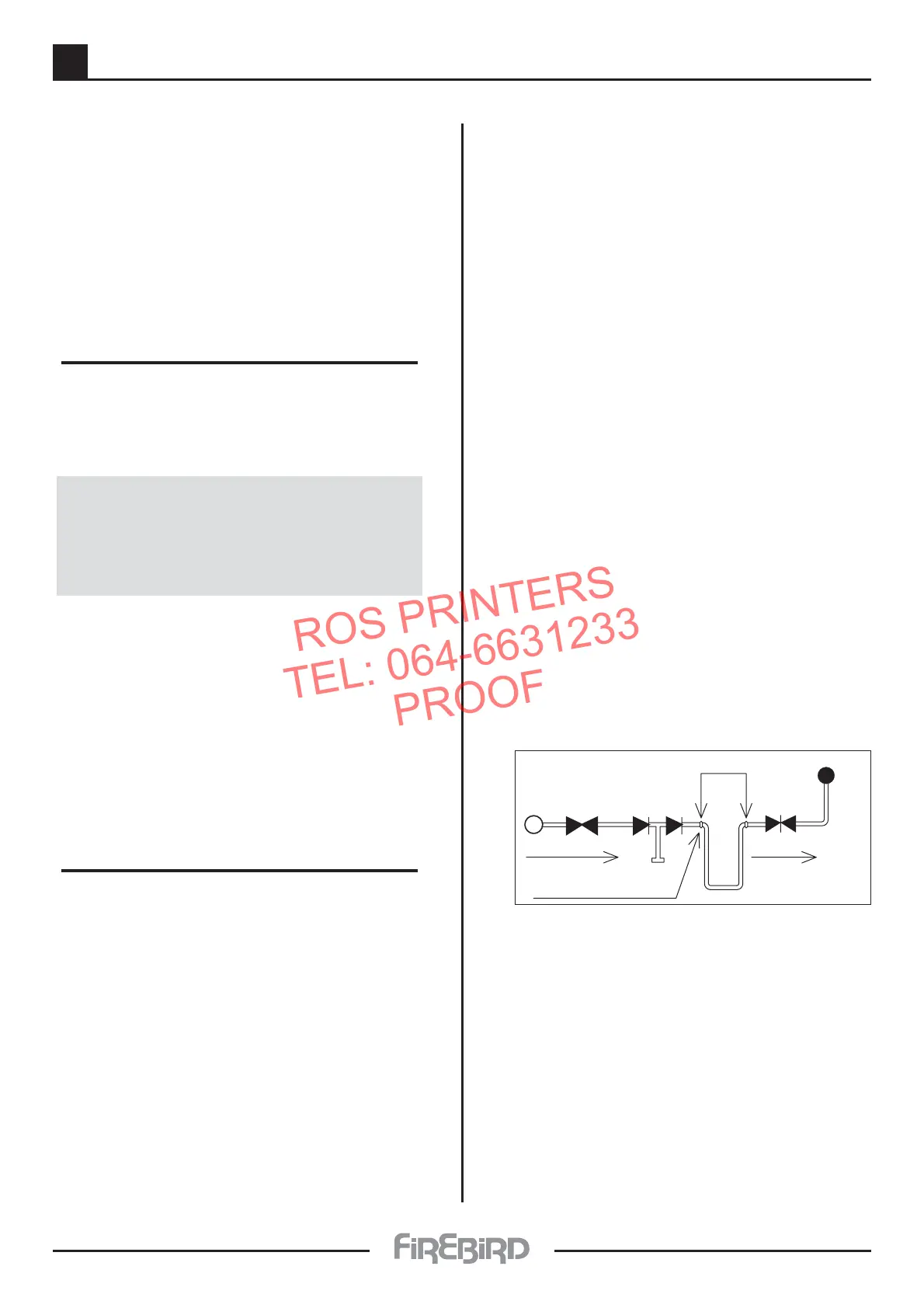

Automatic Filling

Automatic System filling may be made with a feed and

make-up cistern connected through a double check

valve and stop valve assembly to the return side of the

heating system as close to the boiler as is practical.This

cistern should be located above the heating systems

highest point to give a minimum static head of 300 mm

between it (highest point) and cistern. The manual

filling system fitted to boiler should then be

disconnected and connection points blanked off.

This system has the advantage of automatic water

make-up in the event of system pressure loss due to air

elimination and minor leaks. In any case control panel

pressure gauge should be occasionally checked.

Loading...

Loading...